Description

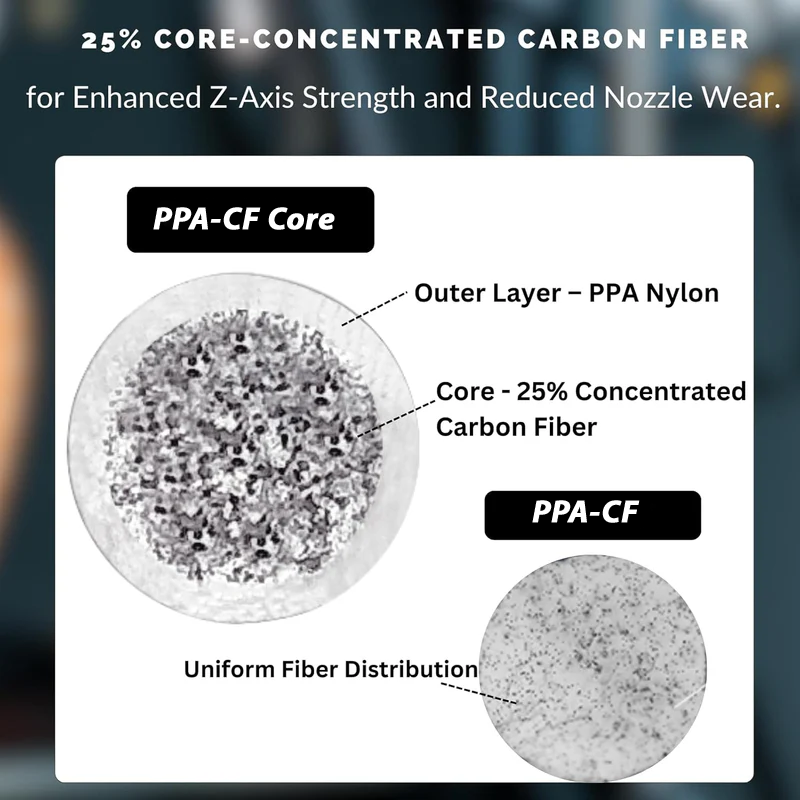

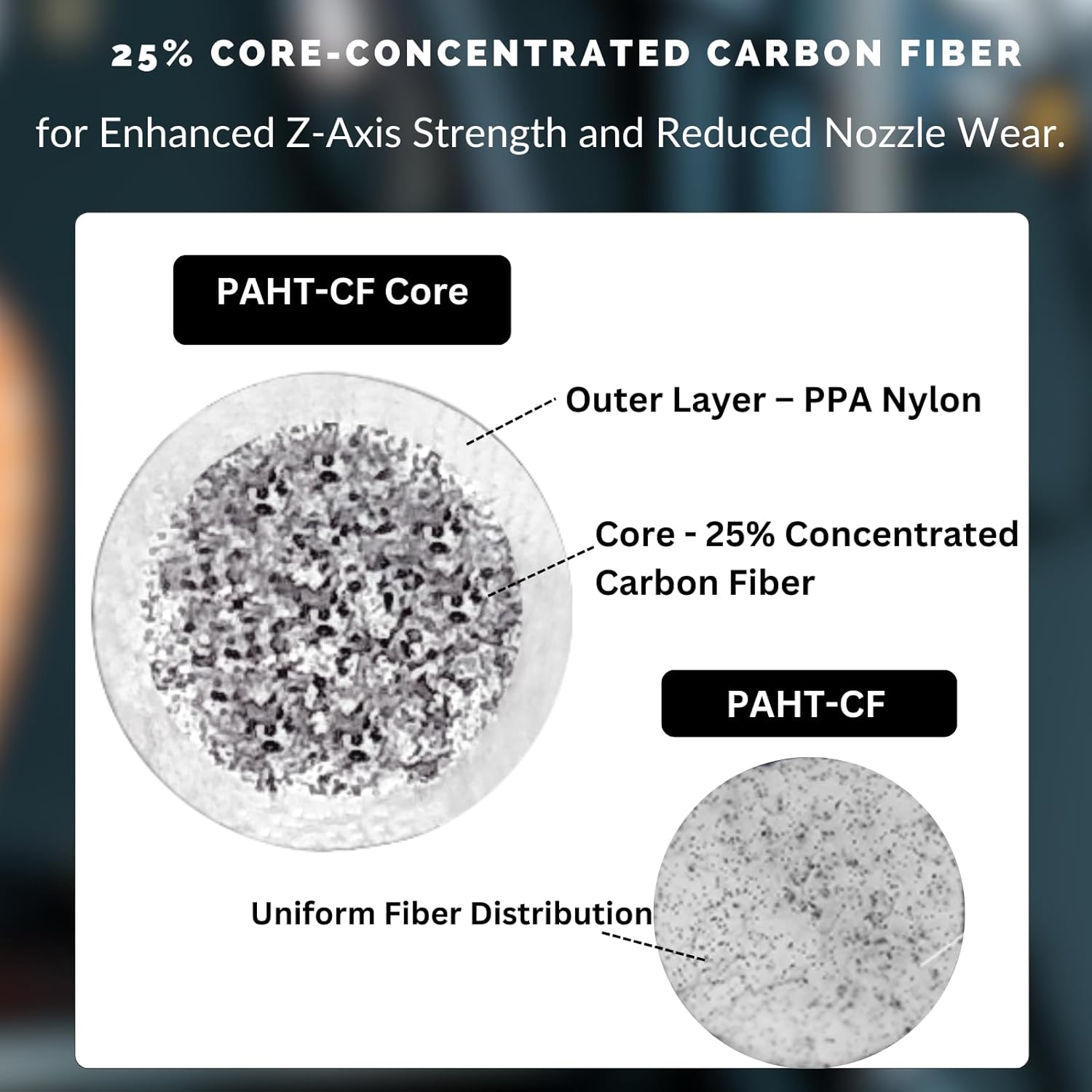

Revolutionary Core-Shell Structure

- Optimized Fiber Distribution: 25% carbon fiber concentrated in the filament core

- Enhanced Layer Adhesion: PPA outer shell ensures superior Z-axis bonding

- Reduced Nozzle Wear: Protective outer layer minimizes abrasive fiber contact with printer components

Performance Benefits

- High Strength & Stiffness: 25% fiber content for enhanced mechanical properties.

- Superior Layer Bonding: Pure PPA shell-to-shell contact boosts Z-axis strength.

