Description

*This version of Blu is for Continental Europe, Ireland, Iceland, Ukraine, Turkey. Shipping via EMS Global (Deutsche Post)

While we recommend printing Blu at temperature 25C or above, a heater is not required. Please refer to the user guide for more detail.

*Prices are in USD and 8K Compatible

Introducing Blu Clear V2 by Siraya Lab, an easy to use a tough resin that performs under stress. It balances strength and hardness and is ideal for making functional parts that are strong yet with some flexibility. Unlike many resins on the market that are too brittle to handle even the slightest drop, Blu Clear has excellent mechanical properties that can withstand forces without breaking easily. We were able to make a hook with it and pull up 20kg weight without breaking. Imagine the kind of projects you can do with it. Check out following test by Paul G

Blu Clear V2 has the almost same formulation as Blu and is designed to print fast with a high success rate on LCD/DLP printers. (not developed for laser SLA) Unlike many engineering resins, it is very easy to clean with common alcohols and post cures quickly as well. It has excellent resolution, primes well, and is used by model makers to create sculptures as art pieces. And it does not smell so it wouldn't stink up your workplace.

Blu has been used on Anycubic Photon, Zortrax Inkspire, Wanhao D7, Phrozen Shuffle and Xl, Dazz and other LCD printers.

Its mechanical property:

Tensile Strength 39Mpa

Shore D 85

Young’s Modulus 1500Mpa

Elongation At Break: 25%

Check out Stefan at CNC Kitchen's tests on Blu

So whether you are a product developer, model maker, or new to resin 3D printing, let Blu bring your creativity into reality.

Reach and ROSH Certification: Click here to view

Estimate shipping

Please note

Estimate shipping will be calculated based on the products in the cart.

