In the world of 3D printing, the quest for the perfect print never ends. This test from a Discord user took a step closer to this ideal, focusing on the demolding forces of two different types of films: ACF (Advanced Composite Film) and standard nFEP (Non-Fluorinated Ethylene Propylene).

Test settings:

- Printer:Athena MSLA

- Resin:Atlas Vulcan

- Model:It was a 3.5mm tall Open Ring, 40mm diameter. Base was 0.5mm and Ring was 3mm.

- Settings:0.05mm Layers, 20s Burn-In Layers (4 Transitional), 2.0s Normal Exposure, Lift speed at 2mm/s, Running Peel Detection and Dynamic Wait.

Approach: Three tests with nFEP and two with ACF films were conducted. Sensor readings were consistently recorded during the final eight layers of printing.

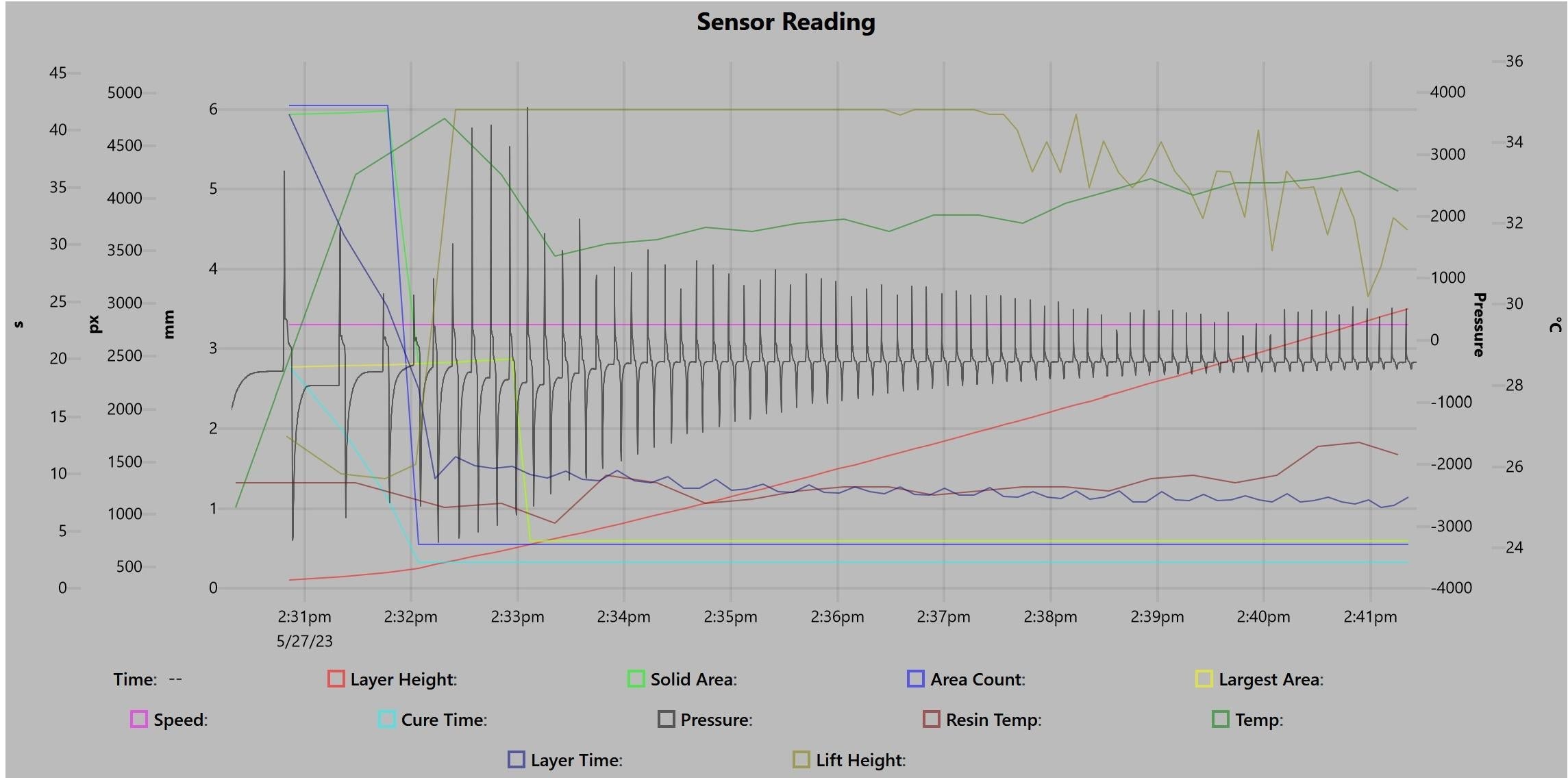

Graphical representations of sensor data taken from the Athena 3D printer

Film test 1:

Film test 2:

Observations: The ACF film outperformed nFEP by reducing the average peel force by about 40%. This reduction was not without trade-offs; the ACF film exhibited more stretch during the peel, resulting in a slightly slower process. However, the lower peak forces suggest a gentler release, which could minimize print failures and potentially extend the film's service life.

Implications: While ACF's longer stretch time may slightly impact print speed, the overall benefit of reduced force suggests a lower risk of print defects. This is particularly advantageous for prints requiring delicate handling or those with intricate details.

If you have any insights on this test and any interpretation of the chart, please share it in the comments. In addition, if you have experience using ACF membrane and NFEP membrane, please share your story.