Description

Fibreheart TPU-GF: Engineering Grade Toughness, Zero Frustration.

Stop choosing between stiffness and brittleness. Fibreheart TPU-GF is the ultimate "Stiff-but-Elastic" composite, designed for high-impact functional parts that standard PLA-GF or Nylon-GF simply can’t handle. Featuring ultra-low warp and exceptional vibration damping.

- The End of Brittle Failures: Ultimate impact insurance for functional parts.

- Professional Vibration Isolation: Smoother FPV footage and reduced mechanical stress.

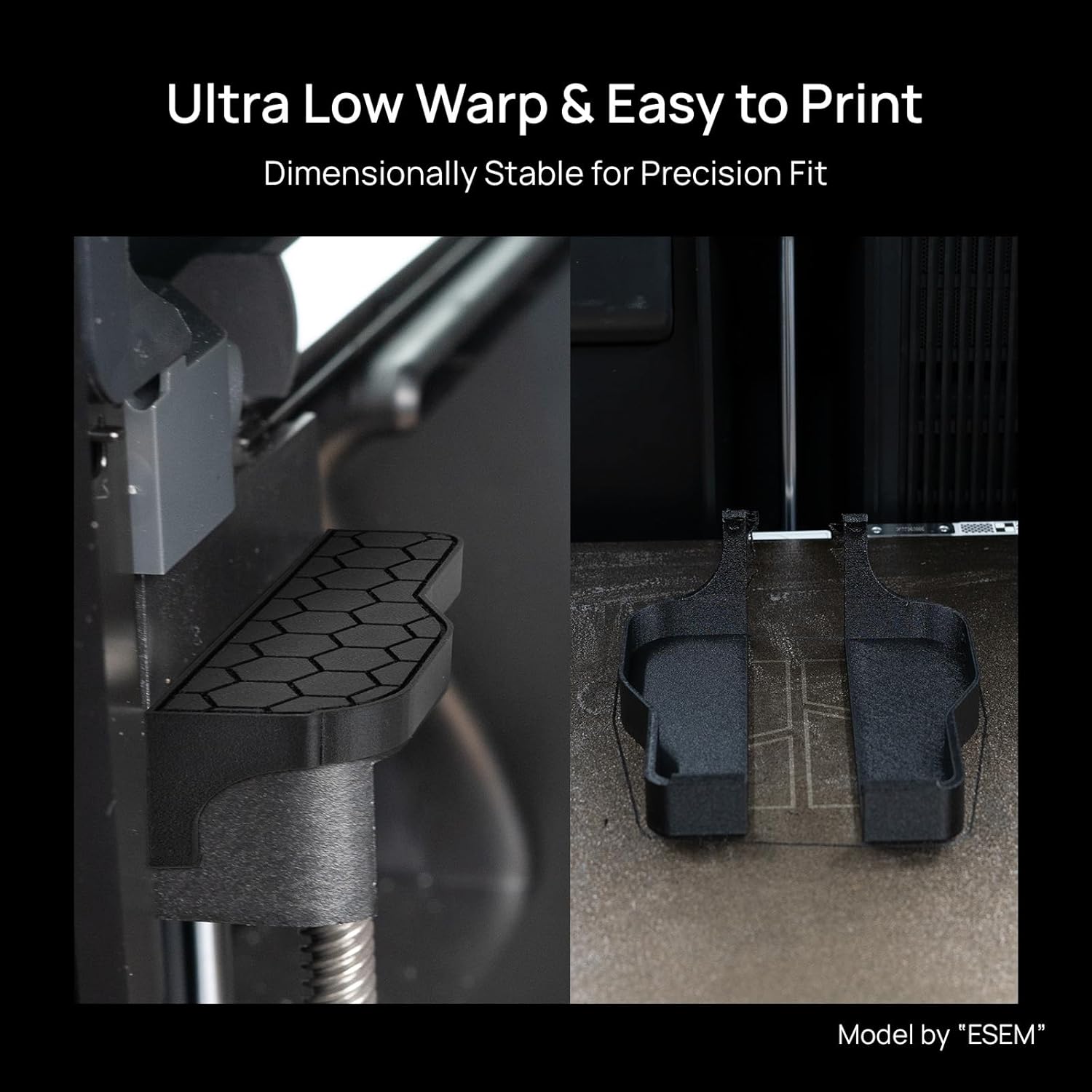

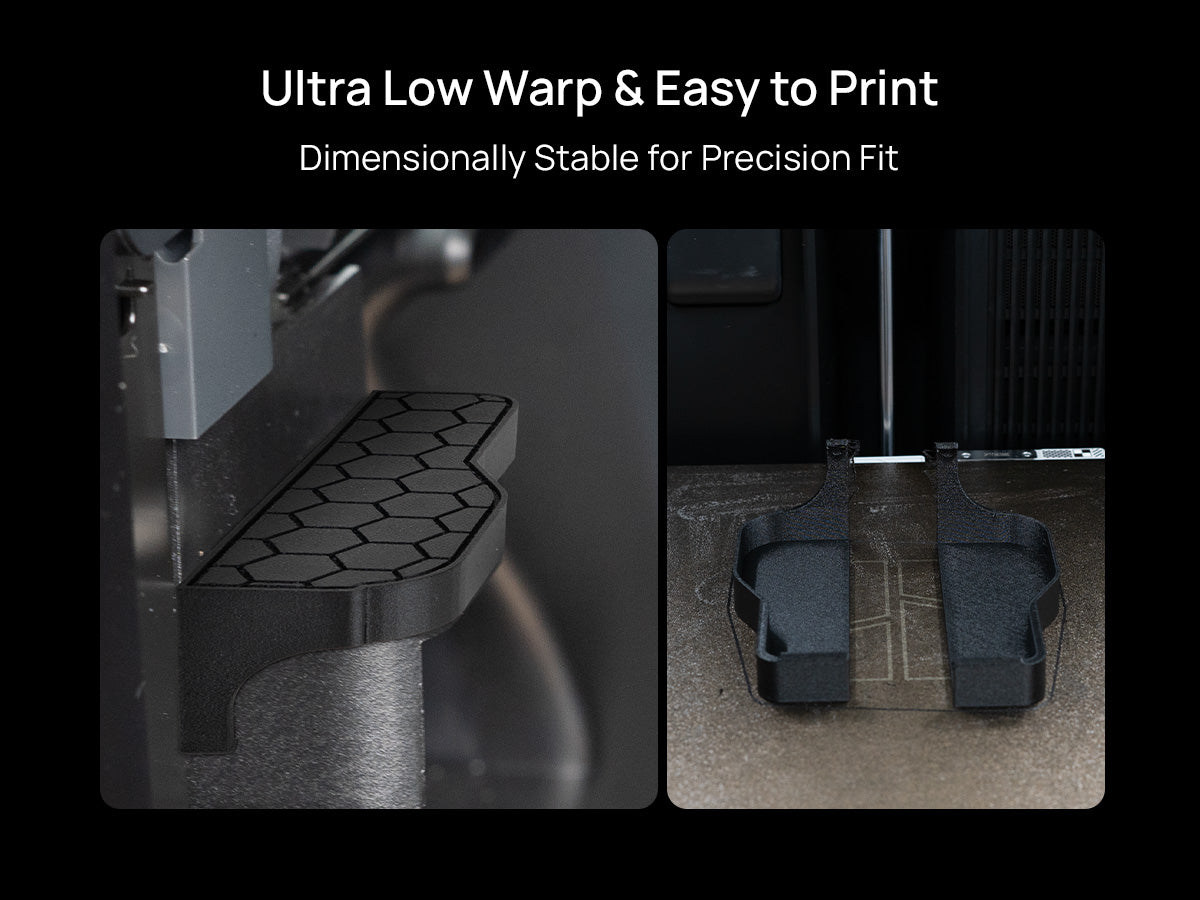

- True "Zero-Warp" Reliability: Reliable dimensional accuracy for large-scale engineering.

- Industrial Resilience: Wear & Oil Resistant, Long-lasting durability in demanding environments.

Why choose TPU-GF?

