説明

-

Extreme Heat Resistance (185°C HDT): Built for under-hood automotive, aerospace, and industrial parts.

-

Low Moisture Absorption: Warp-free, precise prints with excellent layer adhesion.

-

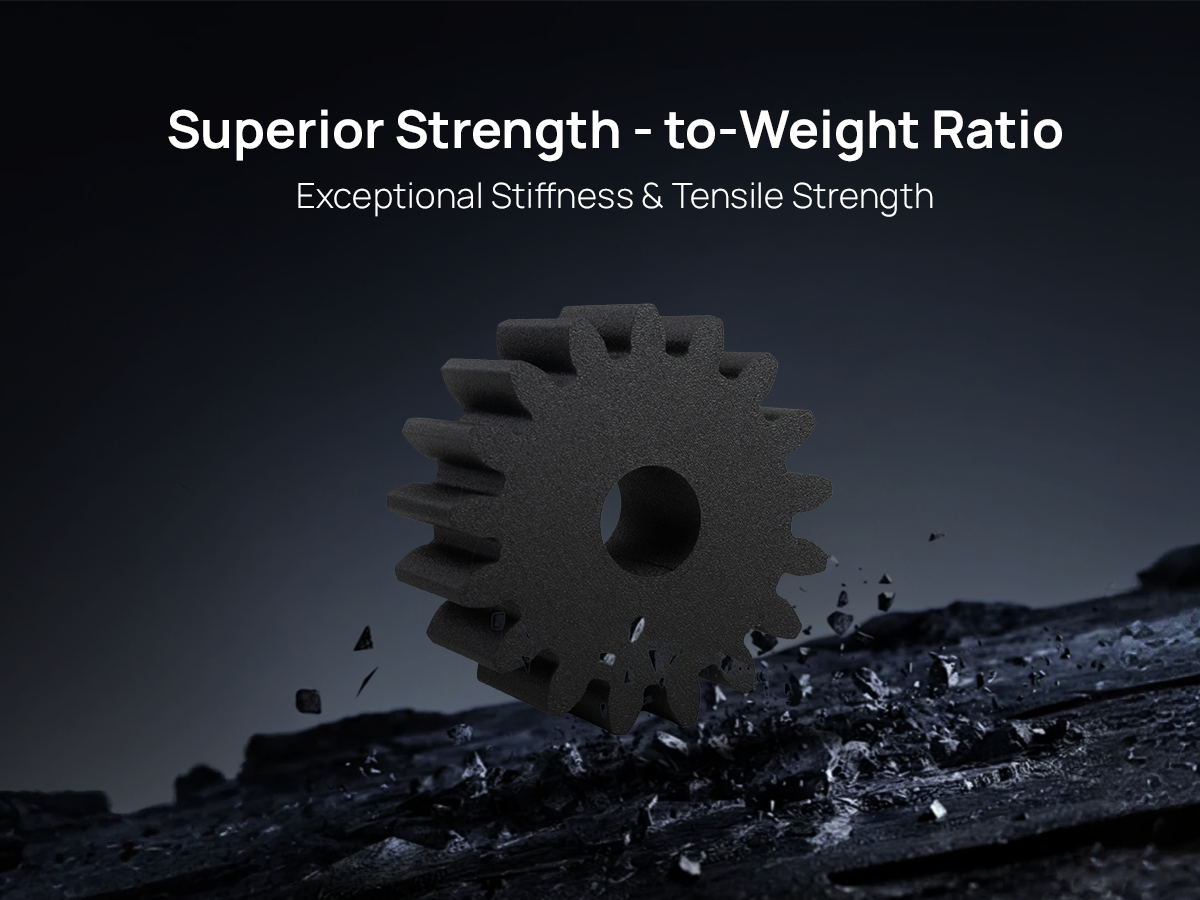

Industrial Durability: Superior strength, stiffness, and resistance to chemicals and oils.

-

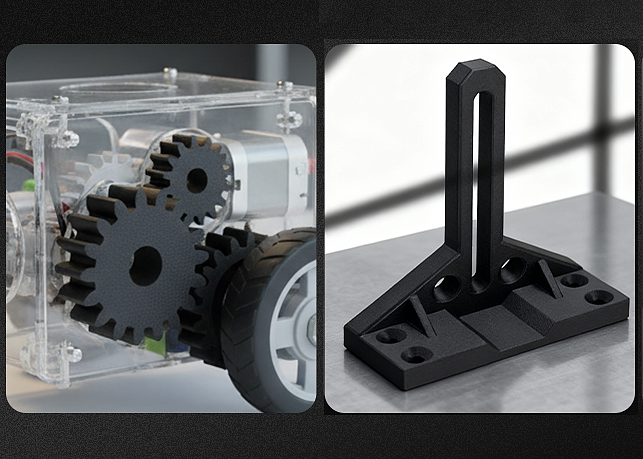

Lightweight Metal Replacement: Outstanding strength-to-weight ratio for functional, load-bearing components.

