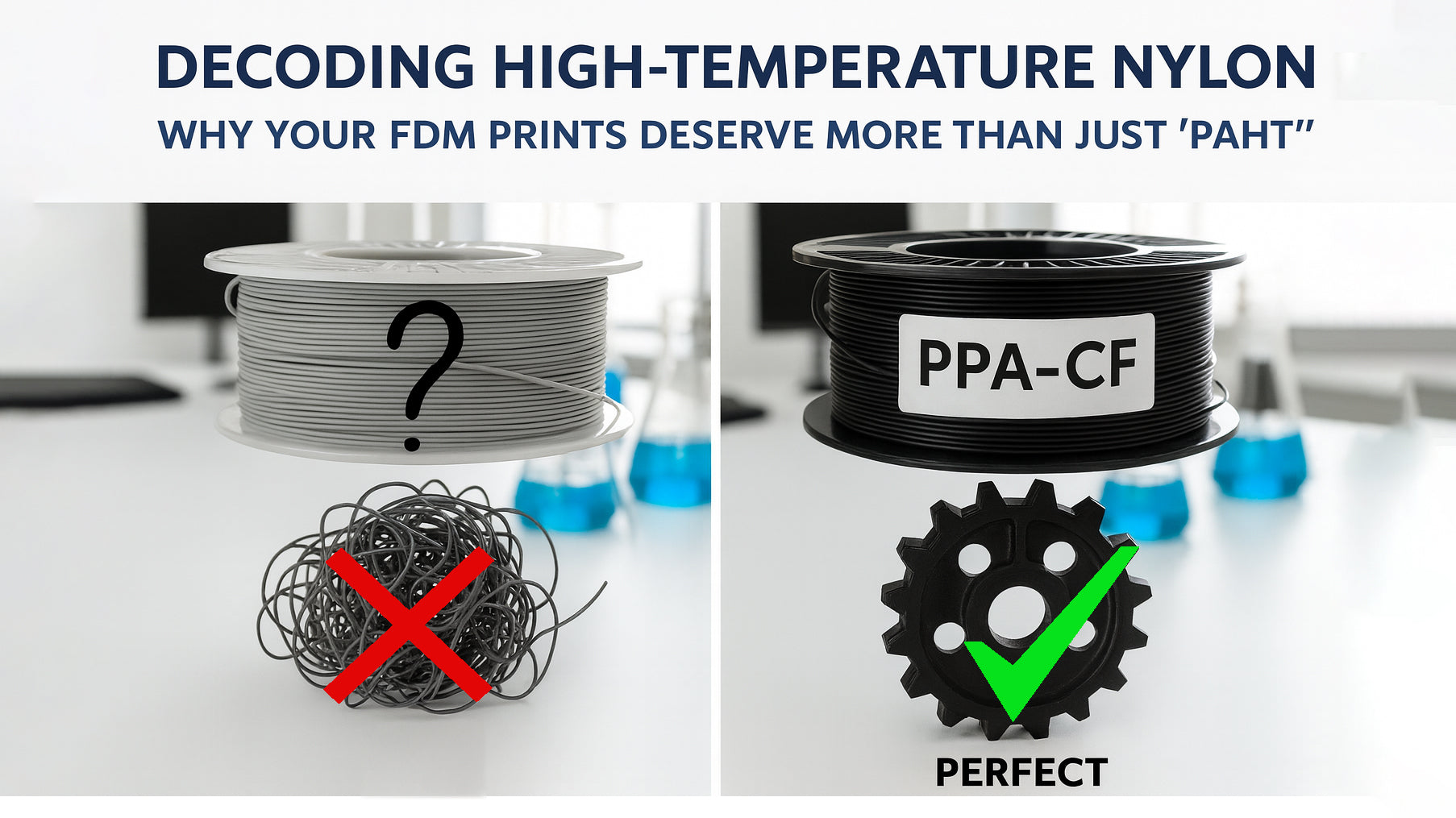

In the world of FDM 3D printing, the leap to engineering-grade materials has been a game-changer. For parts that need to withstand serious stress, heat, and wear, nylon (Polyamide or PA) has long been a go-to choice. But as the market has grown, so has the confusion. We're seeing a flood of terms like "PAHT" (PA High Temperature) and "HTN" (High-Temperature Nylon) used as catch-all marketing labels.

While these sound impressive, they often hide a lack of transparency that can lead to failed prints and subpar parts. At Siraya Tech, we believe in empowering creators with clear, specific information. It's time to look past the buzzwords and demand to know what's actually in your 3D printing filaments.

