ABS melting point matters when you mold, print, or heat this plastic. ABS usually melts between 200°C and 240°C. It does not have one sharp melting point because it is not a pure crystal. It softens first, then flows as the heat rises.

You need to know this range so you can set the right temperature for 3D printing or injection molding. If you heat it too low, it will not flow well. If you heat it too high, it can burn or lose strength.

Key Takeaways

- ABS melts in a range of about 200°C to 240°C.

- Proper heat settings help you shape ABS without damage.

- Knowing its heat behavior improves print and molding results.

Want to understand ABS better before you print? Read our guide, What is ABS Filament? Uses, Pros, and Cons for 3D Printing, to learn when ABS is the right choice for your build.

ABS Melting Point Basics

ABS is a common plastic used in many products you see every day. To use it well, you need to know how it reacts to heat, when it softens, and why its melting range matters in real work.

What Is the Melting Point of ABS?

ABS stands for acrylonitrile butadiene styrene. It is a thermoplastic polymer, which means you can heat it, shape it, and cool it many times.

Unlike some plastics, ABS does not have one sharp melting point. Instead, the melting point of ABS falls within a range. Most grades soften and flow between 200°C and 250°C (392°F to 482°F) during processing.

ABS is an amorphous plastic. That means it does not melt at one exact number like ice does. It softens little by little as the heat goes up.

In 3D printing and molding, you often heat ABS to around 220°C to 240°C so it can flow well into a mold or through a nozzle.

Melting Range vs. Softening Temperature

You need to know the difference between melting range and softening temperature. They are not the same.

The melting range is where ABS changes from solid to a thick liquid that can flow. This is the range used in injection molding and extrusion.

The Vicat softening temperature is lower. It usually falls around 95°C to 110°C (203°F to 230°F), depending on the grade. This number tells you when ABS starts to soften under a small load.

There is also the heat deflection temperature (HDT). This is the point where ABS bends under a set weight and heat. For many ABS types, HDT sits near 85°C to 100°C.

These numbers help you see how ABS behaves before it ever reaches full melt.

Why the Melting Point Matters

You need the right ABS melting point range to shape parts correctly. If the temperature is too low, the plastic will not flow well. Your part may have gaps or weak spots.

If the heat is too high, ABS can break down. This can cause bad smell, color change, or weak parts.

The melting point of ABS also affects product use. ABS parts can handle moderate heat, but they can warp if temperatures get close to their softening point.

In cars, tools, and home goods, makers choose ABS because it balances strength and heat resistance. When you know its melting and softening limits, you can design parts that stay stable and safe in real use.

Working with high temperatures? Check out our heat resistant filament collection for materials that hold their shape under stress and deliver dependable performance in demanding conditions.

Factors Influencing ABS Melting Point

Several key factors change how ABS softens and melts. The mix of acrylonitrile, butadiene, and styrene, the additives you use, and the way you heat the material all play a role. Small changes in these areas can shift the melting range by many degrees.

Polymer Composition and Monomer Ratios

ABS is made from three parts: acrylonitrile, butadiene, and styrene. The amount of each part affects how the plastic handles heat.

- Acrylonitrile adds heat and chemical resistance. More acrylonitrile can raise the softening temperature.

- Butadiene adds impact strength. Higher butadiene content can lower heat resistance.

- Styrene gives rigidity and smooth flow when melted.

ABS does not have one sharp melting point like pure crystals. It is mostly amorphous, so it softens over a range, often around 200–250°C during processing.

If you change the monomer ratio, you change how tight the polymer chains pack. Tighter packing usually means better heat resistance. That is why different ABS grades list different melt temperatures.

Additives and ABS Formulations

Your ABS formulation can shift the melting behavior. Additives change how the material reacts to heat.

Common additives include:

- Fillers (like glass fibers)

- Flame retardants

- Colorants

- Plasticizers

Glass fibers can improve heat resistance and raise the heat deflection temperature. Plasticizers can make the material softer and lower the softening range.

