Recently viewed

Thermoplastic elastomer filament opens up new possibilities for creating soft, flexible parts that feel natural and perform reliably. At Siraya Tech, our TPE collection is designed for makers who need materials softer than typical TPU—think grip handles, soft-touch surfaces, and cushioning components that compress and recover smoothly. With engineered flow properties and consistent quality, these materials deliver the gentle flexibility your projects demand without the usual printing complications.

Thermoplastic Elastomer Filament Delivers Exceptional Softness and Comfort

When your project requires the softest possible touch or maximum comfort, thermoplastic elastomer filament provides unmatched gentle flexibility that feels right.

- Ultra-soft shore hardness ratings as low as 70A for maximum flexibility

- Excellent compression recovery maintains shape after repeated use

- Skin-safe formulations perfect for wearables and contact applications

- Superior grip properties for ergonomic handles and tools

- Consistent softness throughout the entire printed part

Enhanced Printability for Advanced Flexible Materials

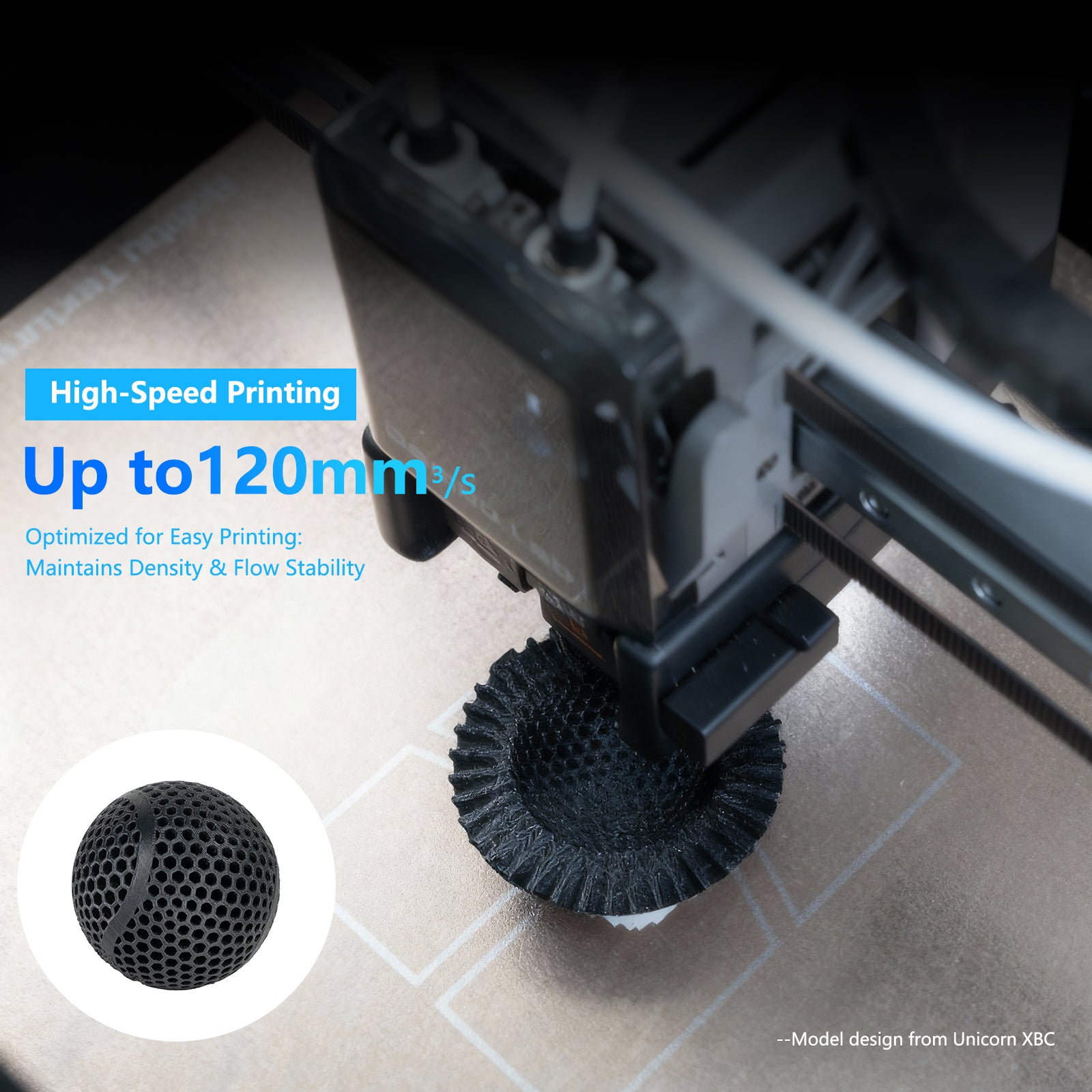

TPE filament can be challenging, but our formulations are engineered to flow smoothly and layer consistently for reliable results every time.

- Optimized melt flow prevents jamming in extruder mechanisms

- Reduced stringing and oozing compared to standard elastomers

- Improved layer adhesion creates strong bonds despite flexibility

- Compatible with direct drive systems and properly tuned setups

-

Stable extrusion temperatures for consistent print quality

Explore our comprehensive 3D printer filament range for rigid materials that complement flexible components perfectly.

Durability That Handles Daily Use and Abuse

Soft doesn't mean weak. Our thermoplastic elastomer filament maintains its properties through repeated compression, stretching, and environmental exposure.

- Excellent fatigue resistance for parts used thousands of times

- Chemical resistance to common household and industrial substances

- Temperature stability maintains flexibility across wide temperature ranges

- UV-resistant formulations prevent degradation from sunlight exposure

- Maintains elasticity and softness over extended periods

Perfect for Human-Contact Applications

Thermoplastic elastomer filament excels in applications where comfort, grip, and user experience matter most—areas where harder materials simply don't work.

- Ergonomic grips and handles for tools and equipment

- Soft-touch surfaces for consumer electronics and appliances

- Wearable devices that need to flex with body movement

- Cushioning and padding for protective equipment

- Medical and assistive devices requiring skin-friendly materials

For slightly firmer flexible applications, check out our TPU filament collection with different hardness options.

Why Choose Siraya Tech Thermoplastic Elastomer Filament

Premium soft materials require careful formulation and quality control. Our TPE filaments deliver consistent performance through rigorous testing and engineering.