Payment & Security

Siraya Tech Tough Resin - Blu

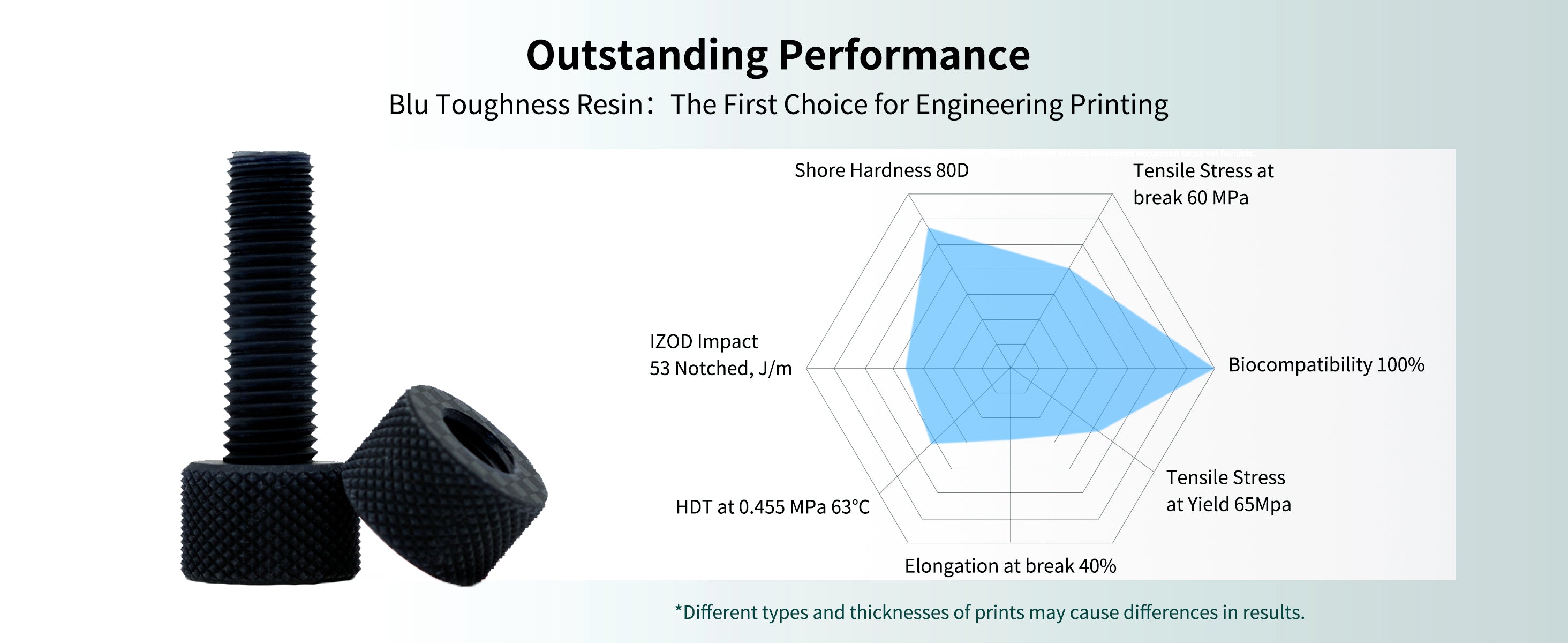

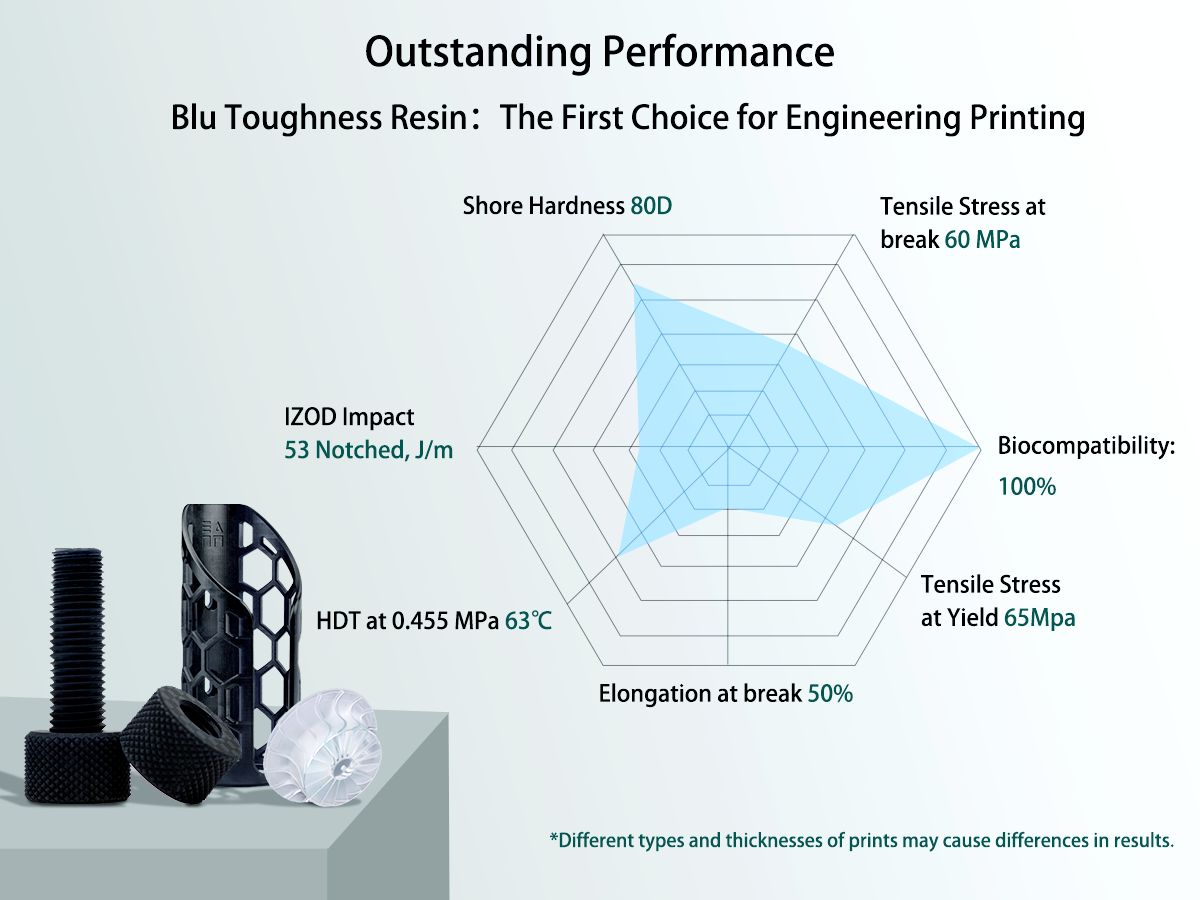

If you want a resin with an excellent balance of hardness and toughness, Tough Blu is your best choice!