Flame retardants may also change how heat moves through the plastic. Each added material affects how the polymer chains move when heated.

When you select an ABS grade, you are really choosing a full formula, not just the base polymer. Always check the data sheet for the exact processing temperature range.

Processing and Heating Rate Effects

How you heat ABS matters. The heating rate can change the measured melting or softening point.

If you heat the plastic fast, it may appear to melt at a slightly higher temperature. Slow heating often shows a lower softening point. Test methods like thermal analysis or hot-stage viewing can give different results because of this.

Your processing method also plays a role:

- Injection molding often uses melt temps near 220–250°C.

- Extrusion may run in a similar range but with steady heat.

- 3D printing settings depend on the grade and printer setup.

Cooling rate after melting can also affect internal stress and final heat resistance. When you control your ABS processing settings well, you get more stable and repeatable results.

Want added rigidity with excellent layer bonding? Explore our PETG CF filament collection for carbon fiber-reinforced prints that deliver strength and dimensional stability.

ABS Melting Point in Practice

ABS does not melt at one sharp number. It softens over a range, so you must control heat with care when working with ABS in real jobs.

Injection Molding and Extrusion

When you use ABS in injection molding, you heat it until it flows like thick syrup. ABS is an amorphous plastic, so it softens over a range instead of melting at one point.

Most grades start to soften around 105–115°C (221–239°F). In molding, you often set barrel temperatures much higher, usually around 200–250°C, so the material flows well into the mold.

If the heat is too low, the part may not fill all areas. You may see short shots or weak spots. If the heat is too high, the plastic can burn, discolor, or lose strength.

In extrusion, you also control temperature in zones. Each zone heats the ABS step by step. This keeps the flow steady and helps you make smooth sheets, pipes, or profiles.

Good temperature control gives you:

