When you get into 3D printing, filament safety is something you really need to think about. Melting plastic gives off fumes and tiny particles that can mess with air quality and your health.

The biggest worries? Toxic fumes, bad airflow, and handling hot or flammable stuff the wrong way.

Filaments like PLA are less risky because they don’t give off much, but ABS or Nylon can release nastier chemicals. Knowing what each filament does helps you pick the right one and keep your workspace safer.

Keep your area fresh with good airflow and wear protective gear when you print. Don’t skip safety steps—it’s just not worth the risk.

Key Takeaways

- Filament safety changes with the type of material and how you use it.

- Toxic fumes and bad ventilation are the main health problems.

- Smart habits and good gear make 3D printing a lot safer.

Start with ABS filament, which requires proper ventilation due to potential fumes during printing.

Major Health Risks of Filament Use

When you print, the heat and moving parts can send out tiny particles and gases. Breathing these in or getting them on your skin isn’t great, especially if you skip basic safety like ventilation or masks.

Ultrafine Particle Emissions

Melting filament releases ultrafine particles (UFPs)—they’re super tiny, under 100 nanometers, and hang around in the air for ages. You can end up breathing them deep into your lungs without noticing.

ABS, PLA, and nylon all give off UFPs, but the amount depends on the brand and temperature. The EPA says these particles can bother your eyes, nose, and throat, and if you breathe them in for a while, they might make asthma worse.

Want to cut down on UFPs?

- Print where air moves well.

- Use a HEPA filter or keep the printer in a closed box.

- Keep printers out of bedrooms or main living rooms.

Volatile Organic Compounds (VOCs) and Fumes

Hot plastic lets off volatile organic compounds (VOCs). These are gases that can make your throat or nose sting. You’ll find stuff like styrene and caprolactam in the mix.

ABS and ASA usually pump out more VOCs than PLA. Styrene, which comes from ABS, smells strong and can give you headaches or make you dizzy if you don’t have good airflow. The EPA says it might even cause cancer, so why risk it?

Here’s what helps:

- Open windows or use a vent fan right by the printer.

- Don’t run long prints in tiny, closed rooms.

- Look up the Safety Data Sheet (SDS) for your filament.

Respiratory and Skin Exposure

When you sand or cut prints, you kick up fine dust. This dust might have fibers, metal bits, or carbon, depending on your filament. It can bug your lungs or skin if you aren’t careful.

Put on a mask and goggles when you’re cleaning up or finishing prints. If your skin gets red or itchy, wear gloves and wash up after. Even PLA can bug your skin if you handle it a lot without gloves.

If you work with FDM filament, ensure your printer setup includes good airflow and temperature control.

Safety Concerns by Filament Type

Every filament is a little different. Some give off more fumes, some are trickier to handle. You’ve got to know what you’re dealing with before you start printing.

PLA (Polylactic Acid) Safety

PLA’s made from corn starch or sugarcane. People call it the “safe” filament because it melts at lower temps and doesn’t give off much.

Still, hot PLA releases a little bit of VOCs, so keep air moving or use an air filter. It’s not toxic, but sanding or grinding PLA can make fine dust, and you don’t want to breathe that in. Clean up with a damp rag, not a broom.

ABS (Acrylonitrile Butadiene Styrene) and Styrene Risks

ABS melts hotter and makes more fumes. Styrene is the big problem—it can give you headaches, make you feel sick, and irritate your eyes and throat if you breathe it in for too long.

Always print ABS in a box with a vent, or at least near an open window. A carbon filter in your air purifier helps catch the bad stuff.

If the plastic smell is strong, your room needs more airflow. Don’t print ABS in a closet or tiny office. Too much exposure can leave you dizzy or wiped out.

Polycarbonate and High-Temperature Filaments

Polycarbonate (PC) and other high-temp filaments like Nylon need hotter settings. If you overheat them, they can let off bisphenol A (BPA) and other chemicals.

Wear gloves when you touch these, since they can get sticky or break apart after printing. Keep them dry, because moisture makes them bubble and smoke more.

For PC, you really need a closed printer and good ventilation. The hotter you print, the more you need airflow.