The Problem: When "High-Temperature" Isn't Clear Enough

"PAHT" and "HTN" are not standardized chemical names; they are marketing categories. A "PAHT" filament from one brand might be a modified PA6, while another could be a PA12 blend. This is a critical issue for engineers, prosumers, and anyone with a demanding application for their 3D printing filaments.

Why does this matter? Because different nylons have wildly different properties:

-

Moisture Absorption (Hygroscopy): This is nylon's biggest challenge. Traditional nylons like PA6 and PA66 are incredibly strong but absorb moisture from the air very quickly. This can ruin a filament spool and lead to weak, inconsistent prints if not dried meticulously.

-

Heat Resistance: While all nylons are relatively heat resistant, the degree of resistance varies significantly between types like PA12 and true high-performance variants.

-

Strength & Stiffness: The base polymer dictates the fundamental mechanical properties of the filament.

Printing a functional jig or an automotive prototype with a vaguely labeled "PAHT" is a gamble. You're guessing about its true heat deflection temperature, its chemical resistance, and, most importantly, how susceptible it is to moisture.

A Call for Clarity: Meet the Real Nylon Family

As an industry, we should move towards using specific chemical names. This allows users to make informed decisions based on proven material science. Here’s a quick guide:

-

PA6 / PA66: The workhorses. Strong and tough, but their high moisture absorption makes them difficult to print reliably without professional drying equipment.

-

PA11 / PA12: More flexible and much less hygroscopic than PA6/66, making them easier to handle. However, they typically offer lower strength and temperature resistance.

-

PPA (Polyphthalamide): This is where true high-temperature performance begins. PPA is a special sub-family of polyamides engineered for extreme environments. It maintains the strength of traditional nylons while offering a significant boost in heat resistance and, crucially, dramatically lower moisture absorption.

When a filament is based on PPA, you're getting a material that is fundamentally more stable, reliable, and capable of performing under pressure.

The Siraya Tech Solution: Engineering-Grade Fibreheart PPA Filaments

In line with our commitment to quality and transparency, we've developed our Fibreheart line around specific, high-performance polymers. When you need a nylon filament for the most demanding engineering applications, our PPA-based materials deliver predictable, top-tier results.

1. Fibreheart PPA

This is our foundational high-performance PPA nylon. It's designed for industrial and engineering applications, offering

extreme strength, superior heat and chemical resistance, and low moisture absorption compared to traditional nylons. Its self-lubricating properties and low coefficient of friction make it perfect for high-wear parts like precision bearings and gears.

2. Fibreheart PPA-CF

We've infused our industrial-grade PPA with 15% chopped carbon fiber to create a composite with

exceptional strength, stiffness, and extreme temperature resistance up to 195°C. The

ultra-low moisture absorption ensures that prints are dimensionally stable and reliable every time, making it ideal for functional automotive components and industrial machinery parts.

3. Fibreheart PPA-CF Core

This filament represents a leap in composite technology. It features carbon fibers concentrated in the filament's core, providing

superior stiffness and strength while reducing abrasive wear on your printer's nozzle compared to standard carbon fiber filaments. This unique structure enhances layer adhesion for exceptional Z-axis strength, perfect for lightweight structural parts in aerospace or high-stress automotive applications.

Your Projects Deserve Precision

Stop gambling on vague marketing terms. For your next engineering project, ask for the specific polymer. Whether you're prototyping a complex mechanical assembly, creating manufacturing aids, or printing end-use parts for extreme environments, understanding the material science is key to success.

Explore the Siraya Tech Fibreheart PPA filament line and experience the performance and reliability that comes from true, transparently labeled engineering materials for FDM 3D printing.

1 comment

sfsdgf

https://bastianfoundation.org/sites/default/files/atencion-espanol.pdf

https://bastianfoundation.org/sites/default/files/atencion-espanol-guia.pdf

https://bastianfoundation.org/sites/default/files/atencion-guia.pdf

https://bastianfoundation.org/sites/default/files/atencion-guia-ayuda-supporto.pdf

https://bastianfoundation.org/sites/default/files/atencion-guia-cliente-espanol-supporto.pdf

https://bastianfoundation.org/sites/default/files/atencion-guia-cliente-supporto-rapida.pdf

https://bastianfoundation.org/sites/default/files/atencion-guia-espanol.pdf

https://bastianfoundation.org/sites/default/files/atencion-guia-espanol-cliente-supporto.pdf