- Better surface finish

- Stronger parts

- Fewer defects

- More stable production

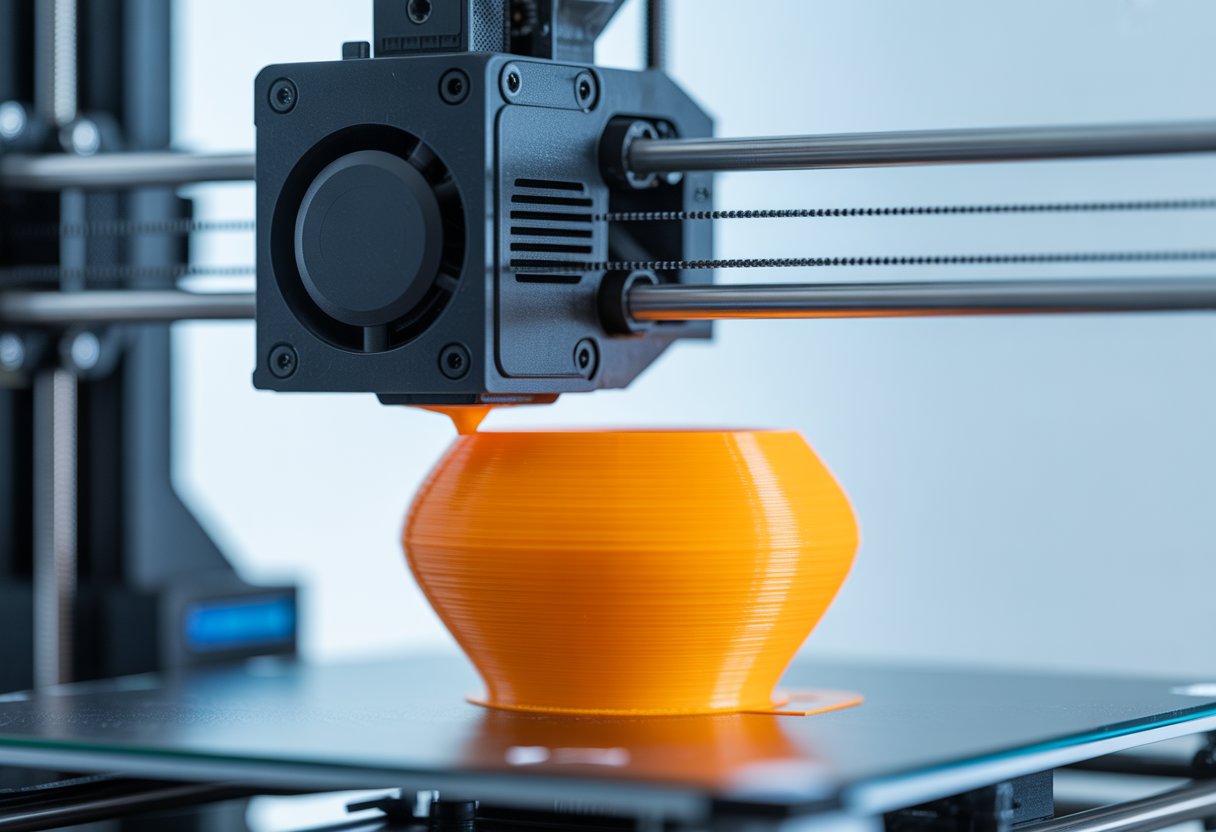

ABS in 3D Printing

ABS in 3D printing needs steady heat and good control. When you use ABS filament, your printer nozzle usually runs around 220–250°C. This melts the filament enough to push it through the nozzle.

You should also heat the print bed. A bed temperature of about 90–110°C helps the first layer stick. Without enough heat, the corners may lift. This problem is called warping.

ABS cools and shrinks as it hardens. That shrink can cause cracks between layers if the room is cold. Many people use an enclosed printer to keep the air warm and reduce stress in the part.

When working with ABS, watch for:

- Warping at the edges

- Layer splitting

- Strong plastic smell during printing

Good airflow and safe setup matter when you print indoors.

Measuring Techniques for Melting Point

You cannot measure a sharp melting point for ABS like you can with some other plastics. Instead, you measure its softening range and glass transition temperature.

One common method is DSC (Differential Scanning Calorimetry). This test shows how the material reacts as heat rises. It helps you find the glass transition, which is often near 105°C.

Another test is the Vicat softening temperature. This method checks when a flat needle sinks into the plastic under heat and load. It gives you a clear number for comparison between grades.

These tests help you:

- Pick the right ABS grade

- Set safe process temperatures

- Avoid heat damage in use

If you change the blend or add fillers, the softening range can shift. Always check data from your supplier before you set your machines.

Looking for reliable materials that print clean and perform well? Visit our 3D printer filament collection to discover a full range of options for every project and printing style.

ABS Material Properties Related to Melting

ABS plastic melts over a range, not at one sharp point. Its toughness, impact resistance, and rigidity all change as heat rises toward its melt flow range of about 220–250°C (428–482°F).

Impact Resistance and Toughness

You choose ABS plastic when you need strong impact resistance. It can take hits and drops without cracking. This comes from the butadiene part of the material, which adds rubber-like toughness.

As heat moves closer to the melting range, that toughness starts to drop. The plastic gets softer and bends more easily. If you heat it too much, it will lose shape and flow.

Before it melts, ABS can still handle stress better than many rigid plastics. Even near its softening point, it often resists sudden impact better than brittle plastics like pure SAN. This makes it useful for parts that may face both heat and force.

Heat Resistance and Rigidity

ABS offers a balance of rigidity and heat resistance. The acrylonitrile and styrene components add stiffness and strength. At room temperature, ABS feels hard and solid.

As temperature rises, ABS gradually softens instead of instantly melting. It starts to flow well between about 220°C and 250°C.

During molding or 3D printing, if the heat is too low, ABS will not flow properly. If it is too high, the part may warp or lose detail. The correct heat keeps the shape stable and allows smooth flow.