-

Engineered for Professionals: Optimized with 15% Glass Fiber Reinforced Technology for reliable flow and printability.

Why choose Fibreheart™ PPA-GF?

—— Meet needs from personal printing to professional manufacturing

Automotive

Aerospace & Drones

Industrial

Manufacturing

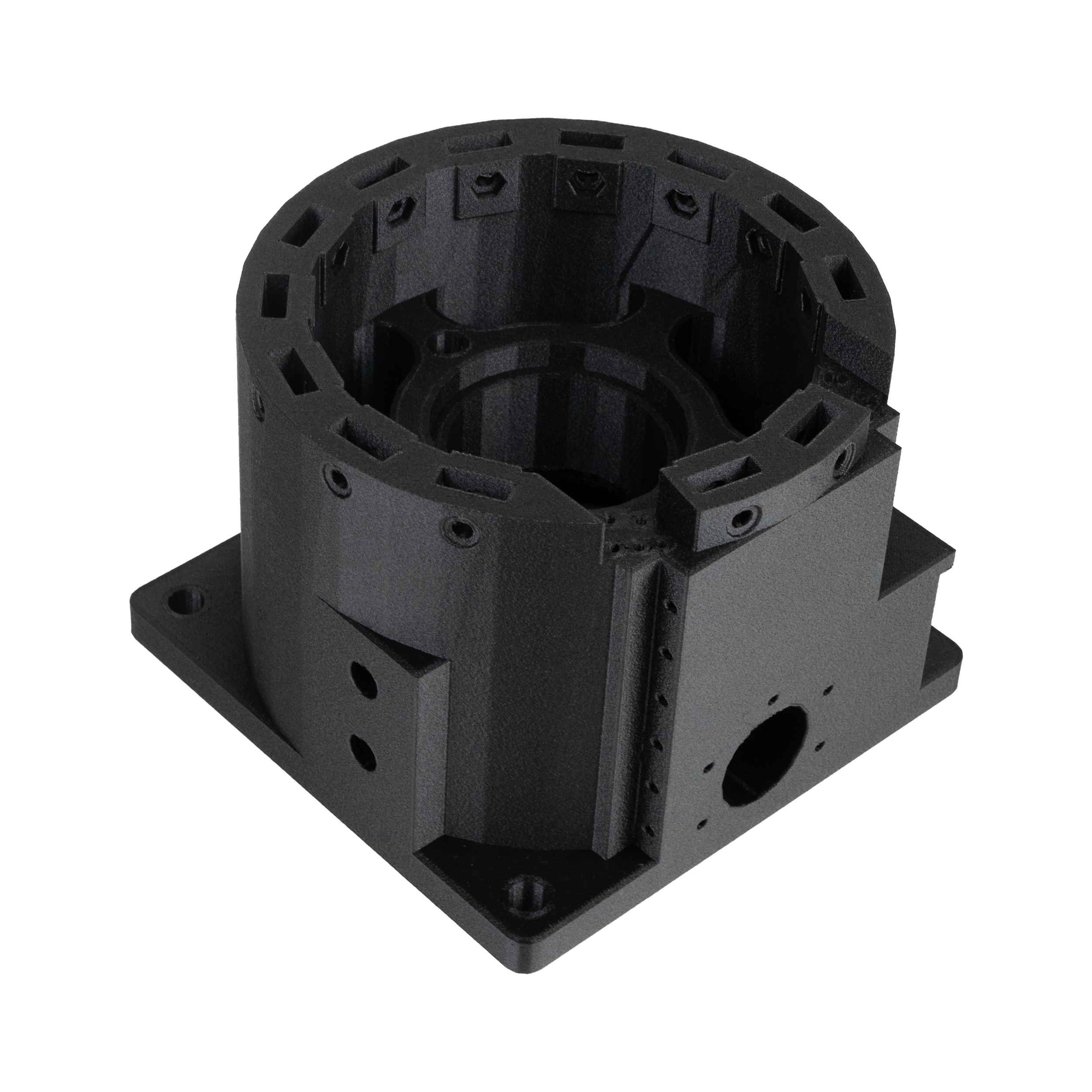

💪 High Strength & Rigidity

Reinforced with premium glass fibers for structural stability and excellent load support.