https://bastianfoundation.org/sites/default/files/atencion-guia-espanol-supporto.pdf

https://bastianfoundation.org/sites/default/files/atencion-guia-rapida-cliente-espanol.pdf

https://bastianfoundation.org/sites/default/files/atencion-guia-rapida-supporto.pdf

https://bastianfoundation.org/sites/default/files/atencion-guia-supporto.pdf

https://bastianfoundation.org/sites/default/files/atencion-rapida-cliente-guia.pdf

https://bastianfoundation.org/sites/default/files/atencion-supporto.pdf

https://bastianfoundation.org/sites/default/files/atencion-supporto-cliente.pdf

https://bastianfoundation.org/sites/default/files/ayuda-atencion.pdf

https://bastianfoundation.org/sites/default/files/ayuda-atencion-al-cliente.pdf

https://bastianfoundation.org/sites/default/files/ayuda-atencion-al-cliente-guia.pdf

https://bastianfoundation.org/sites/default/files/ayuda-atencion-cliente.pdf

https://bastianfoundation.org/sites/default/files/ayuda-atencion-cliente-guia-supporto.pdf

https://bastianfoundation.org/sites/default/files/ayuda-atencion-guia-cliente-supporto.pdf

https://bastianfoundation.org/sites/default/files/ayuda-atencion-guia-rapida.pdf

https://bastianfoundation.org/sites/default/files/ayuda-atencion-supporto-guia.pdf

https://bastianfoundation.org/sites/default/files/ayuda-atencion-supporto-rapida-guia.pdf

https://bastianfoundation.org/sites/default/files/ayuda-cliente.pdf

https://bastianfoundation.org/sites/default/files/ayuda-cliente-guia.pdf

https://bastianfoundation.org/sites/default/files/ayuda-cliente-supporto-guia.pdf

https://bastianfoundation.org/sites/default/files/ayuda-espanol-atencion-al.pdf

https://bastianfoundation.org/sites/default/files/ayuda-espanol-atencion-guia.pdf

https://bastianfoundation.org/sites/default/files/ayuda-espanol-guia-atencion-al.pdf

https://bastianfoundation.org/sites/default/files/atencion-al-supporto-guia-rapida.pdf

https://bastianfoundation.org/sites/default/files/atencion-cliente.pdf

https://bastianfoundation.org/sites/default/files/atencion-cliente-ayuda-guia.pdf

https://bastianfoundation.org/sites/default/files/atencion-cliente-espanol-guia-rapida.pdf

https://bastianfoundation.org/sites/default/files/atencion-cliente-espanol-rapida.pdf

https://bastianfoundation.org/sites/default/files/atencion-cliente-guia-ayuda-rapida.pdf

https://bastianfoundation.org/sites/default/files/atencion-cliente-guia-rapida-espanol.pdf

https://bastianfoundation.org/sites/default/files/atencion-cliente-guia-supporto-espanol.pdf

https://bastianfoundation.org/sites/default/files/atencion-cliente-rapida-guia-supporto.pdf

https://bastianfoundation.org/sites/default/files/atencion-cliente-supporto.pdf

https://bastianfoundation.org/sites/default/files/atencion-cliente-supporto-guia-ayuda.pdf

https://bastianfoundation.org/sites/default/files/ayuda-espanol-rapida.pdf

https://bastianfoundation.org/sites/default/files/ayuda-espanol-rapida-guia-supporto.pdf

https://bastianfoundation.org/sites/default/files/ayuda-guia.pdf

https://bastianfoundation.org/sites/default/files/ayuda-guia-cliente-espanol.pdf

https://bastianfoundation.org/sites/default/files/ayuda-guia-espanol.pdf

https://bastianfoundation.org/sites/default/files/ayuda-rapida.pdf

https://bastianfoundation.org/sites/default/files/ayuda-rapida-cliente-supporto-espanol.pdf

https://bastianfoundation.org/sites/default/files/ayuda-rapida-espanol.pdf

https://bastianfoundation.org/sites/default/files/ayuda-rapida-espanol-supporto.pdf

https://bastianfoundation.org/sites/default/files/ayuda-rapida-guia-supporto.pdf

https://bastianfoundation.org/sites/default/files/ayuda-rapida-supporto-cliente.pdf

https://bastianfoundation.org/sites/default/files/ayuda-supporto.pdf

https://bastianfoundation.org/sites/default/files/ayuda-supporto-atencion-cliente.pdf

