Description

- Fast-Rebounding & Flexible – Designed for quick shape recovery and impact absorption.

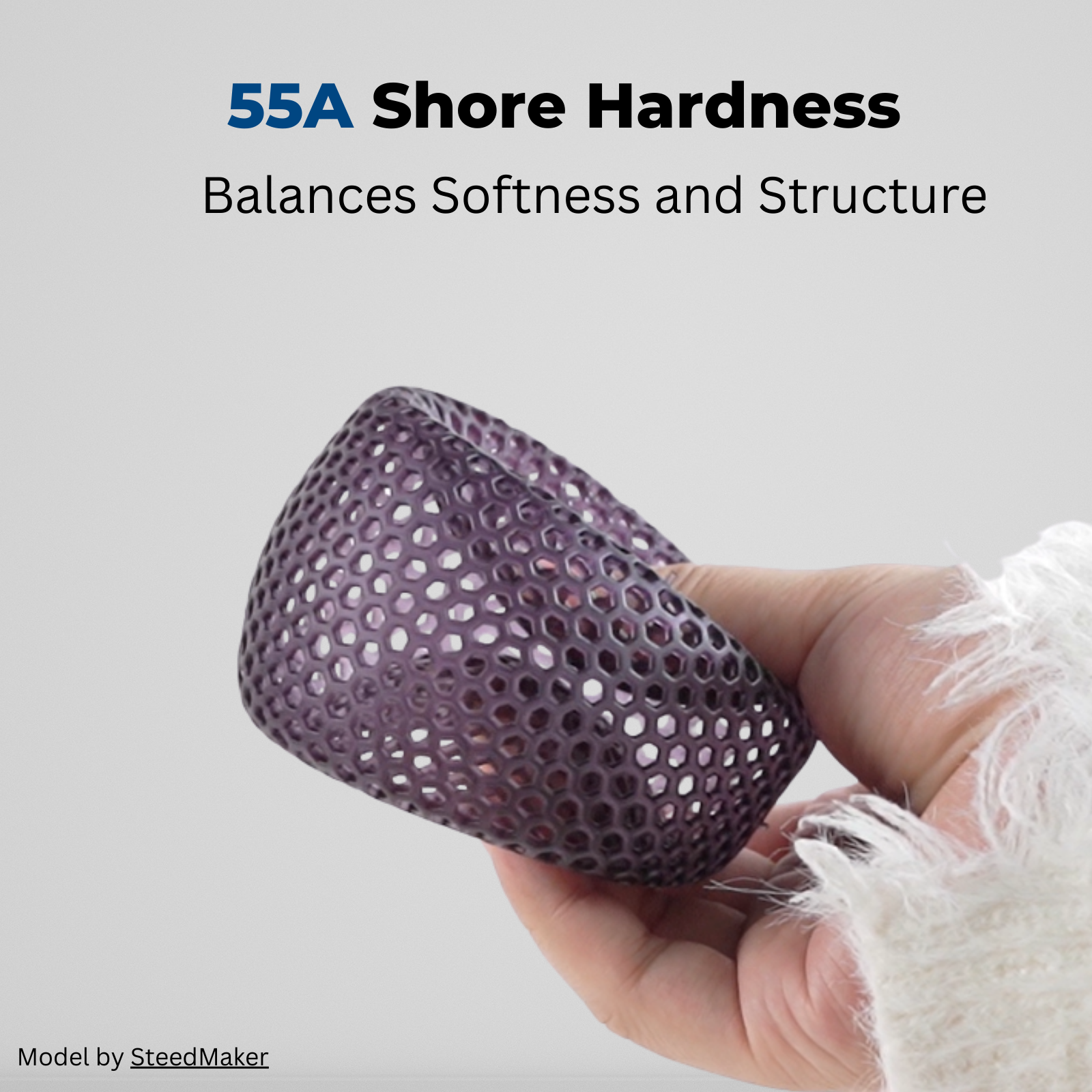

- 55A Shore Hardness – Softer than Tenacious Flex, with excellent elasticity.

