Recently viewed

Carbon fiber nylon filament delivers industrial-strength performance when you need parts that won't break, warp, or fail under stress. At Siraya Tech, our carbon fiber nylon collection combines the toughness of nylon with the reinforcing power of carbon fibers, creating prints that rival injection-molded parts. Perfect for functional prototypes, automotive components, and demanding mechanical applications where standard filaments simply aren't strong enough.

Carbon Fiber Nylon Filament Built for Maximum Strength and Durability

When your project demands the ultimate in strength-to-weight ratio, carbon fiber nylon filament delivers unmatched performance that outlasts traditional materials.

- Superior tensile strength exceeds most engineering plastics

- Lightweight yet incredibly rigid for aerospace-grade applications

- Excellent heat deflection temperature for high-temp environments

- Outstanding impact resistance prevents cracking under stress

- Dimensional stability maintains precision even in demanding conditions

Enhanced Stiffness for Load-Bearing Applications

Carbon fiber reinforcement transforms flexible nylon into a rigid, structural material capable of handling serious mechanical loads without deformation.

- Increased modulus of elasticity reduces flex under load

- Maintains shape integrity in thin-walled structures

- Perfect for brackets, mounts, and structural components

- Reduced creep ensures long-term dimensional stability

- Ideal for replacing metal parts in weight-sensitive applications

Complement your high-performance printing with our engineering resin collection for precision prototyping applications.

Professional Surface Finish and Aesthetics

Unlike basic reinforced filaments, our carbon fiber nylon produces parts with an attractive matte finish that looks as professional as it performs.

- Distinctive carbon fiber surface texture adds visual appeal

- Minimal layer lines create smooth, production-ready finishes

- Excellent detail reproduction for complex geometries

- Consistent color and appearance across entire prints

- Reduced post-processing time compared to standard nylon

Reliable Printing Performance Despite Advanced Properties

Advanced materials shouldn't mean advanced headaches. Our carbon fiber nylon filament is formulated for consistent results with proper setup.

- Optimized flow characteristics prevent nozzle clogging

- Controlled warping through engineered polymer blends

- Good layer adhesion creates strong, unified parts

- Compatible with enclosed printer setups for best results

-

Moisture-resistant packaging maintains material integrity

For applications requiring transparency and chemical resistance, explore our Fibreheart PET filament family collection.

Perfect for High-Performance Applications

Carbon fiber nylon filament opens up possibilities that were previously limited to expensive manufacturing processes or metal fabrication.

- Automotive components including brackets, ducts, and housings

- Drone frames and aerospace parts requiring strength-to-weight optimization

- Industrial tooling, jigs, and fixtures for manufacturing

- Robotics components that need precision and durability

- Custom mechanical parts for engineering prototypes

For flexible applications requiring similar durability, discover our flexible resin Tenacious family for bendable high-performance parts.

Why Choose Siraya Tech Carbon Fiber Nylon Filament

Premium materials require premium quality control. Our carbon fiber nylon filament delivers consistent performance through rigorous testing and formulation.

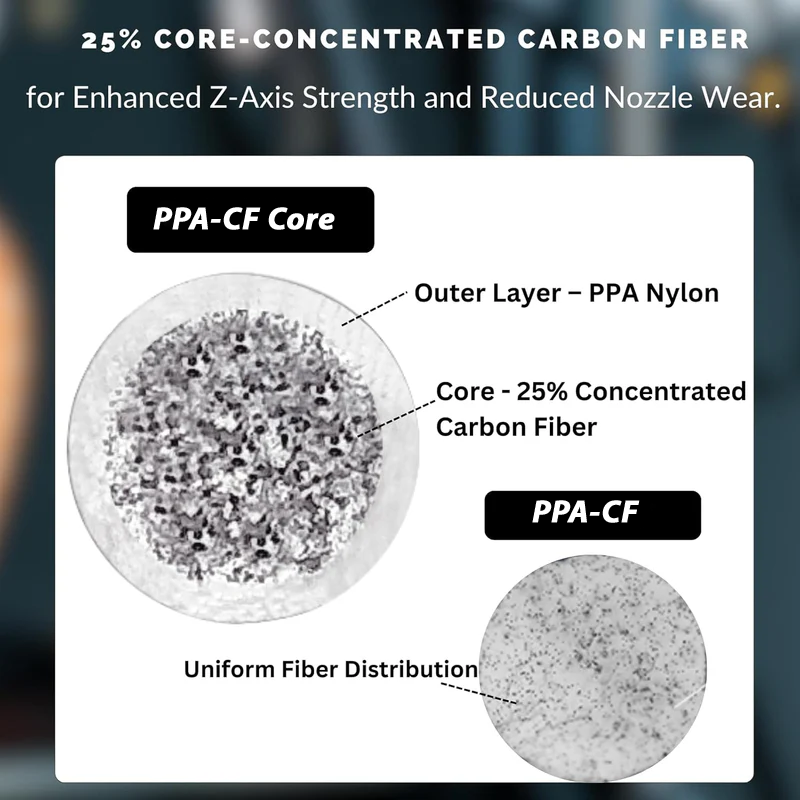

- Balanced carbon fiber content optimizes strength without compromising printability

- Consistent diameter tolerance ensures reliable feeding and extrusion

- Quality-tested batches guarantee repeatable results across spools

- Clear printing guidelines help you achieve optimal results

- Technical support for challenging applications and troubleshooting

FAQs About Carbon Fiber Nylon Filament

What is carbon fiber nylon filament?

Carbon fiber nylon filament is a composite material combining nylon polymer with chopped carbon fibers for reinforcement. The carbon fibers significantly increase strength, stiffness, and dimensional stability while maintaining nylon's chemical resistance. It's designed for functional parts requiring superior mechanical properties compared to standard thermoplastics.

Is carbon fiber nylon filament strong?

Yes, carbon fiber nylon filament is among the strongest 3D printing materials available. The carbon fiber reinforcement dramatically increases tensile strength, flexural modulus, and impact resistance compared to unreinforced nylon. It can often replace metal components in non-critical applications while offering significant weight savings.

What temperature do you print carbon fiber nylon?

Carbon fiber nylon typically prints at 250-280°C nozzle temperature with a heated bed at 80-100°C. An enclosed printer is highly recommended to prevent warping and ensure consistent results. These temperatures require an all-metal hotend and often benefit from a hardened steel nozzle.

Can any 3D printer use carbon fiber filament?

Not all 3D printers can handle carbon fiber filament effectively. You need an all-metal hotend capable of 280°C, preferably a hardened steel nozzle, and ideally an enclosed chamber. The abrasive carbon fibers will quickly wear standard brass nozzles, and proper bed adhesion requires heated surfaces.