https://bastianfoundation.org/sites/default/files/ayuda-supporto-cliente-guia-rapida.pdf

https://bastianfoundation.org/sites/default/files/ayuda-supporto-guia-espanol.pdf

https://bastianfoundation.org/sites/default/files/ayuda-supporto-rapida.pdf

https://bastianfoundation.org/sites/default/files/cliente-atencion.pdf

https://bastianfoundation.org/sites/default/files/cliente-atencion-al.pdf

https://bastianfoundation.org/sites/default/files/cliente-atencion-al-rapida-espanol.pdf

https://bastianfoundation.org/sites/default/files/cliente-atencion-guia-ayuda.pdf

https://bastianfoundation.org/sites/default/files/cliente-atencion-guia-espanol.pdf

https://bastianfoundation.org/sites/default/files/cliente-atencion-guia-espanol-supporto.pdf

https://bastianfoundation.org/sites/default/files/cliente-atencion-guia-rapida-supporto.pdf

https://bastianfoundation.org/sites/default/files/cliente-atencion-guia-supporto.pdf

https://bastianfoundation.org/sites/default/files/cliente-atencion-supporto-espanol.pdf

https://bastianfoundation.org/sites/default/files/cliente-atencion-supporto-guia.pdf

https://bastianfoundation.org/sites/default/files/cliente-atencion-supporto-guia-rapida.pdf

https://bastianfoundation.org/sites/default/files/cliente-atencion-supporto-rapida.pdf

https://bastianfoundation.org/sites/default/files/cliente-ayuda.pdf

https://bastianfoundation.org/sites/default/files/cliente-ayuda-rapida-guia.pdf

https://bastianfoundation.org/sites/default/files/cliente-espanol-guia.pdf

https://bastianfoundation.org/sites/default/files/cliente-guia.pdf

https://bastianfoundation.org/sites/default/files/cliente-guia-atencion-al.pdf

https://bastianfoundation.org/sites/default/files/cliente-guia-atencion-supporto-espanol.pdf

https://bastianfoundation.org/sites/default/files/cliente-guia-ayuda-atencion-al.pdf

https://bastianfoundation.org/sites/default/files/cliente-guia-ayuda-espanol.pdf

https://bastianfoundation.org/sites/default/files/cliente-guia-ayuda-supporto-espanol.pdf

https://bastianfoundation.org/sites/default/files/cliente-guia-espanol-atencion.pdf

https://bastianfoundation.org/sites/default/files/cliente-guia-espanol-ayuda.pdf

https://bastianfoundation.org/sites/default/files/guia-espanol-atencion-al.pdf

https://bastianfoundation.org/sites/default/files/guia-espanol-atencion-cliente.pdf

https://bastianfoundation.org/sites/default/files/guia-espanol-cliente-atencion-supporto.pdf

https://bastianfoundation.org/sites/default/files/guia-espanol-cliente-supporto.pdf

https://bastianfoundation.org/sites/default/files/guia-espanol-rapida-supporto.pdf

https://bastianfoundation.org/sites/default/files/guia-espanol-supporto-ayuda.pdf

https://bastianfoundation.org/sites/default/files/guia-espanol-supporto-cliente-ayuda.pdf

https://bastianfoundation.org/sites/default/files/guia-rapida.pdf

https://bastianfoundation.org/sites/default/files/guia-rapida-atencion-al-supporto.pdf

https://bastianfoundation.org/sites/default/files/guia-rapida-ayuda.pdf

https://bastianfoundation.org/sites/default/files/espanol-guia-supporto-cliente.pdf

https://bastianfoundation.org/sites/default/files/espanol-guia-supporto-rapida-cliente.pdf

https://bastianfoundation.org/sites/default/files/espanol-rapida.pdf

https://bastianfoundation.org/sites/default/files/espanol-rapida-atencion-al-guia.pdf

https://bastianfoundation.org/sites/default/files/espanol-rapida-atencion-cliente.pdf

https://bastianfoundation.org/sites/default/files/espanol-rapida-atencion-supporto.pdf

https://bastianfoundation.org/sites/default/files/espanol-rapida-guia-atencion.pdf

https://bastianfoundation.org/sites/default/files/espanol-rapida-supporto.pdf

https://bastianfoundation.org/sites/default/files/espanol-rapida-supporto-atencion.pdf