Composite Filaments: Carbon Fiber and Metal Powders

Composite filaments mix in stuff like carbon fiber or metal powder. They’re tough, but sanding or cutting them sends out fine dust that’s rough on your lungs.

Use a dust mask or respirator, and vacuum with a HEPA filter. These filaments also chew up printer nozzles, so use a hardened steel nozzle. Keep your work area tidy so dust doesn’t spread everywhere.

For those using flexible filaments, handle with care to prevent clogging and overheating.

Environmental and Workspace Hazards

Your workspace really matters when you use filament printers. Heat, fumes, and stale air can cause health or fire problems if you don’t stay on top of things.

Ventilation and Air Quality

Good airflow clears out fumes and particles from hot filaments like ABS, PLA, or PETG. These give off ultrafine particles and VOCs when heated.

To keep the air clean, try these tips:

- Use a vent hood or local exhaust fan.

- Open windows or add HEPA and carbon filters.

- Put printers in rooms where air moves, not in a closet or tiny office.

Don’t stand right next to the printer while it’s running. Clean up dust and junk often so it doesn’t pile up.

Negatively Pressured Areas

A negatively pressured area keeps fumes from leaking into other rooms. Air comes in, but it can’t get out until it’s filtered or vented outside.

You can set this up with sealed boxes and exhaust fans that push air outdoors. This works well for busy places like schools, labs, or makerspaces where a bunch of printers run at once.

Seal doors and vents to keep the pressure right. Check airflow every so often to make sure it’s still working.

Fire and Explosion Risks

Filaments and printer parts get hot—sometimes really hot. ABS and a few others are more flammable. Overheating, bad wiring, or dust piles can all start a fire.

To stay safe, remember:

- Keep a Class C fire extinguisher close.

- Don’t leave printers running when you’re not around.

- Put printers on metal or ceramic, not wood or carpet.

- Store filaments away from anything hot.

Check cords, fans, and power supplies for damage. A clean, dry workspace makes fires less likely and helps you react fast if something goes wrong.

Read our article: Proper Handling of UV Curable 3D Printing Resins to understand best practices when working with sensitive materials.

Workplace Safety Practices

Lowering 3D printing risks means having clear rules, keeping records, and teaching good habits. A little planning and sticking to routines helps you dodge fumes, burns, and other problems from hot filament.

Administrative Controls

Keep Safety Data Sheets (SDS) for every filament and chemical. These tell you about hazards, how to handle stuff, and what to do if there’s an accident. Store them somewhere easy to grab.

Do a hazard check before printing. Look for spots where fumes or heat could be trouble. Use that info to decide if you need better airflow or a closed printer.

Keep track of equipment checks, filter swaps, and cleaning. Groups like NIOSH and the EPA say you should test air quality now and then for VOCs or fine particles.

Standard Operating Procedures

Write out simple, step-by-step guides for setting up, using, and shutting off printers. Post them by the machines where everyone can see.

Spell out safe distances, airflow needs, and how to deal with hot parts or waste. For example:

|

Task |

Key Safety Step |

|

Loading filament |

Wear gloves to avoid burns |

|

Printing |

Keep covers closed |

|

Cleaning |

Use mild cleaners, not solvents |

Update your safety steps when you get new materials or gear. When everyone follows the same routine, it’s easier to catch unsafe habits early.

Training and Awareness

Train everyone who uses or hangs out near the printers. Explain what fumes, particles, and burns can do. Show how to use gloves, goggles, and masks.

Give quick refreshers when you get new filaments or machines. Share safety tips from NIOSH or manufacturers.

Tell people to speak up if they smell something weird, get a headache, or see smoke. When everyone knows what to look for, you can fix little problems before they get big.

Learn about safe storage and cleaning in our guide on Cleaning and Sterilizing Siraya Tech Defiant Silicone Parts.