🔥Extreme Heat Resistance (185°C after annealing)

Maintains mechanical performance under high heat where ABS, PETG, and ASA fail.

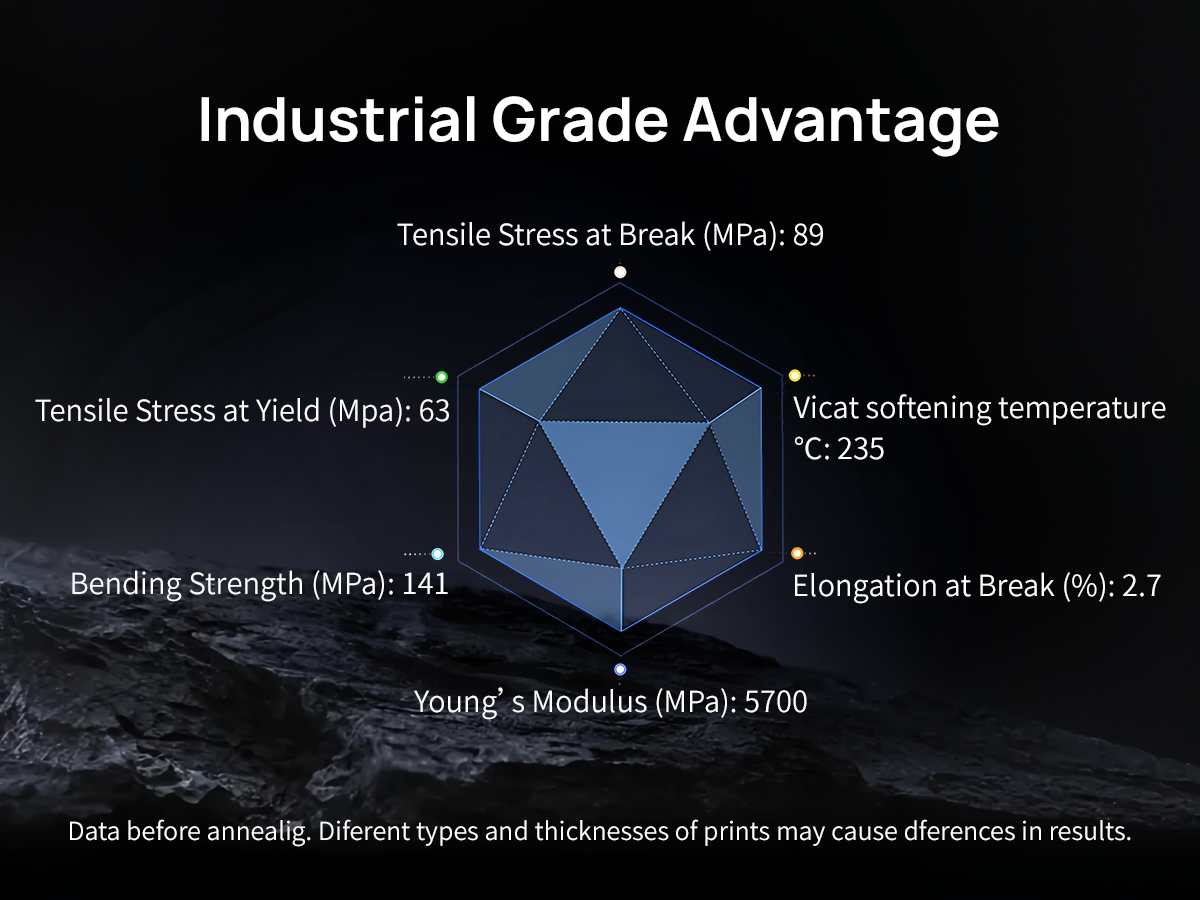

⚙️Industrial-Grade Performance

High-quality PPA nylon is combined with 15% glass fiber reinforcement to create a sturdy mesh structure for even greater rigidity!

💧 Low Moisture Absorption

Prints remain dimensionally stable — less warping, less shrinkage, and higher accuracy.

🧪Chemical Resistance

Withstands oils, fuels, and industrial fluids — perfect for automotive and mechanical applications.

🪶 High Strength-to-Weight Ratio

Ideal for automotive, aerospace, and drone components where every gram counts.