Mechanical parts

Wearable device

Industrial equipment

Buffer grip

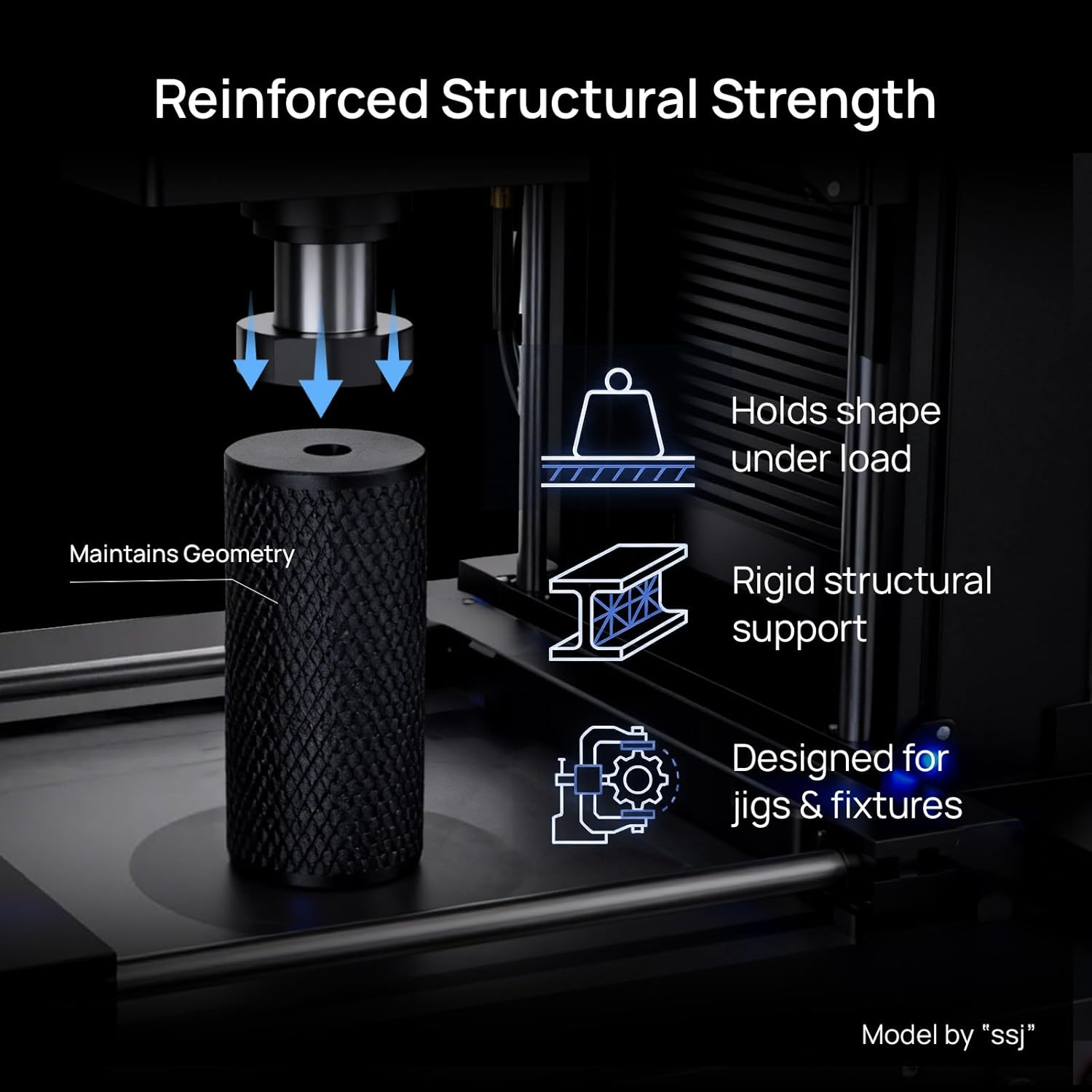

Stiff Yet Tough

