Description

Available on Amazon

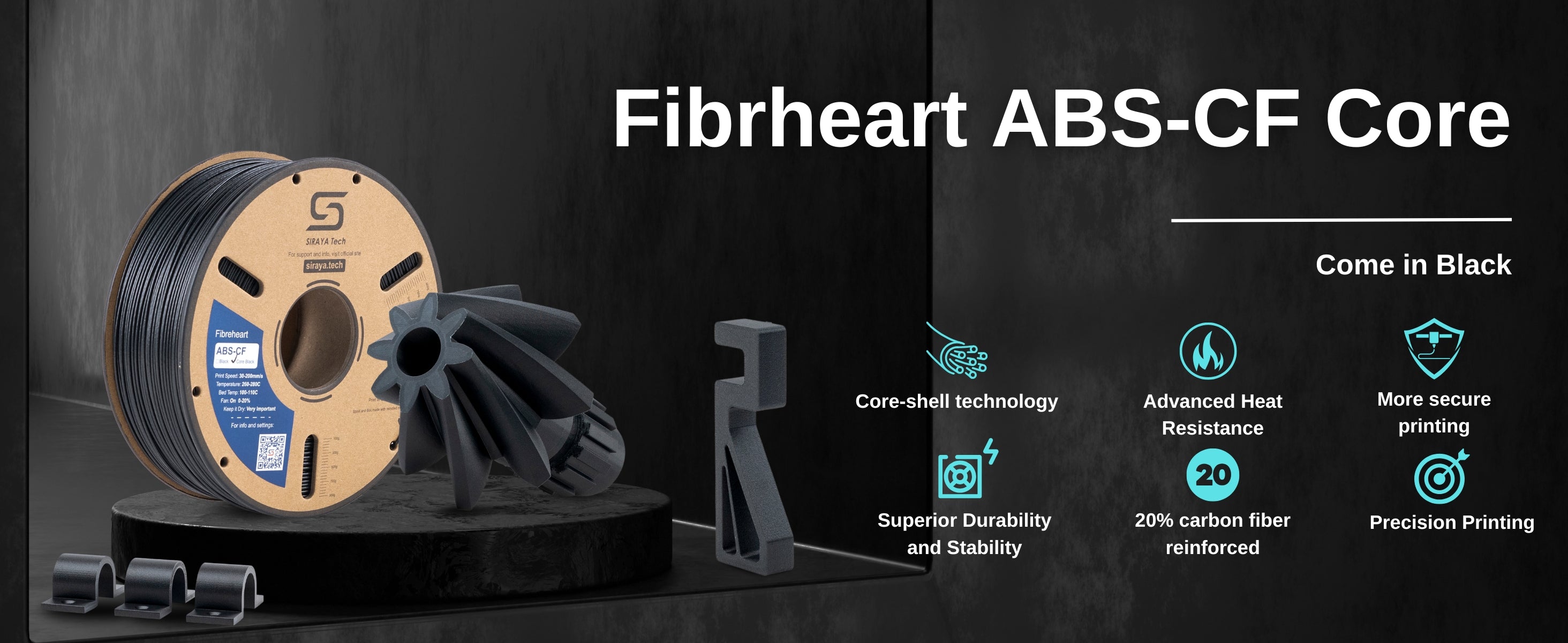

Key Feature:

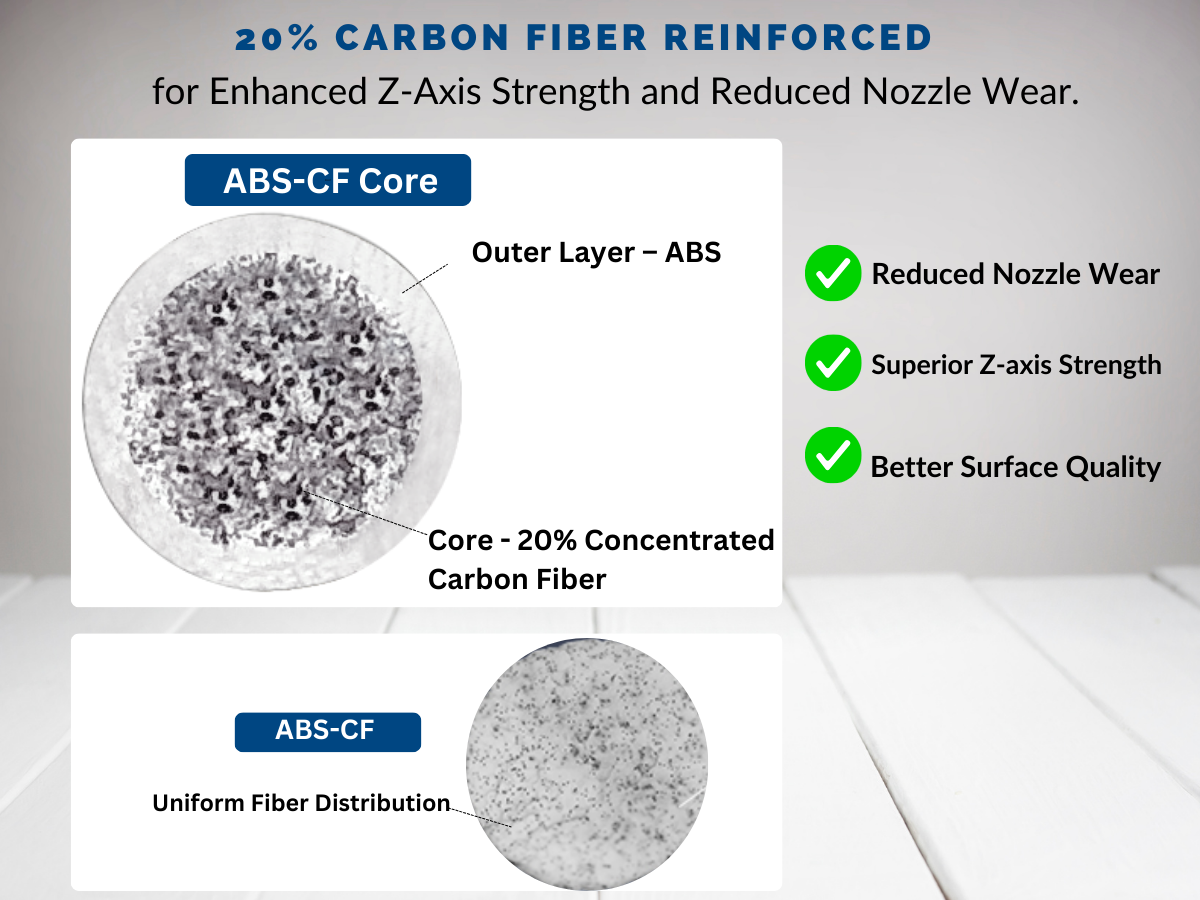

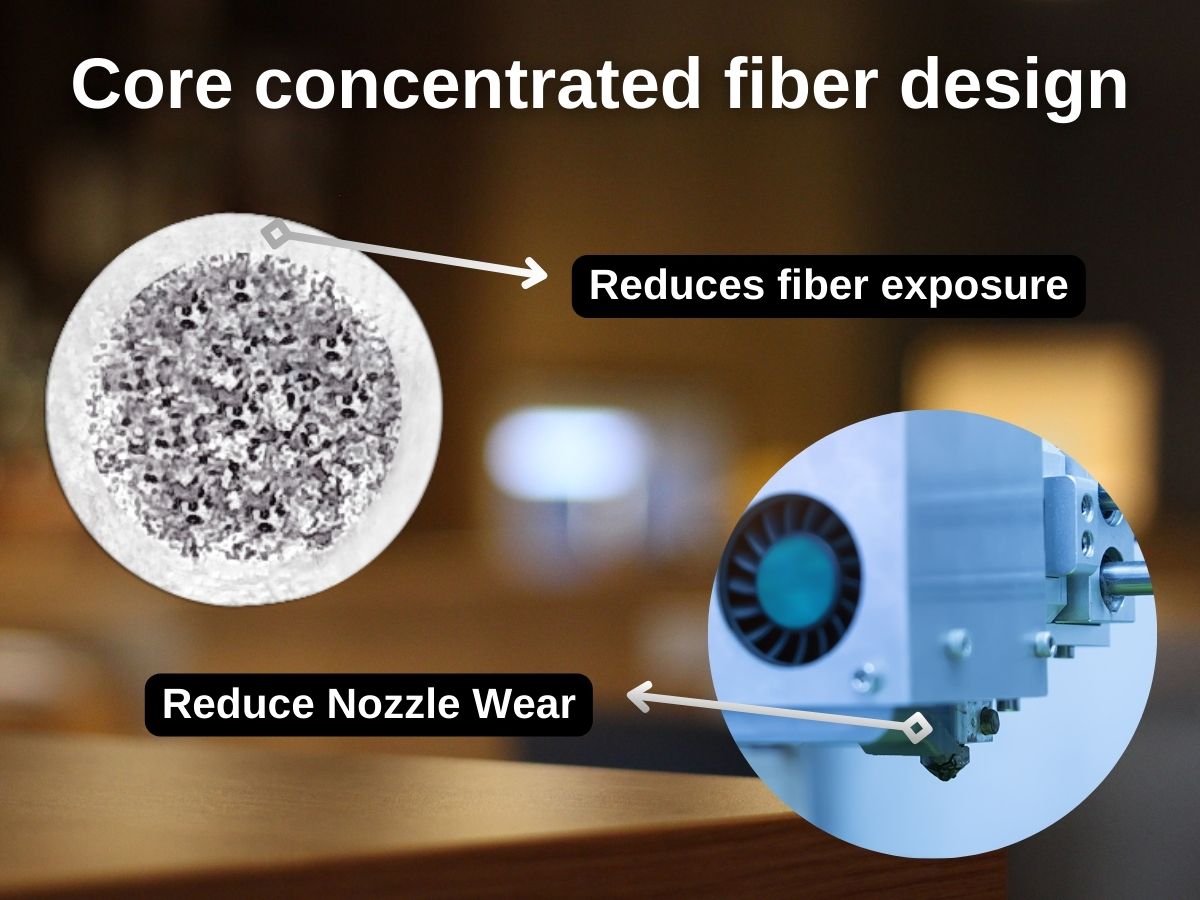

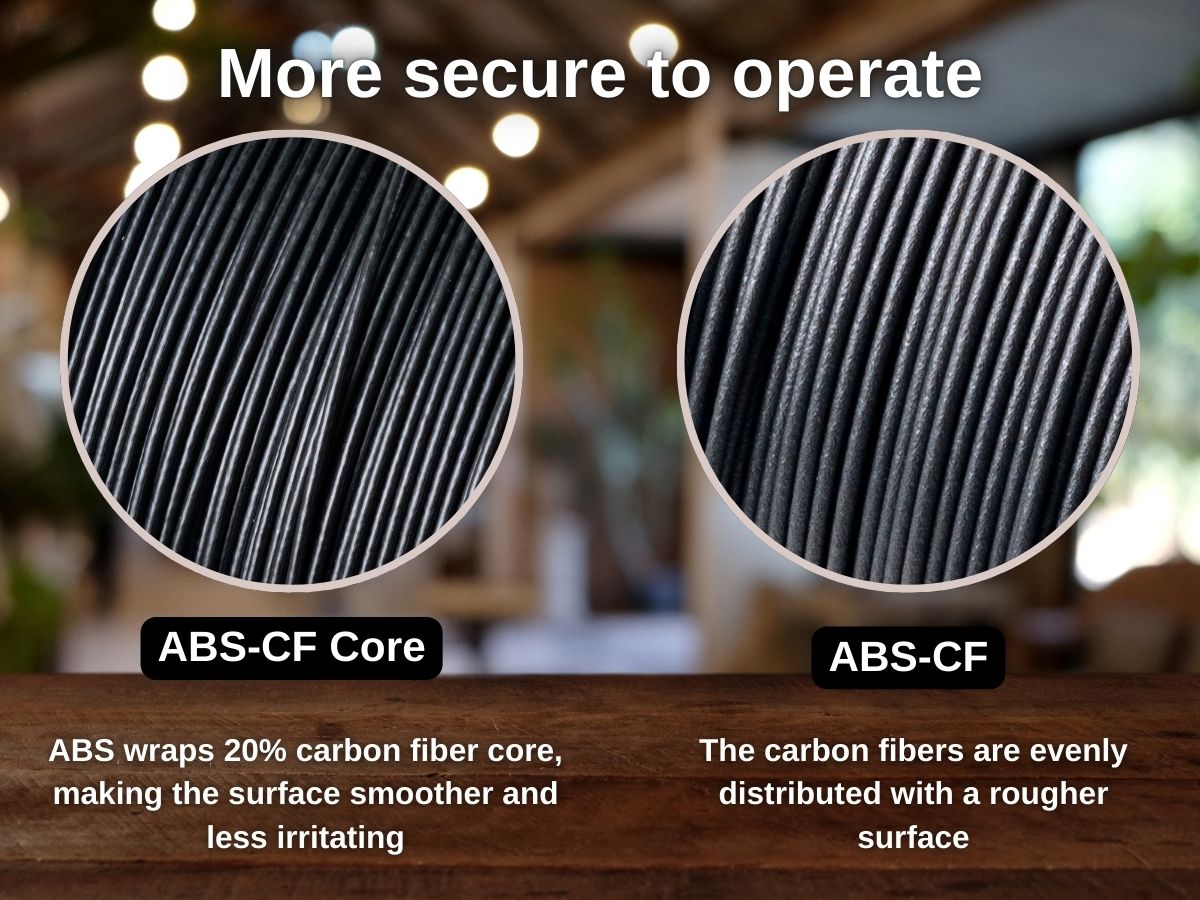

- Enhanced Strength: 20% core-concentrated carbon fiber for superior rigidity.

- Stronger Layer Adhesion: Improved Z-axis strength and bonding.

- Reduced Nozzle Wear: Less fiber contact extends nozzle life.

- Heat Resistance: Withstands up to 90°C for high-temp applications.

- Safer, Cleaner Printing: Lower VOCs and reduced fiber exposure.

Applications:

- Aerospace: Lightweight, durable components for drones and UAVs.

- Automotive: Heat-resistant parts for under-hood applications.

- Industrial: Long-lasting tooling and jigs for heavy-duty use.

- Robotics: Precision, load-bearing parts for advanced robotics.

- Engineering: High-strength prototypes for rigorous testing.

Why choose Siraya Tech Fibreheart ABS-CF Core

Revolutionary Core-Strength Design

With 20% carbon fiber reinforcement concentrated in the core, this filament delivers exceptional rigidity and structural integrity without sacrificing print quality or surface smoothness.