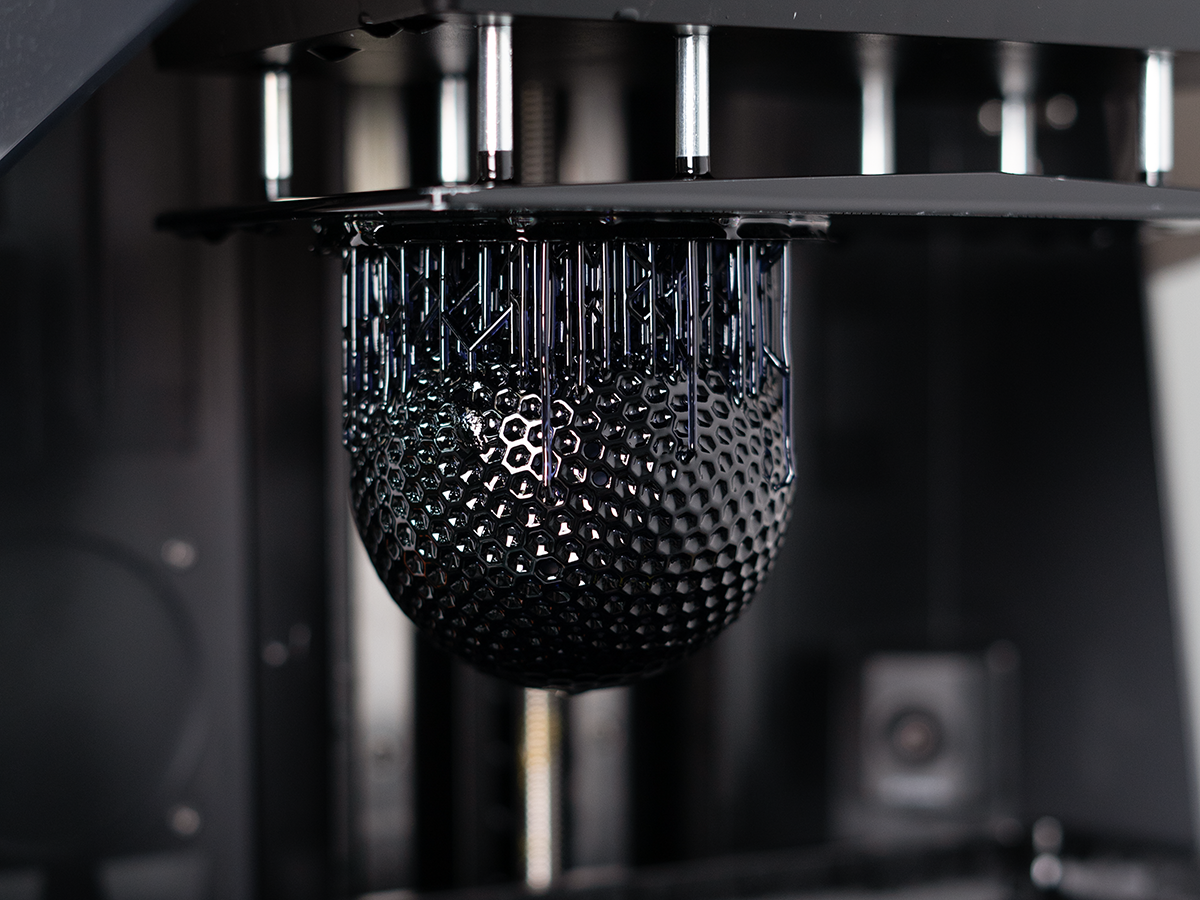

- Broad Compatibility – Works with most 405nm LCD and DLP 3D printers.

- Professional Black Finish – Ideal for both prototyping and functional parts.