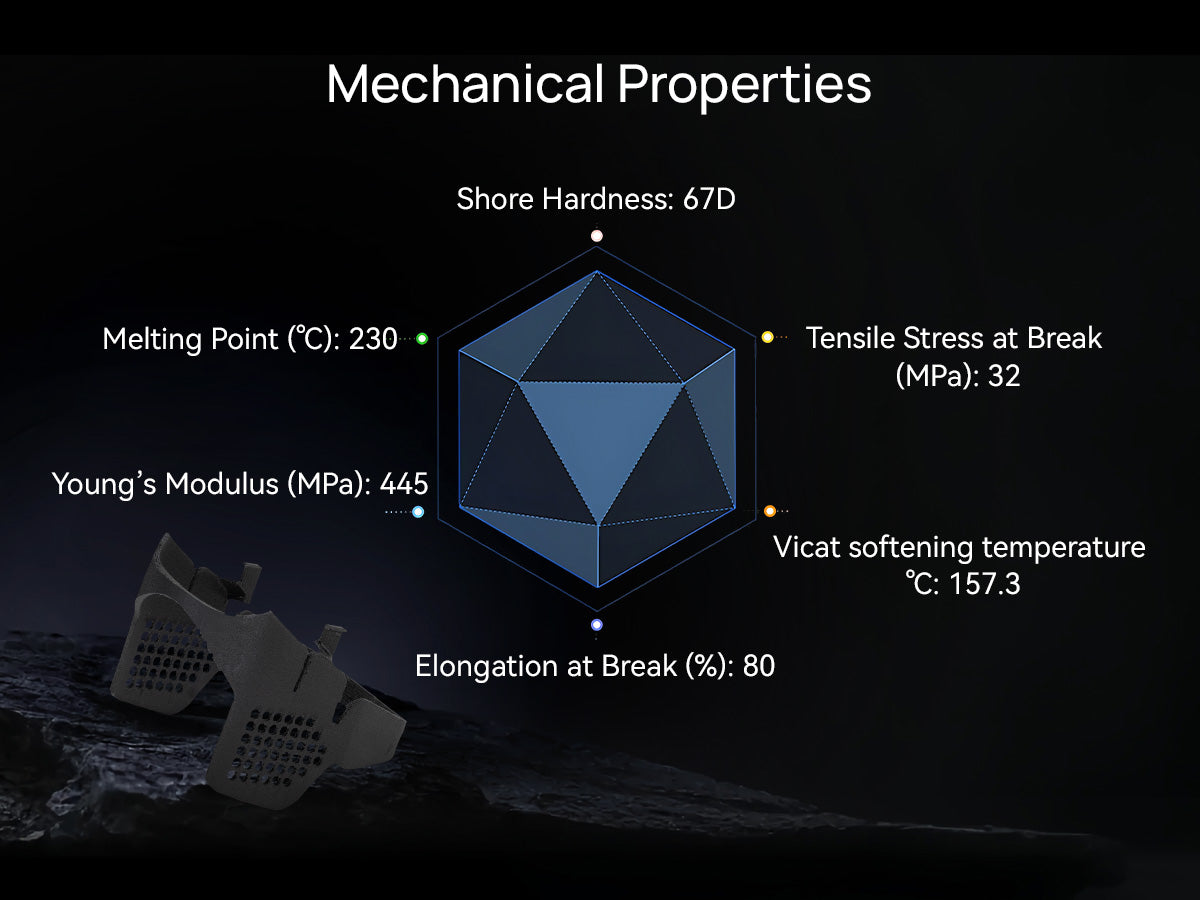

67D TPU-GF base absorbs energy. It’s rigid enough to hold loads, but tough enough to survive drops.

