Recently viewed

Level up your 3D printing with Siraya Tech UV resin—engineered for makers who demand precision, durability, and stunning surface detail.

At Siraya Tech, we design resins that cure fast, print clean, and deliver professional-grade results for every project—from tabletop miniatures to high-temp molds.

Whether you need ultra-clear finishes, flexible strength, or heat-resistant performance, our UV resins are built to make your prints look and perform better.

Print Sharper, Stronger, and Smarter with Siraya Tech UV Resin

Our UV resins are made for creators who care about quality and consistency. Each formula is tuned for high resolution, strong adhesion, and easy post-processing.

High Precision Every Time

Siraya Tech UV resin captures fine details and smooth finishes, making it ideal for intricate designs and functional parts.

- Delivers crisp edges and clean surfaces

- Reduces warping and shrinkage for accurate fits

- Perfect for miniatures, prototypes, and fitted models

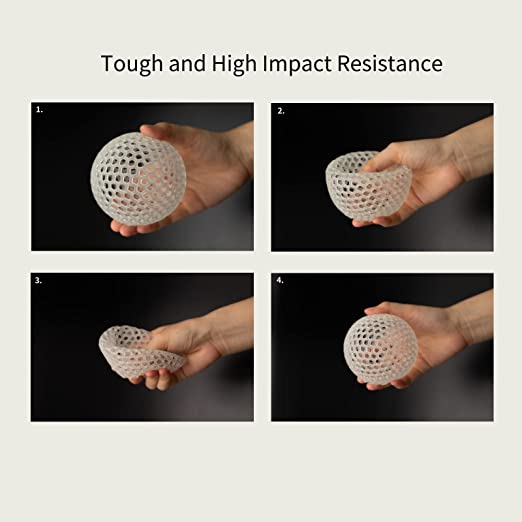

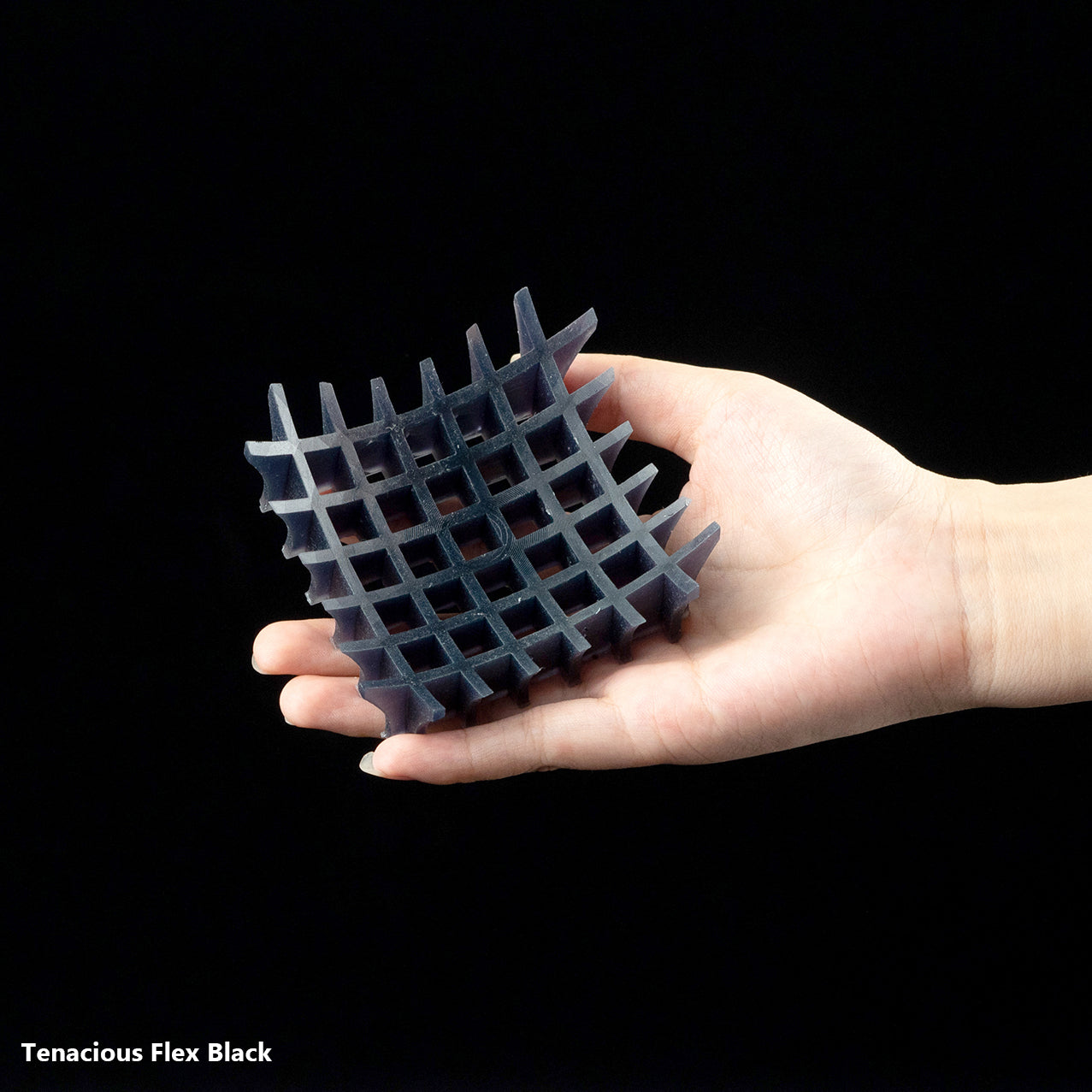

Built Tough for Real-World Use

Our engineering-grade UV resins balance hardness and flexibility—no more brittle prints that crack under pressure.

- Withstands stress and impact for durable results

- Ideal for tappable, drillable, and load-bearing parts

- Maintains shape and strength even after curing

Create Without Limits with Specialty UV Resins

Siraya Tech offers UV resins that go beyond standard printing—crafted for creative, industrial, and high-performance applications.

High-Temperature and Chemical-Resistant Power

For industrial and molding applications, Sculpt UV resin handles extreme heat and harsh conditions.

- Withstands up to 250°C for injection molds and vacuum forming

- Offers strong chemical resistance and low water absorption

- Perfect for dental, jewelry, and vulcanized rubber processes

Easy Printing, Fast Curing, and Low Odor

Siraya Tech UV resins are designed to make your printing process smoother from start to finish.

Cleaner Workflow, Faster Results

Spend less time cleaning and more time creating.

