Description

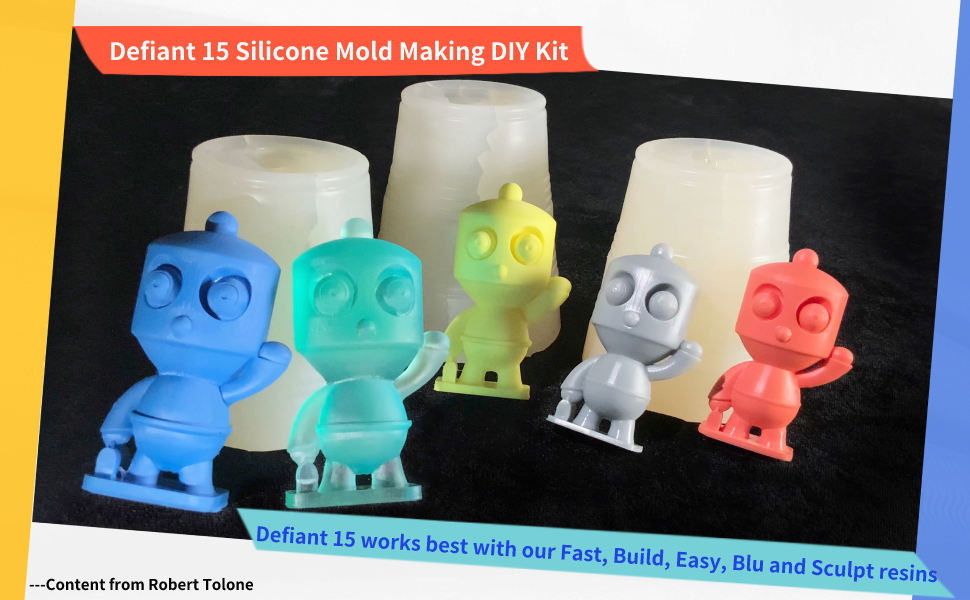

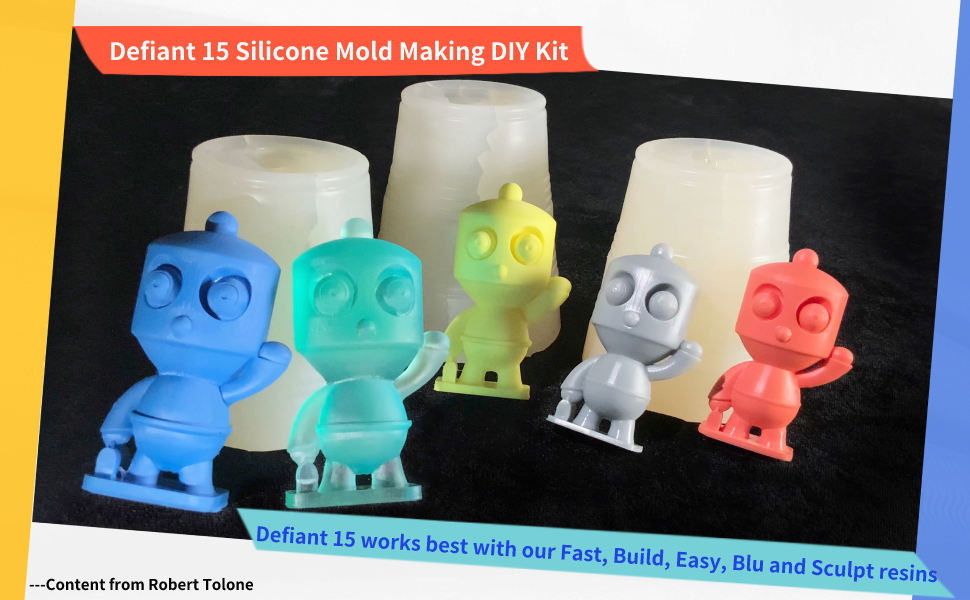

- 【Exceptional Curing Inhibition Resistance】Defiant 15 enhances resistance against UV resin curing inhibition, outperforming traditional silicones. Submerge parts in water for 30 minutes for perfect cures without clear coating, ideal for our Fast, Build, Blu, Easy and Sculpt resins.