- Dimensional Stability: Core-shell structure minimizes warping, ensuring part accuracy.

-

Extended Equipment Life: Reduced wear on nozzles and extruders Carbon Fiber.

Skin-Friendly: Outer shell design minimizes skin irritation.

Why choose Siraya Tech Fibreheart PPA-CF Core

Revolutionary Carbon Fiber Core Technology

- With 25% core-shell carbon fiber

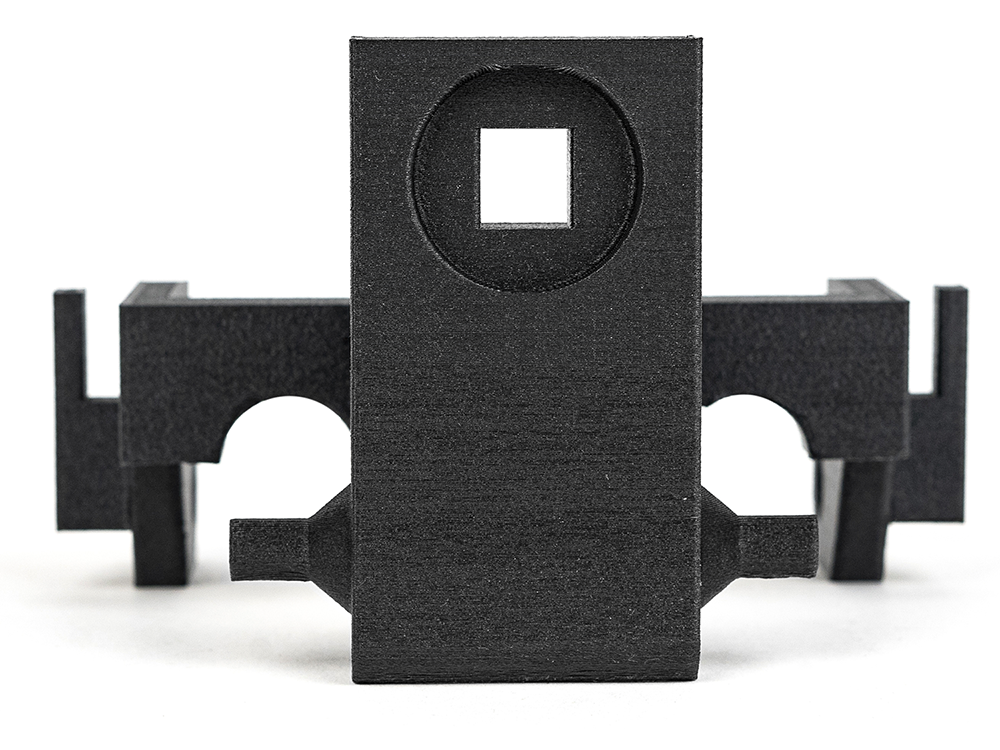

With a 25% core-concentrated carbon fiber design, PAHT-CF Core Black achieves exceptional stiffness, lightweight durability, and impressive Z-axis strength, making it ideal for high-performance parts that demand superior structural integrity.