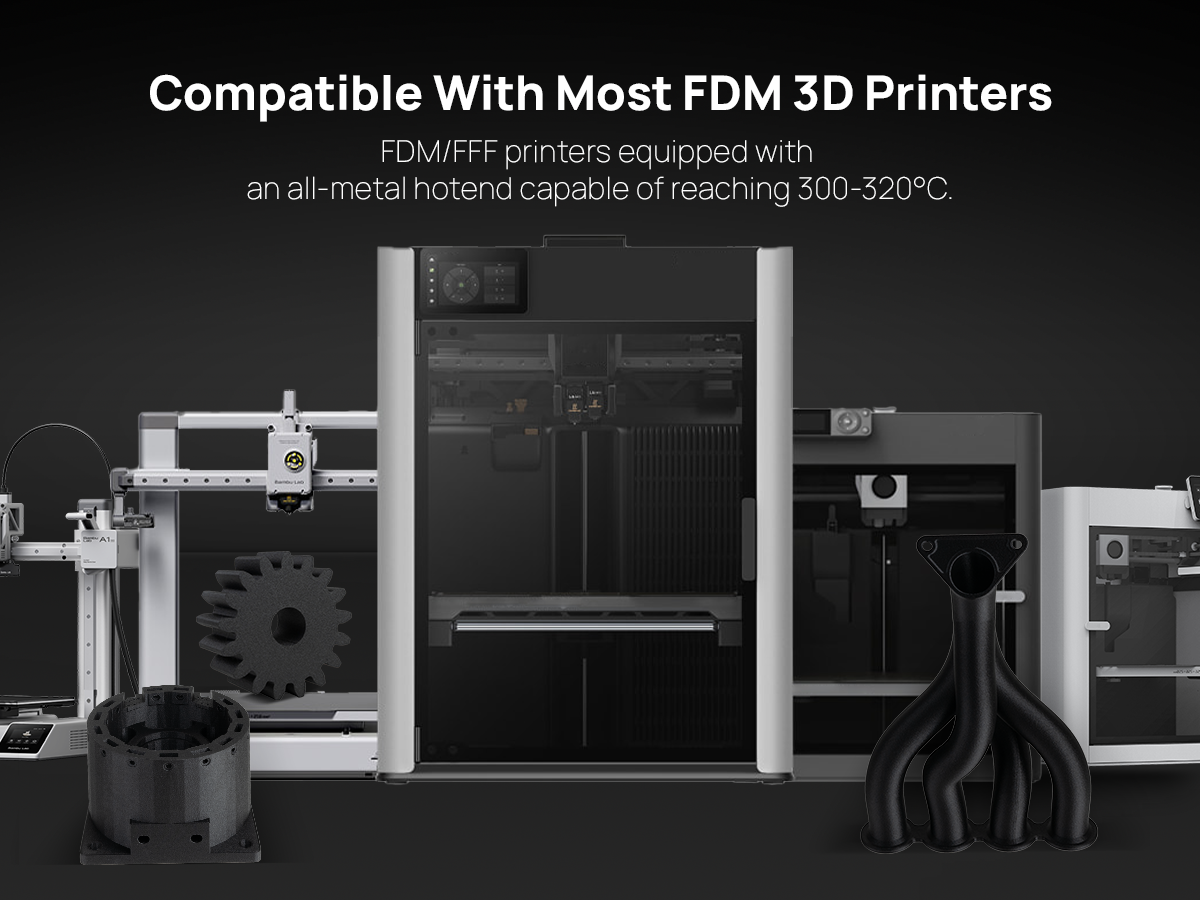

🧩 Easy to Print for an Engineering-Grade PPA Nylon

Optimized flow and adhesion make it easier to achieve reliable results on enclosed FDM printers.

Product Specifications

| Base Material | PPA Nylon + Glass Fiber |

| Diameter | 1.75 ± 0.3 mm |

| Net Weight | 1 kg |

| Packing size | 22*22*7 cm |

| Color | Black |

| Heat Deflection Temp (HDT) | 185°C |

User Manual

TDS

MSDS

Setting Profile

For other printers, please refer to the settings provided in the manual

Gallery

FAQ

For shipments to the United States, we ship from our US warehouse. For shipments to other countries, we ship from our overseas warehouse.

For specific shipping costs and shipping times, please refer to our shipping policy.

It absorbs far less moisture, has higher heat resistance, and delivers greater dimensional accuracy.

PPA and PA6 HDT are close when dry but PA6 gets wet and loses some HDT so in real world applications. PA6 is actually lower despite same level of HDT in ideal condition.

PA12 fare better in terms of water absorption but is not as robust as PA6 and thus PPA when dry and it still absorp water faster than PPA

For lightweight structural parts, yes. Its stiffness-to-weight ratio makes it a viable alternative in drones, automotive brackets, and jigs.