Protective Measures and Equipment

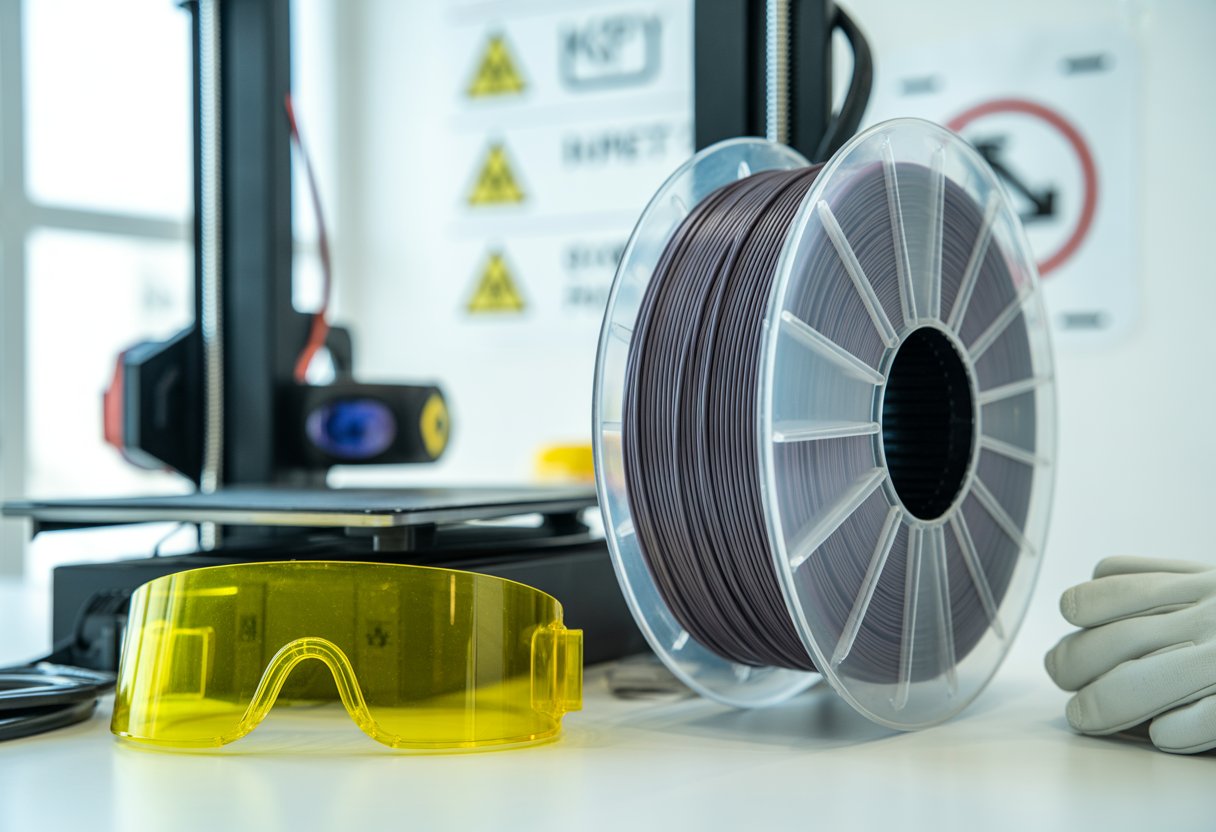

You can stay safer while working with filament if you wear the right gear and use good ventilation. Handle chemicals with care too.

These steps help lower your risk of breathing fumes, getting burns, or touching unsafe stuff.

Personal Protective Equipment (PPE)

Always wear PPE when you 3D print. Grab some safety glasses or goggles to shield your eyes from flying bits of filament.

Put on heat‑resistant gloves so you don’t burn your hands on hot printer parts. Long sleeves and closed‑toe shoes protect your skin from melted plastic or sharp edges.

When you trim or sand prints, cut‑resistant gloves help you avoid cuts. It’s smart to keep a small table or shelf with your PPE nearby.

|

Task |

Recommended PPE |

|

Printing |

Safety glasses, gloves |

|

Cleaning or sanding |

Dust mask, gloves |

|

Handling hot parts |

Heat‑resistant gloves |

Check your gear for cracks or tears. Swap it out if it looks worn.

Respiratory Protection

3D printing can put ultrafine particles (UFPs) and volatile organic compounds (VOCs) into the air. Try to print in a well‑ventilated area or set up a local exhaust system near your machine.

If you can’t boost ventilation, use a NIOSH‑approved respirator with filters for small particles and fumes. A P100 or N95 mask blocks most airborne stuff.