Regular Blu Tough Properties

Shore Hardness 80D

Tensile Stress at Break 50 MPa

IZOD Impact 45 Notched, J/m

HDT at 0.455 MPa 70℃

Elongation at Break 32%

Young's Modulus 1800 MPa

Blu Nylon Properties

Shore Hardness 78D

Tensile Stress at Break 45 MPa

IZOD Impact 53 Notched, J/m

HDT at 0.455 MPa 63℃

Elongation at Break(%) 50%

Young's Modulus 1750 MPa

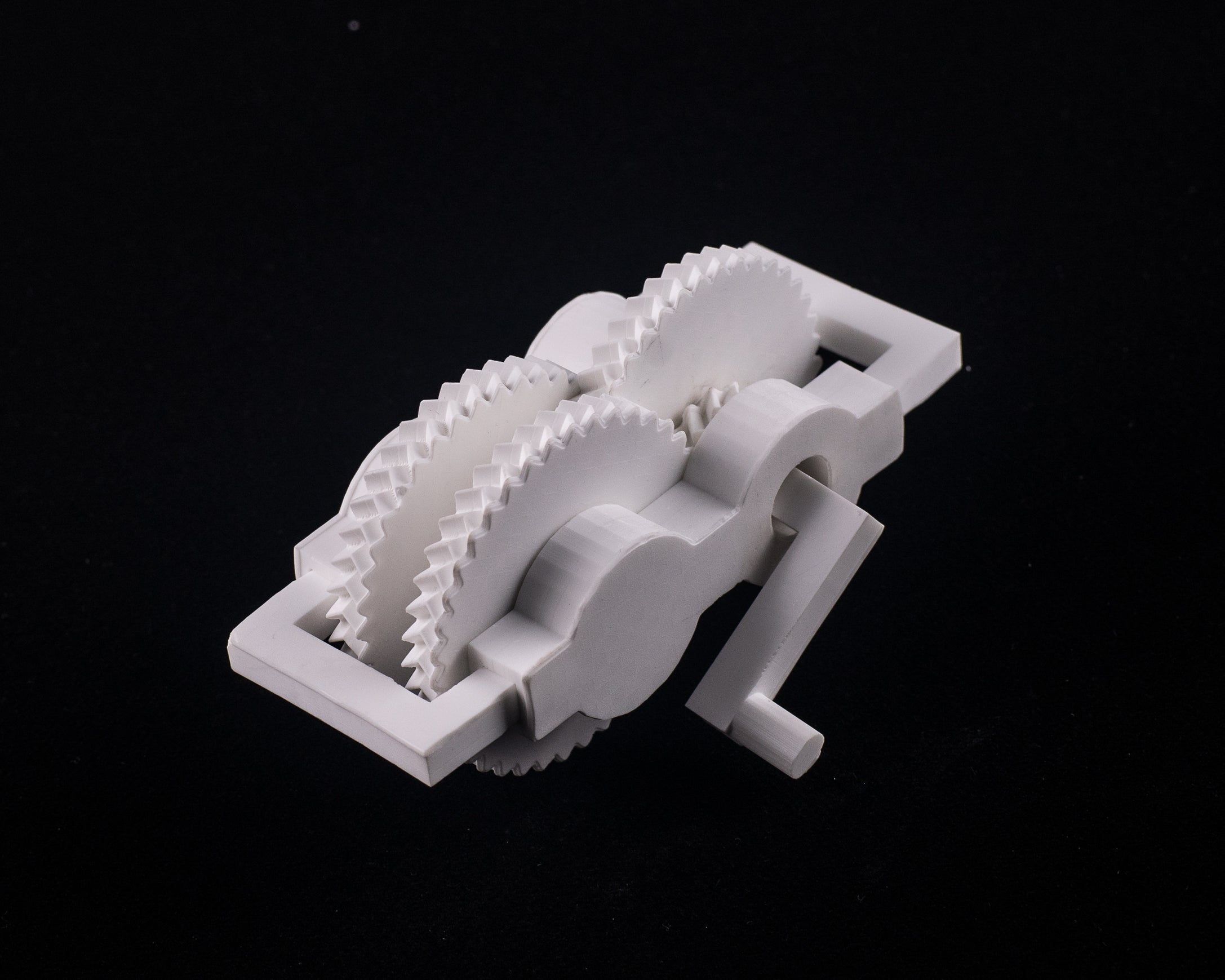

Blu Nylon Mecha Properties

Wear-resistant resin, will not generate powder due to friction, very suitable for gears, joint parts

Shore Hardness 73D

Tensile Stress at Break 58 MPa

IZOD Impact 50 Notched, J/m

HDT at 0.455 MPa 65℃

Elongation at Break 37%

Young's Modulus 1900 MPa

Blu Easy Grey

Shore Hardness (D) 75D

Tensile Stress at Break (MPa) 31

IZOD Impact (Notched, J/m) 42

HDT at 0.455 MPa (°C) 62

Elongation at Break (%) 43

Young's Modulus (MPa) 1000

Blu Lava Black - PC-like strength resin

Shore Hardness (D) 87

Tensile Stress at Break (MPa) 60

IZOD Impact (Notched, J/m) 47

HDT at 0.455 MPa (°C) 75

Elongation at Break (%) 12

Young's Modulus (MPa) 2500

Why choose Blu Tough resin

It balances between strength and hardness and is ideal for making functional parts that are strong yet with some flexibility.