Key Applications:

- Protective gear prototypes (pads, cushions)

- Shock-absorbing components and dampeners

- Flexible consumer products (phone cases, grips)

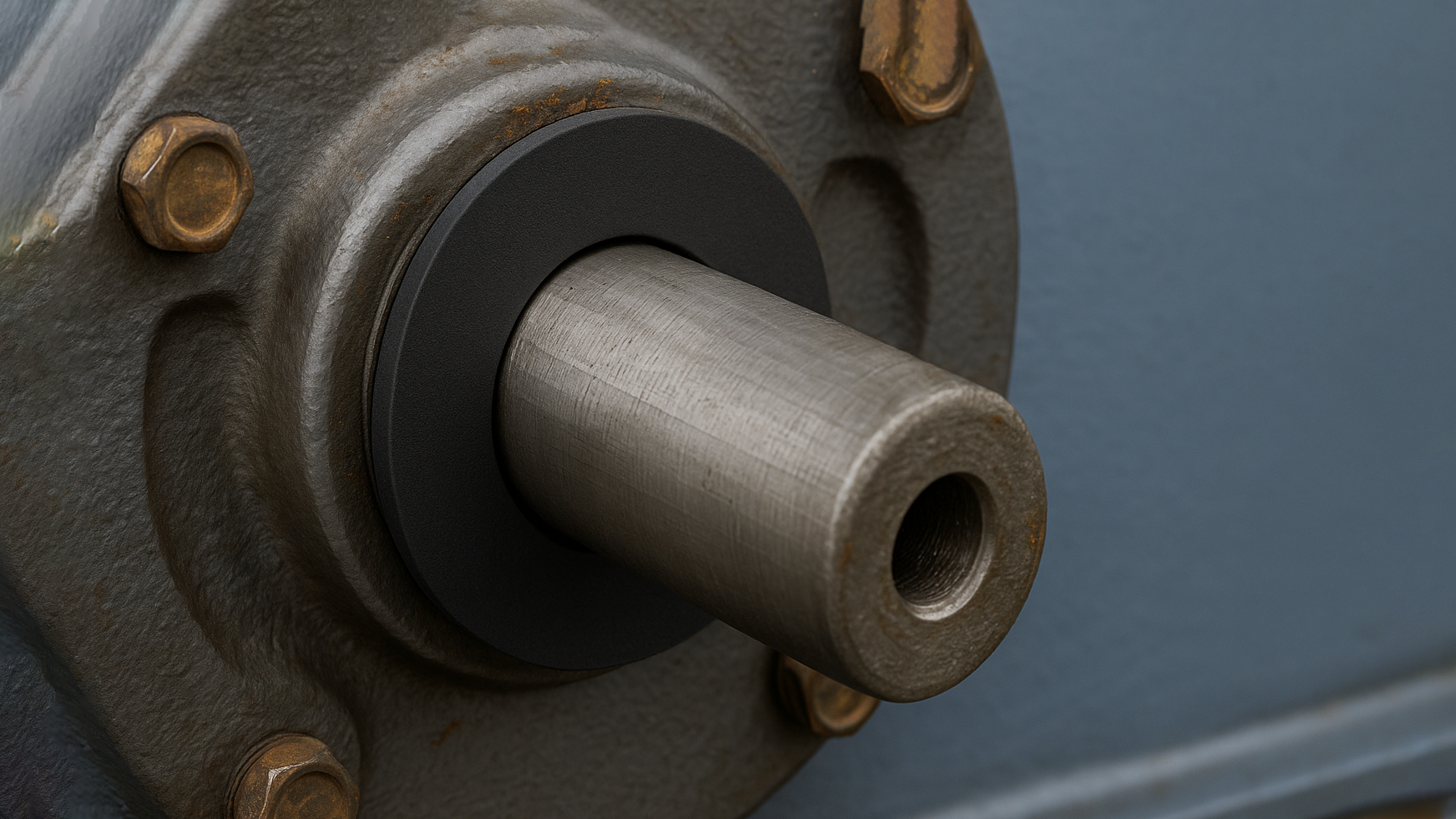

- Industrial seals, gaskets, and soft-touch surfaces

- Sports equipment prototypes (grips, impact zones)

What can you do with Rebound 55A?

💰Consumer grade

🏃 Sports Gear

⚙️Industrial gaskets

Fast Elastic Recovery

Quickly returns to its shape after deformation, making it suitable for the field of shape memory materials.