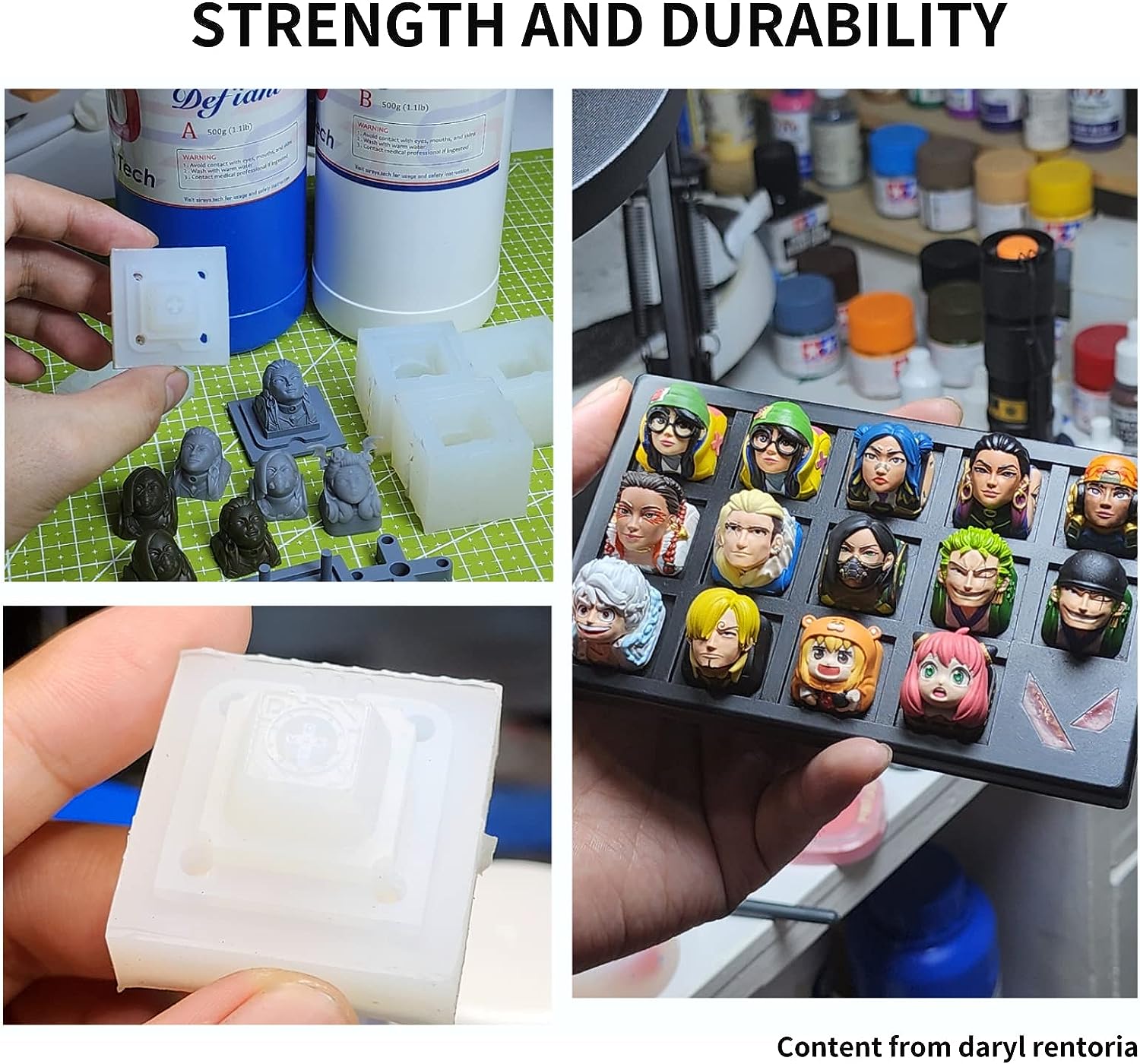

- 【Strength and Durability】Siraya Tech's Defiant 15 offers unmatched flexibility and tear resistance. It's reusable, provides cost-effective, durable casting, and withstands temperatures up to 200°C, ensuring longevity.

- 【Low Viscosity】Defiant 15 simplifies mold making with its lower viscosity, allowing for easy pouring and bubble-free results without needing professional equipment, making it beginner-friendly.