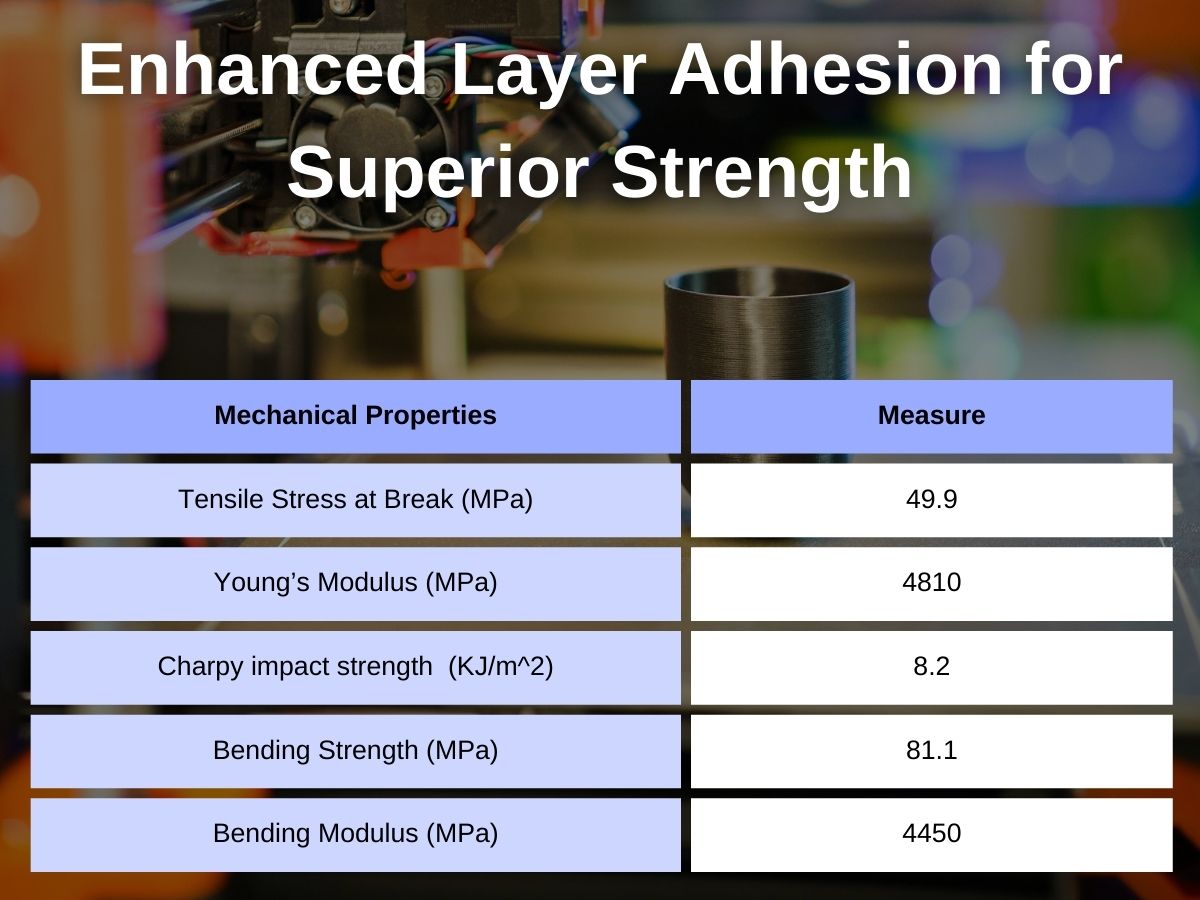

Enhanced Layer Adhesion for Superior Strength

Enjoy improved layer bonding, leading to outstanding strength and part durability, perfect for applications requiring robust, reliable mechanical properties.

Precision Printing at High Speeds

The unique core structure allows high-speed printing up to 200 mm/s with consistent quality, enabling efficient production without compromising detail or strength.

Extended Nozzle Life with Minimal Wear

The innovative design reduces direct contact between fibers and the nozzle, prolonging component life and minimizing maintenance, especially when used with wear-resistant nozzles.

Heat Resilience for Demanding Applications

With a heat deflection temperature of 90°C, this filament is ideal for high-temperature, industrial, and engineering applications where durability is critical.

Safer Handling

With fewer fibers on the surface, there's reduced risk of skin irritation. However, we still recommend using PU gloves when handling printed parts for maximum safety.

Applications

ABS-CF Core Black filament offers 20% carbon fiber for superior strength and stiffness, ideal for aerospace, automotive, and industrial parts. Its core structure improves layer adhesion, reduces nozzle wear, and ensures durability, making it perfect for high-precision, long-lasting applications.

How to print Siraya Tech Fibreheart ABS-CF Core

Optimal Printing Parameters

Nozzle temperature: 250-280°C

Build plate temperature: 100-110°C

Print Speed: 30-200 mm/

Recommended nozzle diameter: 0.4-1.0 mm

Nozzles Material: Hardened steel

Minimum heating block thickness: 12mm

Retraction distance: 1-3 mm

Retraction speed: 1800-3600 mm/min

Build Platform Material: PEI film is recommended and with optional Glue Stick or PVP glue coating for enhanced adhesion

Cooling Fan: Run at 0-20% speed

Note that very high speeds may affect the core-shell structure. If surface quality degrades, either increase temperature or reduce speed.

Moisture Management

Carbon fiber reinforced ABS filaments are susceptible to moisture absorption, which can affect print quality.

(1) Storage

Store the filament in its original moisture-resistant packaging when not in use. Using a dry box with desiccant is recommended for prolonged storage.

(2) Drying Filament

ABS-CF Core is packaged in waterproof aluminum and already dried before sealing, so it can be printed directly after the package is opened for the first time.

If print quality degradation is observed (bubbles, stringing), dry the filament at 60-70°C for 4-6 hours before printing. Only dry if the filament is damp.

FAQ

Please be aware that using CHT-style multipath nozzles with Fibreheart ABS-CF Core may result in a significantly rougher print surface. The unique design of these nozzles disrupts and redistributes the carbon fiber core within the filament, leading to dispersed fibers and a compromised surface finish. For optimal print quality, we recommend using standard hardened steel nozzles with a 0.4mm or larger opening.

To print with ABS-CF Core filament, your 3D printer should have:

- A nozzle temperature of 250-280°C

- A heated bed capable of reaching 100-110°C

- A PEI sheet or PVP glue stick for optimal bed adhesion

- An enclosure to improve layer bonding and minimize warping

- A hardened steel or wear-resistant nozzle to handle carbon fiber reinforcement

Since ABS-CF Core contains 20% carbon fiber, it is highly abrasive and can wear out standard brass nozzles quickly. We strongly recommend using:

- Hardened steel nozzles with 0.4mm or larger

- Rubidium or tungsten carbide nozzles for extended lifespan

- Nozzles with at least 0.6mm diameter if printing at high speeds to avoid clogging

We don’t recommend it.

Carbon fiber makes the filament more brittle, and it can break inside the AMS feed path, leading to jams or failed prints.

For best results, use a direct-drive extruder or load the filament manually.