High-Performance PPA Nylon Base

Built with advanced Polyphthalamide (PPA) Nylon, PAHT-CF Core filament delivers outstanding strength, chemical resistance, and thermal stability. It maintains low moisture absorption, ensuring reduced warpage and consistent results in any environment.

Engineered for Extreme Heat and Stress

Perfect for automotive and industrial applications, this filament retains its strength and shape under high temperatures, offering excellent abrasion resistance and dimensional stability in challenging conditions.

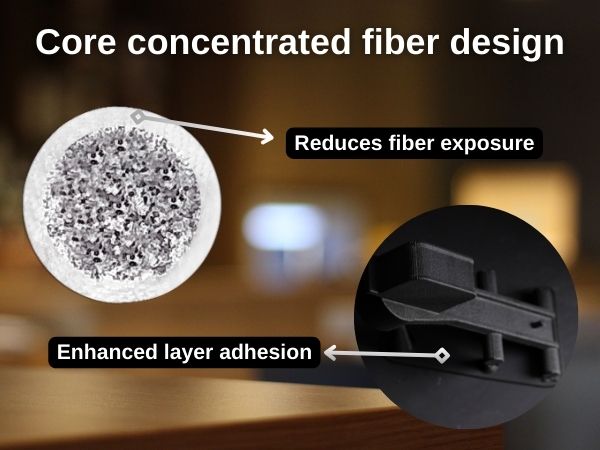

Enhanced Printability and Safety

The core-concentrated fiber design reduces wear on nozzles and enhances layer adhesion, leading to high-quality prints.

It also minimizes fiber exposure, making handling safer for users (PU gloves recommended).

Versatile Application Potential

From automotive and aerospace to industrial tooling and consumer goods, PAHT-CF Core Black is ideal for creating lightweight, heat-resistant, and durable components, making it the top choice for engineers and makers in demanding applications.

Customized aluminum bag packaging, more water-resistant

Use customized higher-grade and thicker aluminum tape for vacuum packaging.

Aluminum bags have lower water vapor permeability and can better maintain filament performance.

Saving your time: It can be printed directly without drying after arrival!

PAHT-CF Core is dried and sealed into aluminum bags, and can be printed directly without having to be dried again after the first delivery.

(Unless the filament appears to have absorbed water obviously!)

Print with Siraya Tech Fibreheart PAHT-CF Core

Printing Requirements and Post-Processing

- Nozzle: Hardened steel or higher grade;

- Nozzle Diameter: 0.4-1.0mm;

- Bed Surface: PEI with Glue Stick or PVP glue coating

Annealing Guidelines (Optional)

- Temperature: 80-100°C

- Duration: 4-8 hours

- Cooling: Allow natural cooling to room temperature

Optimal Printing Parameters

Nozzle Temperature: 280-320°C

Bed Temperature: 80°C

Cooling Fans: OFF

Print Speed: 30-120 mm/s

Layer Height: 0.2mm (recommended)

Retraction Distance: 1-3mm

Retraction Speed: 1800-3600 mm/min

Raft Separation: 0.08-0.12mm

Support Material: Compatible with quick-release support materials

FAQ

Please be aware that using CHT-style multipath nozzles with Fibreheart PPA-CF Core may result in a significantly rougher print surface.

The unique design of these nozzles disrupts and redistributes the carbon fiber core within the filament, leading to dispersed fibers and a compromised surface finish.

For optimal print quality, we recommend using standard hardened steel nozzles with a 0.4mm or larger opening.

✅ A high-temperature 3D printer is recommended (Nozzle: 280-300°C, Bed: 100-120°C).

✅ An all-metal hot end is required to withstand high printing temperatures.

✅ An enclosed printer is recommended to maintain stable temperatures and reduce warping.

✅ A hardened steel or higher grade nozzle (minimum 0.4mm) is recommended to reduce wear and maintain print quality.

❌ Do not use brass nozzles, as the carbon fiber content will wear them down quickly.

📌 Store in a dry box with relative humidity below 15%

📌 Promptly reseal packaging after use.

Dry filament at 100-120°C for 4-6 hours to restore print quality.

❌ No, it is not compatible. The high carbon fiber content makes PPA-CF Core brittle, and it may break in AMS’s long and tightly curved feed tubes, leading to feeding issues or print failures. We recommend using direct drive or a short-path extrusion system for the best printing performance.