Excellent mechanical properties

Unlike many resins on the market that are too brittle, Blu has excellent mechanical properties that can withstand forces without breaking easily.

Excellent impact resistance

Strong enough to withstand the impact of an accidental drop.

Tappable

It can be tapped without cracking and is dimensionally stable, suitable for the production of various types of engineering parts.

What are the differences between the different colors of Siraya Tech Tough resin - Blu?

Blu Emerald Blue/Clear V2/ Obsidian Black

They have the same mechanical properties, the biggest difference between the three is the color.

These three colors are the regular versions of Blu Tough resin.

Blu Nylon Black

Nylon Black is 25% tougher than regular Blu. The colors of Nylon Black and Onsidian Black are roughly the same.

Blu Nylon Mecha

Blu Mecha adds a new composite material that helps the resin reduce powder generated by friction, making the surface smooth and wear-resistant.

Blu Easy Grey

This is the latest version of Tough resin - Blu. Blu Easy reduces the original printing difficulty and optimizes details, making it more suitable for desktop-level and miniature printing. Blu Easy gives the prints a certain degree of impact resistance.

Unlike many resins on the market that are too brittle to handle even the slightest drop, Blu has excellent mechanical properties that can withstand forces without breaking easily.

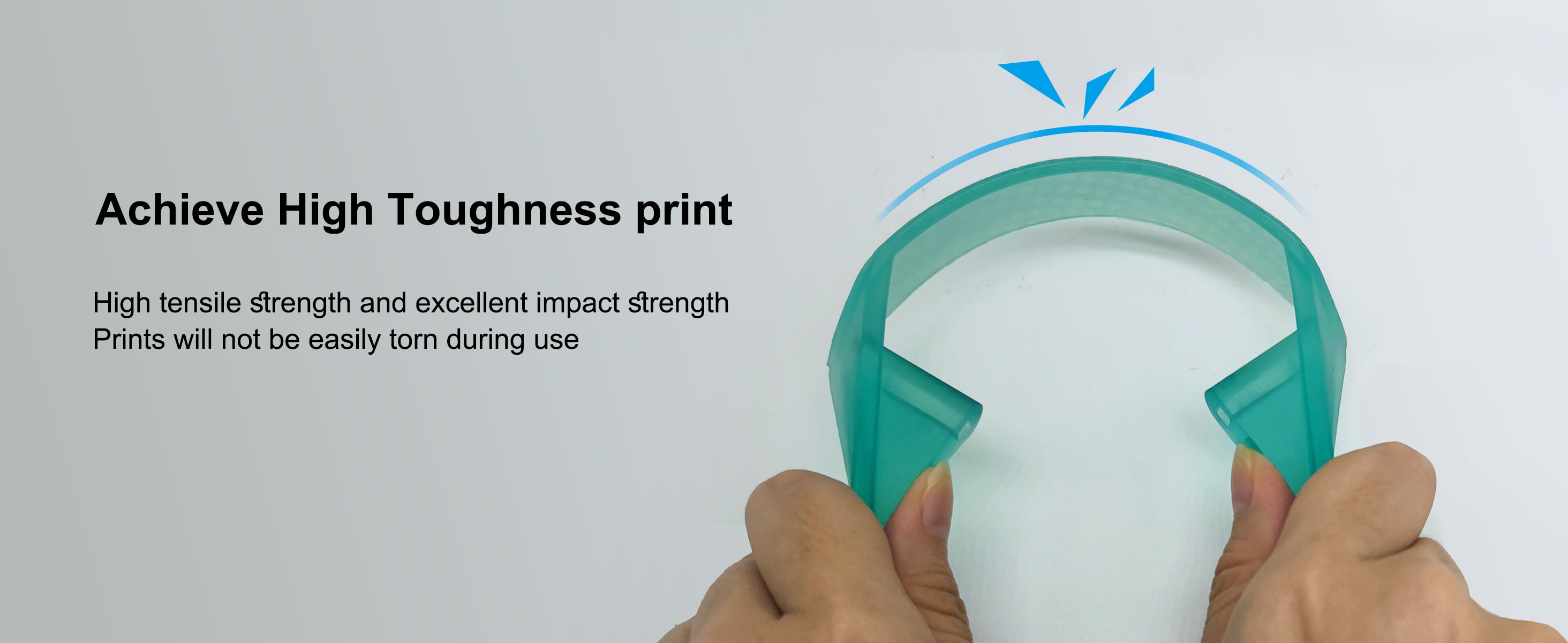

- High Toughness

