Recently viewed

PPA CF filament from Siraya is built for high-performance 3D printing where strength, heat resistance, and stability matter most.

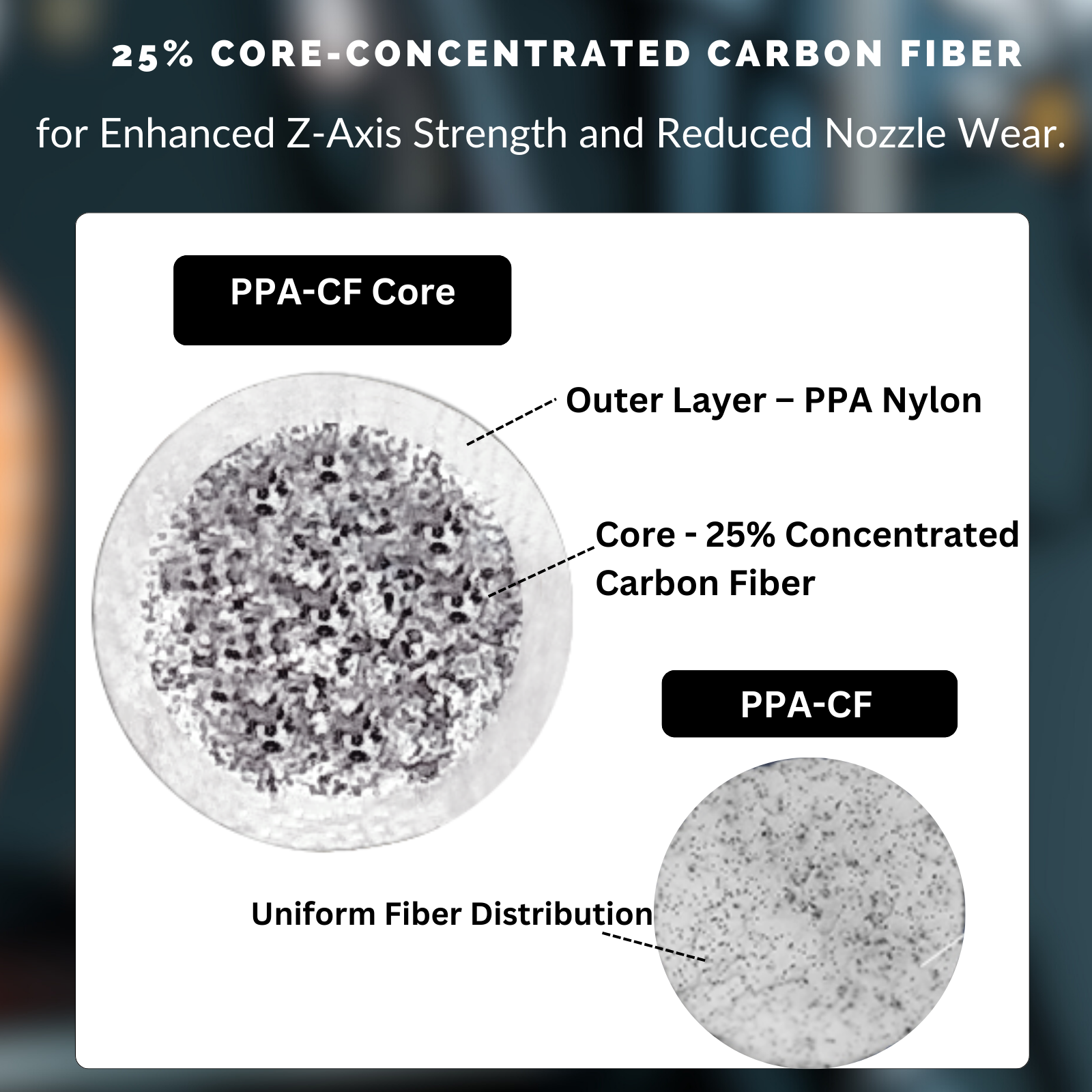

Made with a PPA (polyphthalamide) nylon base and reinforced with carbon fiber, these filaments deliver industrial-grade durability with reduced warping and low moisture absorption.

Our PPA CF blends make it possible to print parts that stay strong in demanding environments.

Print Parts That Stay Stable Under Heat and Stress

PPA CF filament is designed to handle high temperatures without losing strength or shape. It’s the go-to choice for functional parts that face real pressure.

Thermal Stability That Lasts

Unlike standard nylon, PPA CF maintains performance even in elevated temperatures. It’s ideal for automotive, aerospace, and mechanical parts.

- Heat deflection temperature up to 230°C

- Maintains stiffness under load

- Reliable for industrial-grade applications

Get Stronger Prints With Carbon Fiber Reinforcement

The carbon fiber blend boosts rigidity and reduces shrinkage. This means cleaner prints with less warping and higher dimensional accuracy.

Mechanical Strength You Can Count On

Carbon fiber reinforcement makes PPA CF tougher than unfilled nylon. It’s engineered for parts that need both strength and precision.

- High stiffness and tensile strength

- Reduced warping during long prints

- Lightweight with excellent strength-to-weight ratio

Keep Moisture Out for Consistent Results

PPA CF filament absorbs far less moisture than common nylons. That means fewer failed prints and more consistent performance.

Low Water Absorption for Better Storage and Printing

Parts stay dimensionally accurate even in humid environments. You spend less time drying filament and more time printing.

- Low moisture uptake compared to standard PA

- Improved shelf life and storage stability

- Reliable extrusion even in humid conditions

Print With Confidence on Advanced Machines

Siraya PPA CF filament is optimized for high-temperature FDM printers. It’s made for serious makers who want professional results at the desktop.

Engineered for High-Performance Printers

The filament works best with hardened nozzles and heated chambers, making it ready for advanced builds.

- Compatible with high-temp hotends

- Works with hardened steel or ruby nozzles

- Stable extrusion for long print jobs

Explore More From Siraya

If you’re exploring carbon fiber filament, check out these collections too:

- Engineering Resin – Flexible and impact-resistant resins for advanced projects.

- Fibreheart PPA Filament Family– High-performance nylon blends with toughness and heat resistance.

- Fibreheart ABS Filament Family– Durable ABS-based filaments designed for impact strength and stability.

- Flexible Resin Tenacious Family – Resins that add flexibility and impact resistance to your prints.

Frequently Asked Questions on PPA CF Filaments

What printer can print PPA-CF?

PPA-CF requires a 3D printer that can reach high nozzle temperatures, typically around 320°C, along with a heated bed and ideally a heated enclosure.

Because the filament is abrasive, a hardened steel or ruby-tipped nozzle is also necessary. Printers with these features can handle PPA-CF and produce strong, dimensionally stable parts.

Why is PPA-CF so expensive?

PPA-CF is more expensive because it combines an advanced polymer base with carbon fiber reinforcement, which requires specialized production.

The material offers high heat resistance, excellent strength, and reduced warping, making it suitable for demanding engineering applications. These performance benefits and the cost of manufacturing contribute to its higher price.

Does PPA-CF need annealing?

Yes, annealing PPA-CF is recommended to unlock its full mechanical strength and heat resistance.

After printing, parts can be annealed in an oven at around 80–100°C for several hours. This process improves dimensional accuracy, reduces internal stress, and enhances long-term durability.

Is PLA CF stronger than PLA?

Yes, PLA CF is stronger and more rigid than standard PLA. The carbon fibers increase tensile strength and reduce warping, giving prints better precision and durability.

While it is easier to print than other carbon fiber blends, it still requires a hardened nozzle due to the abrasive fibers.