Comparison with Other Plastics

Compared to SAN, ABS is less rigid but less brittle, making it more resistant to impact.

ABS has higher rigidity and a better surface finish than polyethylene or polypropylene, but those plastics melt at lower temperatures and are more flexible.

Choosing between materials? Dive into our article, PETG vs PLA: Which Filament Is Best for 3D Printing? to compare strength, heat resistance, and printability side by side.

Applications and Considerations for ABS Melting Point

Understanding the melting point of ABS (acrylonitrile butadiene styrene) is important before shaping or heating it. Its softening range affects molding, printing, machining, and real-world performance.

Industrial and Engineering Uses

ABS is used in car parts, tool housings, pipes, and plastic covers. It remains tough and strong while melting at a workable range, usually around 170°C to 230°C (338°F to 446°F).

In injection molding, ABS must be heated above its melt range to flow into the mold. Overheating can break down the plastic, while low heat prevents proper filling.

For 3D printing, the nozzle is often set between 220°C and 250°C, and a heated bed is used to reduce warping as the part cools.

- Good impact strength

- Moderate heat resistance

- Easy to machine after cooling

- Stable size when processed right

Controlling temperature is important to maintain these properties.

Choosing ABS Grades for Your Project

ABS grades vary. Manufacturers adjust the mix of acrylonitrile, butadiene, and styrene to change strength, flexibility, and heat resistance.

When picking a grade, check:

|

Factor |

Why It Matters |

|

Melt temperature |

Affects molding and printing settings |

|

Heat resistance |

Impacts use in warm spaces |

|

Impact strength |

Helps parts resist cracks |

|

Additives |

Change color, UV resistance, or flame rating |

If your part will face heat, choose a grade with higher heat resistance.

If you need easy shaping, pick a grade with a lower melt range.

Match the ABS melting point and properties to your machine settings and the final use of your product.

Wrap Up

Understanding ABS melting point helps you achieve stronger, cleaner prints and better molded parts. By controlling heat between 200°C and 240°C, you avoid warping, burning, and weak layers.

Whether you're 3D printing functional prototypes or injection molding durable components, knowing when ABS softens and flows gives you full control over your results.

Ready to experience the difference quality materials make? Try Siraya's premium filaments for consistent extrusion, reliable performance, and professional finishes. From heat-resistant blends to impact-tough formulations, Siraya delivers filaments engineered for real-world projects.Need help picking the right material? Check out our complete guide, 3D Filament Types: Complete Guide for Every 3D Project, to match filament properties with your project goals.

Frequently Asked Questions

What temperature does ABS plastic start to soften?

ABS starts to soften at about 95°C to 105°C, known as the glass transition temperature. At this point, the plastic becomes less stiff and more flexible, but does not fully melt.

At what temperature does ABS lose its structural integrity?

ABS loses much of its strength above 100°C and cannot hold heavy loads well. By around 120°C, it may bend or sag under stress and cannot keep its solid shape under pressure.

How high can ABS be heated before it deforms?

ABS can start to warp near 90°C to 100°C, especially if the part is thin. Above 105°C, it becomes soft enough to change shape. Around 200°C or more, it flows and can be molded or extruded.

What's the best heat setting for 3D printing with ABS?

Most 3D printers use a nozzle temperature between 220°C and 250°C for ABS. The heated bed should be set around 90°C to 110°C to reduce warping and keep the first layers flat.

Settings may vary depending on your printer and filament brand.

Can ABS withstand boiling water or does it warp?

Boiling water is 100°C, which is close to the softening point of ABS.

If you place ABS in boiling water, it can warp or bend, especially if the part is thin. Thick parts may keep their shape for a short time, but ABS is not suitable for long use in boiling water.

How does the melting point of ABS compare to other plastics?

ABS softens at a higher temperature than PLA, which softens around 55°C to 65°C.

It softens at a lower temperature than polycarbonate, which can handle heat above 140°C before softening.