- Excellent resolution

- Strong and Precise High Resolution

- Precise Prints and No smelly

- Balances between strength and hardness

- Balance between sturdiness and flexibility

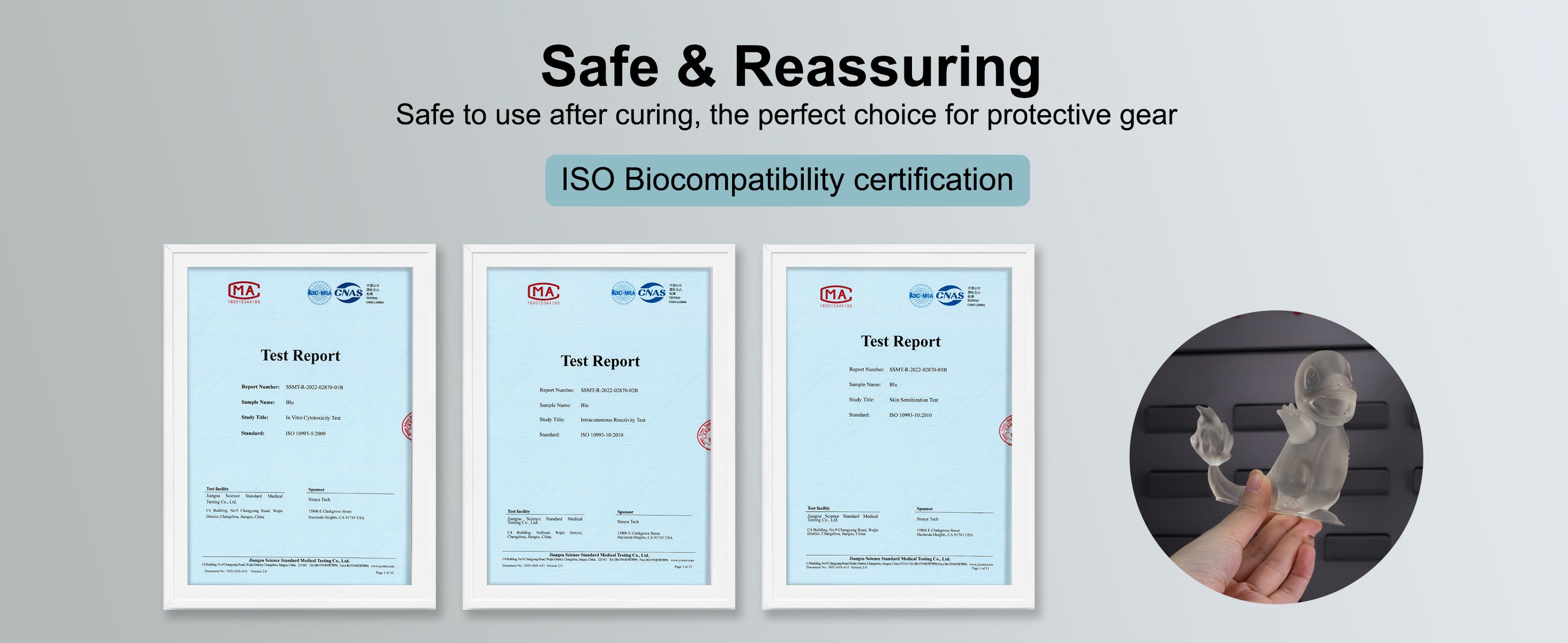

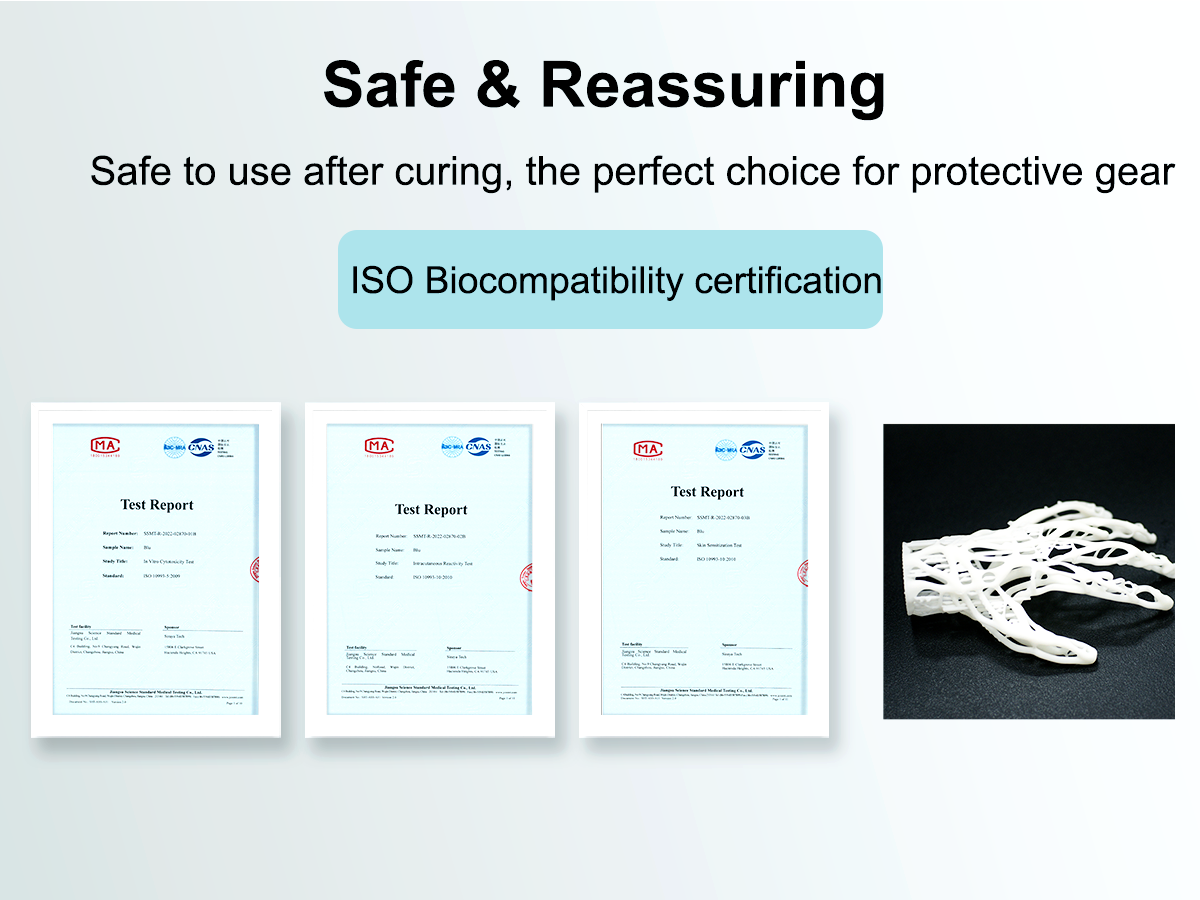

- ISO 19903-10 Biocompatibility certification

High Toughness

Balances between strength and hardness can withstand bending, flexing, and compression. Its high toughness can fully ensure that the prints are not easily broken during repeated bending and stretching.

ISO biocompatibility certification

Blu has passed the ISO 10993-5 and ISO 10993-10 certifications for skin contact, which means it does not cause irritation, inflammation, or sensitization when in contact with human skin externally.