2-5x Rebound than ordinary flexible resin

Softer and better elasticity than ordinary flexible resin, ideal for shock-absorbing, cushioning, or impact-resistant applications

Balanced 55A Shore Hardness

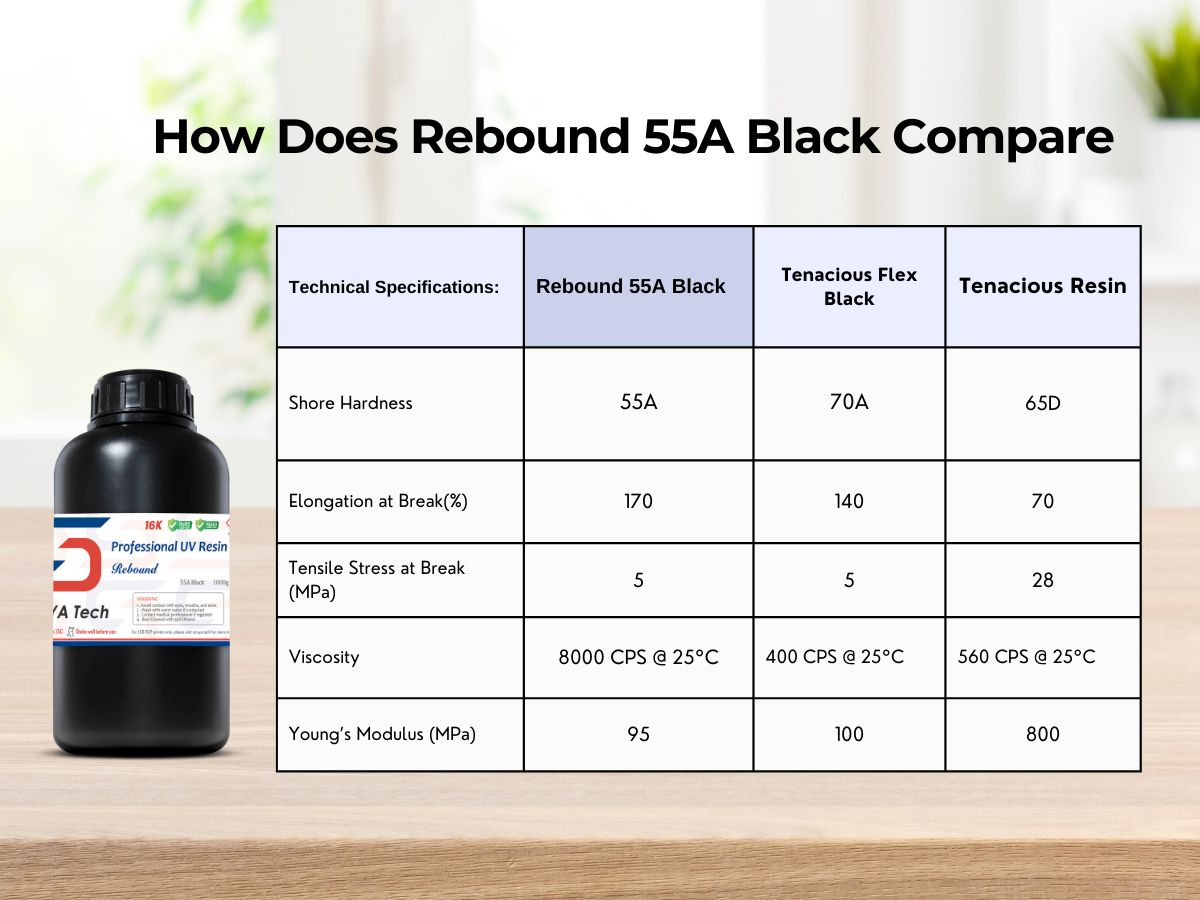

- Softer than Tenacious Flex (70A), while retaining good structure

- Provides a balance between softness and durability

Easy to Print, No Mixing

- Prints like standard resin – no A/B mixing required

- Cleans easily with isopropyl alcohol

- Compatible with most 405nm LCD/DLP printers

Professional Matte Black Finish

- Smooth black surface finish

- Ideal for functional testing or end-use product aesthetics

Specification Data

- Shore Hardness: 55A

- Viscosity: 8000 CPS @ 25°C

- UV Wavelength: 405nm

- Color: Black

Versatile Applications

- Protective gear prototypes (sports pads, cushions)

- Industrial seals, soft gaskets, grips

- Consumer products like phone cases and handle pads

Gallery