- Balanced additive packages optimize both printability and performance

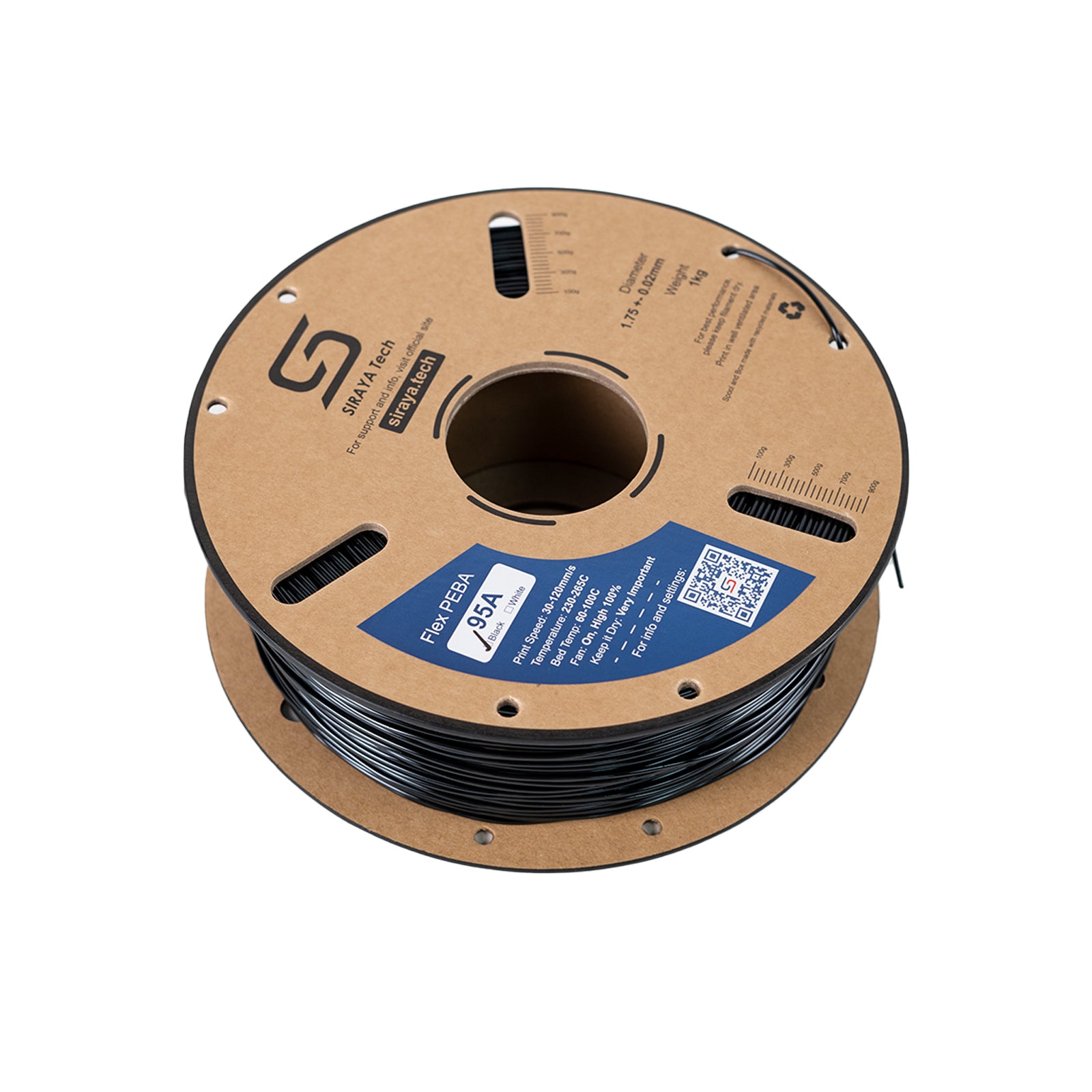

- Consistent diameter tolerance ensures reliable feeding and extrusion

- Quality-tested batches guarantee repeatable softness and flexibility

- Clear printing guidelines help achieve optimal results

- Technical support for challenging applications and setup optimization

For applications requiring crystal clarity and chemical resistance, explore our PETG filament collection.

Versatile Applications Across Multiple Industries

From consumer products to specialized equipment, thermoplastic elastomer filament enables designs that prioritize user comfort and tactile experience.

- Gaming controllers and input devices with comfortable grips

- Footwear components including insoles and comfort padding

- Automotive interior parts requiring soft-touch surfaces

- Sporting goods and fitness equipment with enhanced grip

- Art and design projects exploring texture and tactile interaction

FAQs About Thermoplastic Elastomer Filament

What is TPE filament good for?

TPE filament excels at creating very soft, flexible parts like grip handles, cushioning, and wearable components. It's ideal for applications requiring maximum comfort, skin contact, or very gentle compression. TPE is softer than TPU, making it perfect for ergonomic surfaces and parts that need to feel natural and comfortable.

Is TPE toxic to print?

Quality TPE filaments are generally safe to print when used properly with adequate ventilation. Like most thermoplastics, TPE can produce fumes during printing, so use in well-ventilated areas. Many TPE formulations are skin-safe once printed and cured, but always check specific material safety data sheets for your application.

Can you 3D print thermoplastic elastomer?

Yes, thermoplastic elastomer can be 3D printed, though it requires careful setup and typically works best with direct drive extruders. TPE needs slower print speeds, proper temperature control, and careful retraction settings. The material's extreme flexibility can cause feeding challenges, but quality formulations are engineered for better printability.

What is the difference between TPE and TPU filaments?

TPE is generally softer and more flexible than TPU, with lower shore hardness ratings. TPU offers better printability and durability, while TPE provides superior softness and comfort. TPU is better for functional parts needing strength, while TPE excels in applications prioritizing comfort, grip, and gentle flexibility.