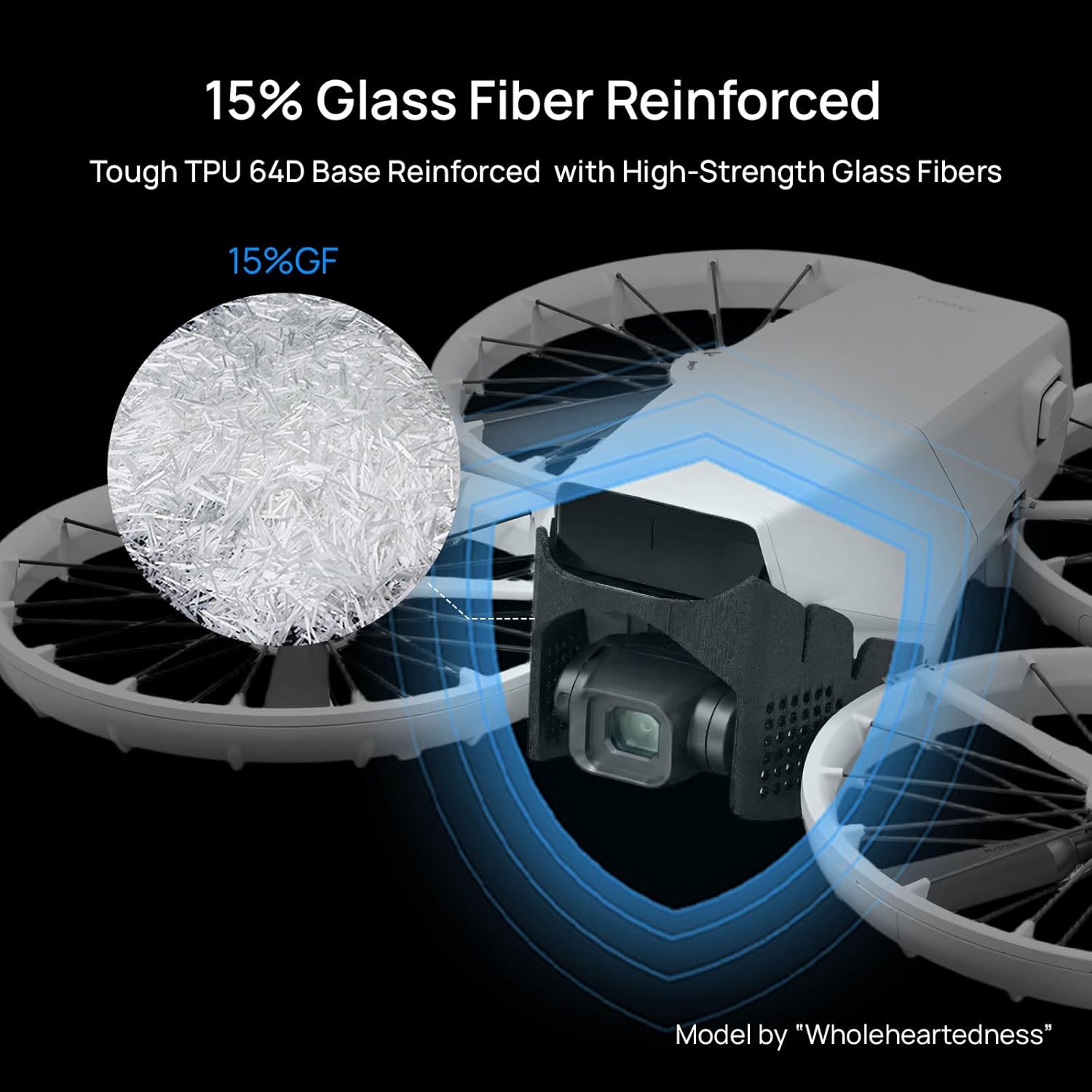

15% Glass Fiber Reinforced

The Perfect Balance of Strength & Flexibility.

15% glass fibers create a structural "skeleton" within the TPU, providing the dimensional stability and load-bearing strength needed for industrial tools while significantly reducing warping and shrinkage during printing.

Maximum Vibration Damping

The TPU-GF matrix acts as a natural shock absorber. It soaks up high-frequency jitter that rigid plastics simply transmit.

Industrial Wear& Chemical Resistance

Engineered with a reinforced surface to resist heavy abrasion and friction, also offers superior resistance to automotive oils, greases, and common solvents, making it the ideal choice for high-wear mechanical parts, workshop tools, and under-the-hood prototypes.

Hidden Layer Lines

High GF content diffuses light, creating a stunning matte black finish. Achieve a professional "factory-molded" look straight off the bed.

Engineering Precision

Internal glass fibers act as a stabilizing skeleton for an ultra-low warp experience, delivering enhanced dimensional stability that prevents corner lifting on large-scale prints and ensures a perfect fit for tight-tolerance jigs and interlocking mechanisms.