- 【Versatile & Food Safe】Safe for food applications, Defiant 15 is perfect for a wide range of molding needs from culinary to artistic, offering an ideal balance of hardness and flexibility for DIY enthusiasts.

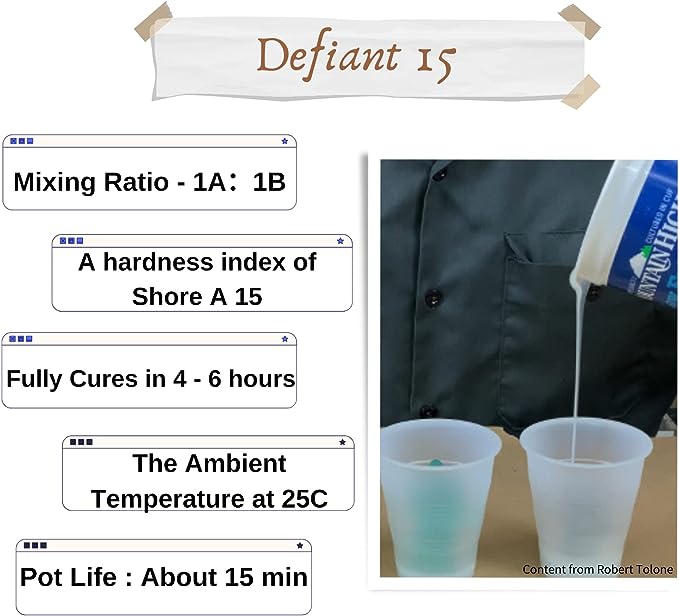

- 【Effortless 1A:1B Mixing Ratio】With a simple 1:1 mixing ratio, Defiant 15 guarantees a self-degassing, bubble-free silicone, making it accessible for beginners with support available.

Estimate shipping

Please note

Shipping will be calculated based on the products in the cart.

Payment & Security

Features

- Hardness index of Shore 15A

- Exceptional resistance to silicone poisoning, especially from UV resin

- Minimal post-processing required for proper mold curing

- Ideal balance of hardness and flexibility for general molding applications

- Outstanding material strength, including tear and heat resistance

- Appearance Translucent

- FDA Food Safe.

Technical Data

- Hardness (Shore A) 15

- Density (g/cm3) 1.1

- Tensile strength (Mpa) 5.5

- Elongation (%) 550

- Tear strength (K N/m) 15

- Pot life Approximately 15 minutes

- Full cure time 4-6 hours

- Ambient temperature at 25C

Silicone - Defiant 15

All new Defiant 15 from Siraya Tech with extra resistance to platinum poisoning without complicated post-processing is perfect for your next project. With just 30 minutes of curing the part submerged in water, Defiant 25 will cure without the part being clear coated.