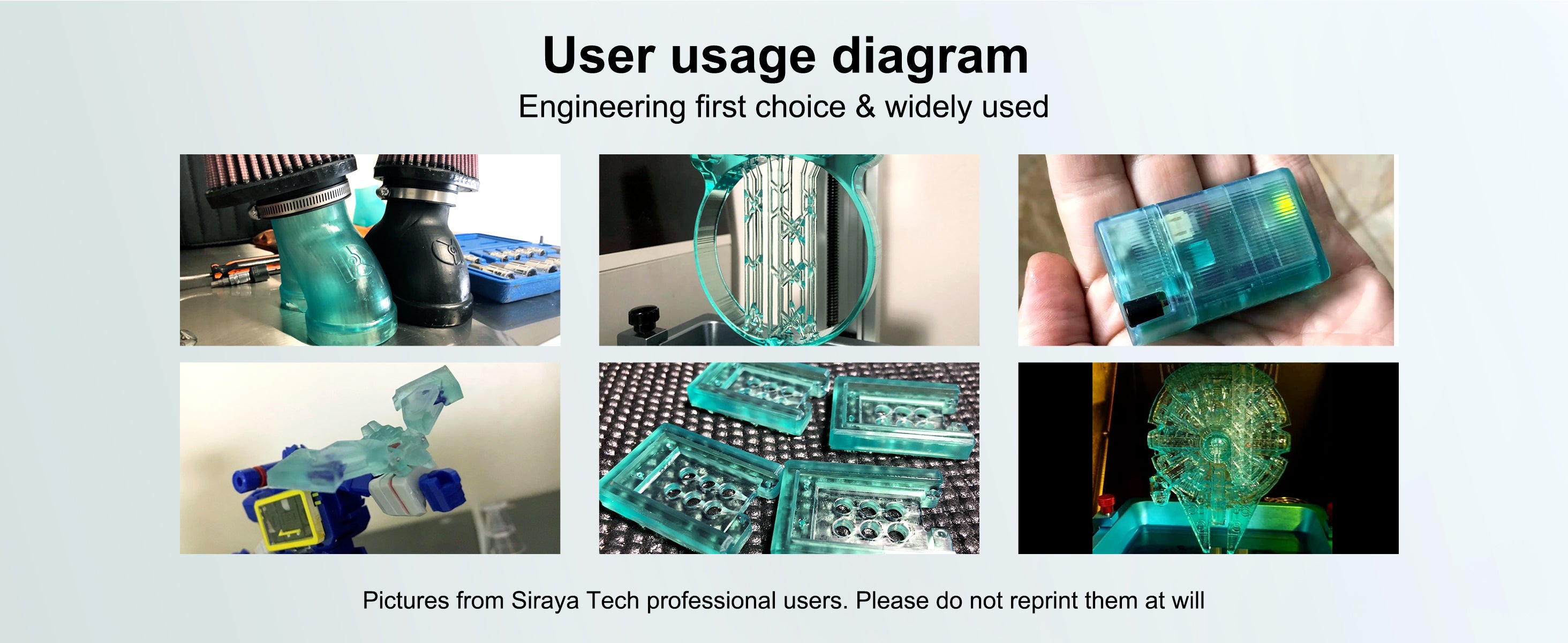

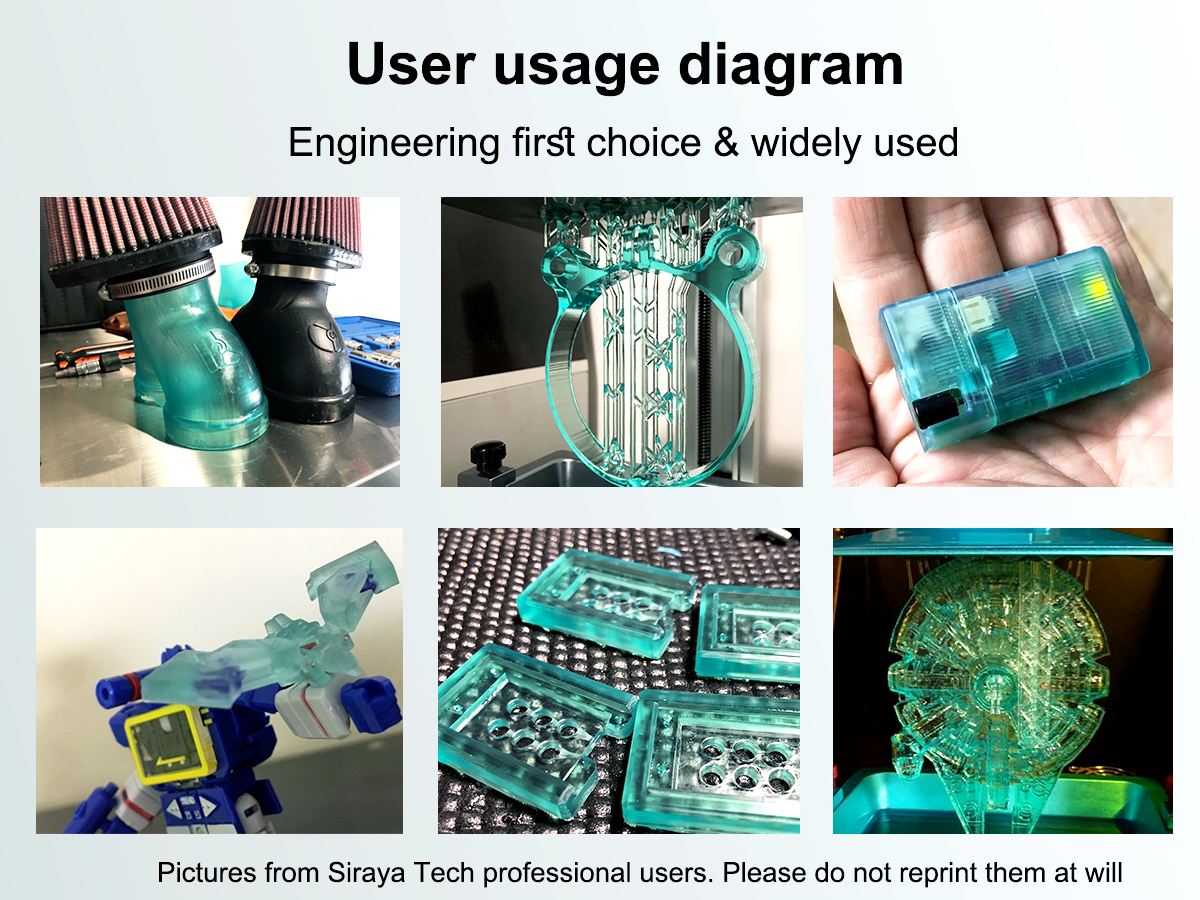

Widely Used Blu Engineering Resin

Blu tough resin is not only suitable for some small functional parts that needed good strength without being brittle, like tools, screws, brackets, bases, etc, but also can print pretty 3d models. And is compatible with most LCP and DLP 3D printers and is 8K/12k compatible.