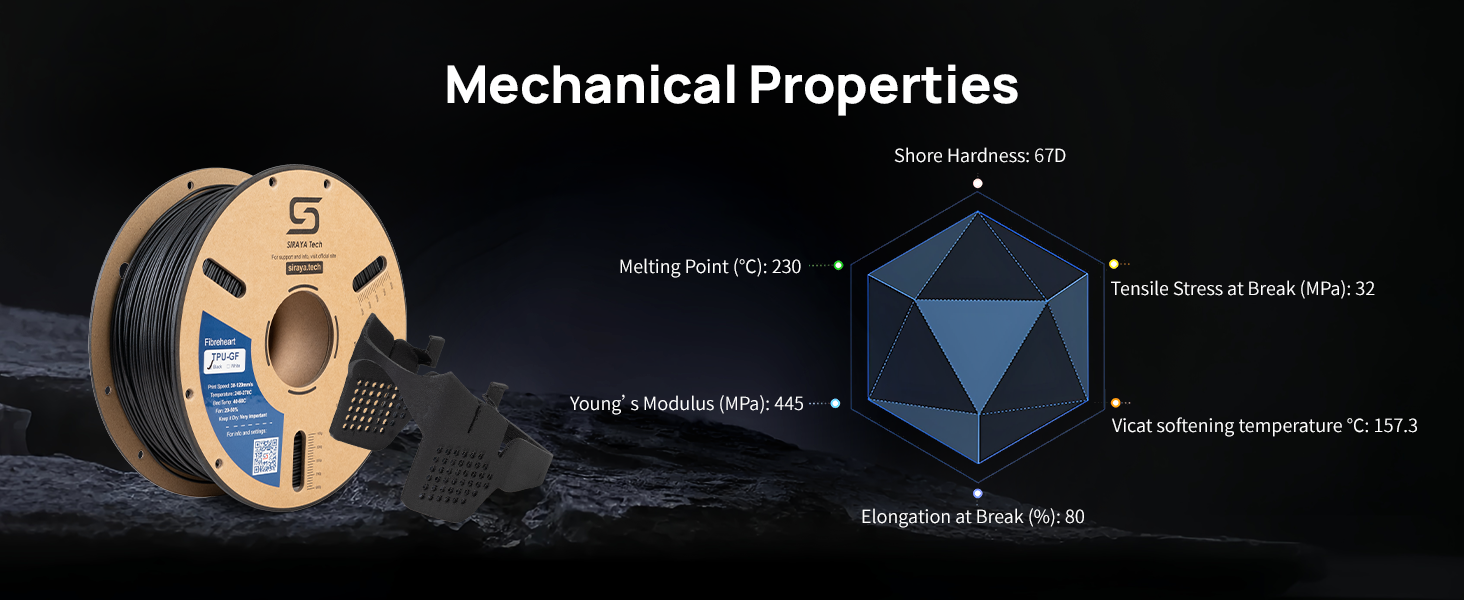

Product Specifications

| Diameter | 1.75mm (+/- 0.03mm) |

| Net Weight | 1kg |

| Nozzle | Hardened Steel Required (0.4mm or larger) |

| Print Temp | 240°C – 270°C |

| Bed Temp | 40°C – 60°C |

| Shore Hardness | 67D |

| Flexural Modulus | 1200 MPa |

Gallery

FAQ

Yes. Unlike standard soft TPU, TPU-GF features a 64D Shore hardness and glass fiber reinforcement, providing the necessary rigidity for smooth loading and unloading in the AMS and AMS Lite. It feeds reliably without tangling or jamming in the PTFE tubes.

Yes, a Hardened Steel Nozzle is strictly required. Glass fiber is abrasive and will quickly wear down standard brass nozzles. To maintain print precision and prevent extrusion issues, we recommend a hardened steel nozzle with a diameter of 0.4mm or larger.

At Shore 64D, it feels more like a tough engineering plastic (similar to a hard hat) than rubber. It won't stretch like 95A TPU, but it retains the ability to absorb massive impacts and vibrations without shattering.

TPU-GF has excellent dimensional stability and low shrinkage. A heated bed at 40-60°C with a clean PEI sheet or Engineering Plate is usually sufficient. For very large parts, a thin layer of glue stick can help facilitate easier release after the print cools.

Yes. It offers excellent resistance to most industrial oils, greases, and common solvents. This makes it an ideal material for automotive prototypes, manufacturing jigs, and workshop tools that come into contact with chemicals.