- Rapid UV curing for quick turnaround

- Low odor and easy-to-clean formula

- Works seamlessly with popular resin printers like Elegoo, Anycubic, and Creality

Suggested Collections to Explore

Take your 3D printing further with these related collections:

- Flexible Filaments– Perfect for parts that bend and flex without breaking.

- Carbon Fiber Filament – Add strength and stiffness to your 3D prints.

- FDM Filament – Reliable and versatile for everyday printing projects.

- Black PLA Filament– Smooth, consistent, and ideal for striking visual contrast.

FAQs About UV Resin

Is UV resin better than epoxy resin?

UV resin cures faster and is ideal for small or detailed 3D prints, while epoxy resin takes longer to harden and suits larger projects. UV resin offers smoother finishes and higher precision, making it a top choice for 3D printing and modeling. However, epoxy is often more durable for thick layers or casting applications.

What is UV resin used for?

UV resin is used in 3D printing, jewelry making, and crafting for creating detailed, durable, and smooth objects. It’s ideal for small models, prototypes, lenses, and molds that need fine detail and quick curing. The resin hardens under UV light, giving you strong, accurate parts in minutes.

What does UV resin do to your lungs?

Uncured UV resin can release fumes that may irritate your lungs if inhaled over time. Always use it in a well-ventilated area or with a respirator. Once cured, UV resin is stable and safe to handle, but safety precautions during printing are important to avoid respiratory irritation.

Does UV resin harden on its own?

No, UV resin does not harden on its own. It needs exposure to UV light to cure and solidify. Without UV light, the resin will remain in liquid form indefinitely, so using a UV lamp or natural sunlight is essential for proper curing.

Can UV resin be mixed with other materials?

Yes, UV resin can be mixed with pigments, dyes, or flexible additives to achieve custom effects. Many makers mix it with tough or flexible resins for better performance. Always test small batches to ensure consistent curing and strength.