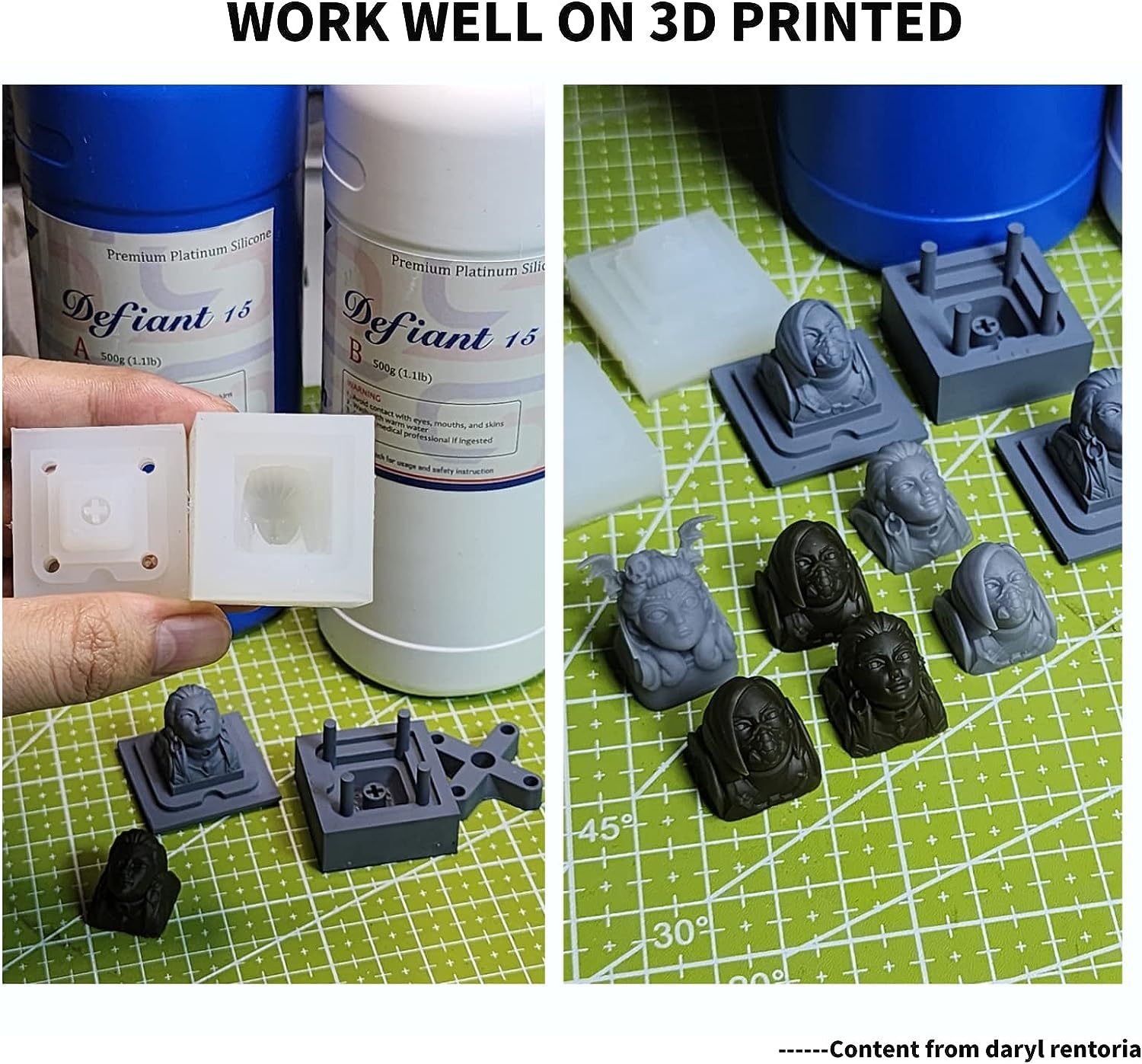

Has good resistance to silicone poisoning, especially due to UV resin. Siraya Tech Defiant 15 requires a lot less post-processing to make mold cure properly.

Platinum silicone poisoning presents a unique challenge, as it arises not only from 3D printing resins but also from the silicone manufacturing process itself. To achieve the best possible results, it's crucial to identify the ideal combination of silicone and resins. Defiant 15 has been engineered to exhibit greater tolerance compared to traditional platinum silicone; however, certain resins inherently offer better compatibility with silicone and necessitate less post-processing.

Resin Selection and Post-Processing: Essential for 3D UV Resin Prints.

Ideal with 3D Printing UV Resin

Defiant 15 liquid silicone has extra resistance to curing inhibition, No coating is needed. It works best with our Fast, Build, Blu, Easy and Sculpt resins.

Tear Resistant & Longevity

Compared with others, Defiant 15 has better flexibility and stronger tear resistance, and silicone rubber has a longer life span and can be reused many times.

Thinner Viscosity

This clear silicone mold making is easy to pour and degas, and it's thinner, making it perfect for beginners.

How to use Silicone Defiant 15

1. Mixing A part and B part

Mix Siraya Tech Defiant 15 clear platinum mold making silicone rubber part A and part B in 1:1 by weight (or volume)

2. Stir well

Then stir the silicone mold making rubber for 5 minutes. Make sure to stir the liquid rubber mixture well for better results.

3. Poring into the mold frame

Pour the fully stirred mold making silicone into the film frame, pot life is about 15 minutes and fully cures in 4 - 6 hours (ambient temperature at 25C)

4. Demoulding

Siraya Tech liquid silicone rubber is very easy to release from molds and the resulting molds are very flexible. Even beginners can make their own molds very easily.

Check out this video from Robert on Silicone Use