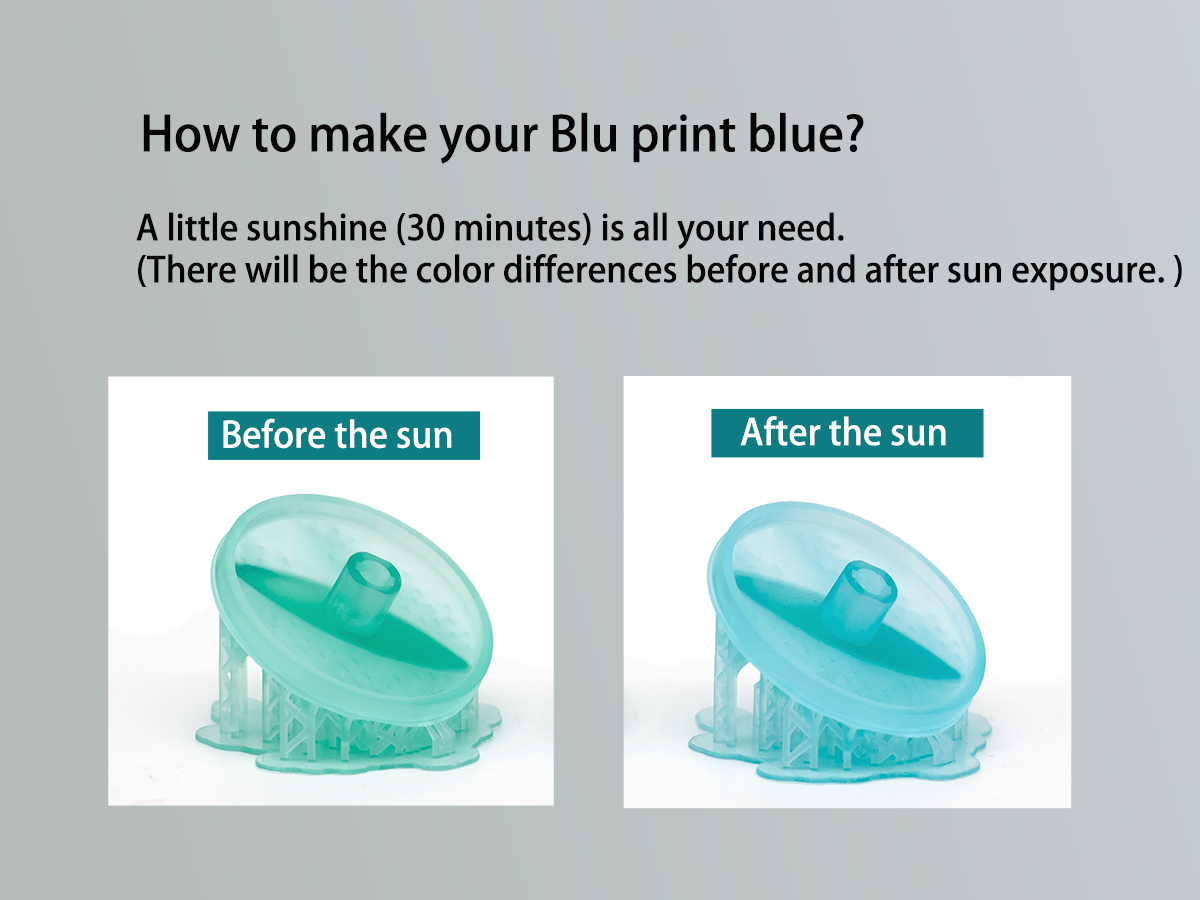

Before and After Sun

How to make your Blu print blue?

--A little sunshine (30 minutes) is all your need.

The model is a beautiful cyan blue before the sun, and it will turn blue after the sun.

Blu Tough resin Video

Blu Lava Black - PC-like Tough Resin

PC-like strength resin that is more suitable for printing farm mass production and End-Use Parts!

Introduce Blu Lava Black

- Exceptional Strength and Stiffness: Engineered for PC-like strength;

- High-Resolution Prints: Provides precise, high-quality prints;

- Excellent Impact Resistance and Tappability;

- Biocompatibility: Certified under ISO 10993-5 / 10993-10.

Application:

- Engineering Prototypes

- End-Use Parts

- Medical Device Prototypes

- Parts that require both strength and precision

Perfect printing, less transparent

Precise printing, meticulous detail!

Blu Lava Black

Blu Test video

Blu Nylon Mecha Display