Keep your printer’s enclosure closed while it runs. Open it only when you need to.

Clean filters and fans often so airflow stays strong and safe.

Safe Handling of Solvents and Chemicals

Some filaments, like ABS or resin, need solvents for cleaning or smoothing. Use these chemicals in a space with good airflow and far from flames or sparks.

Wear chemical‑resistant gloves and eye protection to keep splashes off your skin and eyes. Store solvents in labeled, sealed containers away from kids and pets.

Don’t mix different cleaning solutions—bad things can happen, like harmful gases. Dispose of used solvents the right way for your area, not down the drain.

For a broader perspective, check out our article on Injection Molding vs 3D Printing: Which Is Better? and What is ABS Filament? Uses, Pros, and Cons for 3D Printing.

Post-Processing and Maintenance Safety

You face the most risk after printing when you trim, sand, or clean your 3D prints. Small particles, fumes, and sharp tools can hurt you if you skip basic safety steps.

Handling Filament Waste

When you remove supports or failed prints, tiny plastic bits and dust can go everywhere. Wear gloves and a dust mask to keep particles off your skin and out of your lungs.

Drop scraps in a small bin or sealed bag. Don’t throw melted or mixed filament in the regular trash—it might give off fumes or stick to other garbage.

If you use SLA or DLP resin prints, cure leftover resin before you toss it. Uncured resin can irritate your skin and pollute water. Label and store waste until you can take it to a recycling or hazardous waste center.

|

Material Type |

Safe Disposal Tip |

|

PLA |

Can go in plastic recycling if clean |

|

ABS |

Bag and seal before trash |

|

Resin |

Cure fully before disposal |

Cleaning and Maintenance Hazards

You need to clean nozzles, build plates, and fans to keep prints smooth. Wait for the printer to cool and use non-flammable cleaners to avoid burns or skin irritation.

Don’t blow dust with compressed air—it just spreads fine particles. Wipe surfaces with a damp cloth or use a vacuum with a HEPA filter instead.

When you use alcohol or acetone to clean, crack open a window or run a fan. Store cleaning liquids away from heat, and unplug the printer before you wipe near wires or motors.

Final Thoughts

Understanding what safety concerns for a filament exist is essential for safe and responsible 3D printing.

From fumes to handling temperatures, each material has unique safety needs. Proper ventilation, protective gear, and correct storage can prevent health risks and equipment damage. Being informed helps you print smarter and safer.

For reliable, low-odor, and high-quality materials that meet safety standards, explore Siraya.Tech filaments — engineered for performance, consistency, and peace of mind in every print.

Frequently Asked Questions

What should I look out for to avoid fire hazards with 3D printers?

Put your printer on a flat, non-flammable surface. Make sure wires and power cords aren’t frayed or damaged.

Don’t leave the printer running when you’re not around. Try to use printers with thermal runaway protection to stop overheating.

Can using a 3D printer indoors affect my health?

Yeah, it can. Some filaments let off tiny particles and fumes when you heat them.

Print in a room with good airflow or near an open window. A fume hood or air filter helps you breathe easier.

What's the safety checklist I should follow when 3D printing?

- Check cables, fans, and nozzles before you print.

- Keep your printer clean and dust-free.

- Wear gloves and safety glasses when you handle hot or melted material.

- Always have a fire extinguisher nearby, just in case.

Are there any health risks associated with 3D printer emissions?

Yep. Heated plastics like ABS and Nylon give off fumes that can bug your eyes, nose, or throat.

PLA is a bit safer but still releases small particles. Keep your space ventilated and don’t breathe right next to the printer while it runs.

How do I conduct a risk assessment for my 3D printing workspace?

Look at where your printer sits, how air moves in your room, and what materials you use.

Check for fire risks, electrical issues, and bad airflow. Write down what you find and fix any problems before you print again.

Is it true that PLA material can be dangerous when 3D printing?

PLA is one of the safer filaments. It comes from plant-based stuff, which is kind of cool.

But when you melt it, you might notice some mild fumes. Keep fresh air moving in the room, and don’t touch the hot nozzle or filament—trust me, it hurts.