https://bastianfoundation.org/sites/default/files/espanol-supporto.pdf

https://bastianfoundation.org/sites/default/files/espanol-supporto-atencion.pdf

https://bastianfoundation.org/sites/default/files/espanol-supporto-guia-ayuda.pdf

https://bastianfoundation.org/sites/default/files/espanol-supporto-guia-cliente-ayuda.pdf

https://bastianfoundation.org/sites/default/files/espanol-supporto-rapida-guia.pdf

https://bastianfoundation.org/sites/default/files/guia-al-cliente.pdf

https://bastianfoundation.org/sites/default/files/guia-atencion.pdf

https://bastianfoundation.org/sites/default/files/guia-atencion-al-cliente-supporto.pdf

https://bastianfoundation.org/sites/default/files/guia-ayuda.pdf

https://bastianfoundation.org/sites/default/files/guia-ayuda-atencion-supporto-cliente.pdf

https://bastianfoundation.org/sites/default/files/guia-ayuda-rapida-supporto.pdf

https://bastianfoundation.org/sites/default/files/espanol-guia-ayuda-atencion-cliente.pdf

https://bastianfoundation.org/sites/default/files/espanol-guia-ayuda-rapida-supporto.pdf

https://bastianfoundation.org/sites/default/files/espanol-guia-cliente-ayuda-rapida.pdf

https://bastianfoundation.org/sites/default/files/espanol-guia-cliente-rapida.pdf

https://bastianfoundation.org/sites/default/files/espanol-guia-cliente-supporto.pdf

https://bastianfoundation.org/sites/default/files/espanol-guia-rapida.pdf

https://bastianfoundation.org/sites/default/files/espanol-guia-rapida-atencion-cliente.pdf

https://bastianfoundation.org/sites/default/files/espanol-guia-rapida-cliente.pdf

https://bastianfoundation.org/sites/default/files/espanol-guia-rapida-supporto-atencion.pdf

https://bastianfoundation.org/sites/default/files/espanol-guia-supporto-ayuda.pdf

https://bastianfoundation.org/sites/default/files/guia-rapida-ayuda-atencion-supporto.pdf

https://bastianfoundation.org/sites/default/files/guia-rapida-ayuda-supporto-atencion.pdf

https://bastianfoundation.org/sites/default/files/guia-rapida-cliente-supporto.pdf

https://bastianfoundation.org/sites/default/files/guia-rapida-supporto-atencion-al.pdf

https://bastianfoundation.org/sites/default/files/guia-rapida-supporto-ayuda.pdf

https://bastianfoundation.org/sites/default/files/guia-rapida-supporto-ayuda-cliente.pdf

https://bastianfoundation.org/sites/default/files/guia-supporto-atencion-al-cliente.pdf

https://bastianfoundation.org/sites/default/files/guia-supporto-ayuda-cliente-atencion.pdf

https://bastianfoundation.org/sites/default/files/guia-supporto-cliente.pdf

https://bastianfoundation.org/sites/default/files/guia-supporto-rapida.pdf

https://bastianfoundation.org/sites/default/files/espanol-ayuda.pdf

https://bastianfoundation.org/sites/default/files/espanol-ayuda-atencion-supporto.pdf

https://bastianfoundation.org/sites/default/files/espanol-ayuda-rapida.pdf

https://bastianfoundation.org/sites/default/files/espanol-cliente-atencion.pdf

https://bastianfoundation.org/sites/default/files/espanol-cliente-atencion-guia-rapida.pdf

https://bastianfoundation.org/sites/default/files/espanol-cliente-guia-rapida.pdf

https://bastianfoundation.org/sites/default/files/espanol-cliente-guia-supporto.pdf

https://bastianfoundation.org/sites/default/files/espanol-cliente-supporto-rapida.pdf

https://bastianfoundation.org/sites/default/files/espanol-guia.pdf

https://bastianfoundation.org/sites/default/files/espanol-guia-ayuda.pdf

https://bastianfoundation.org/sites/default/files/guia-ayuda-supporto-cliente-atencion.pdf

https://bastianfoundation.org/sites/default/files/guia-ayuda-supporto-rapida.pdf

https://bastianfoundation.org/sites/default/files/guia-cliente.pdf

https://bastianfoundation.org/sites/default/files/guia-cliente-atencion-al-supporto.pdf

https://bastianfoundation.org/sites/default/files/guia-cliente-ayuda.pdf

https://bastianfoundation.org/sites/default/files/guia-cliente-ayuda-supporto-rapida.pdf

https://bastianfoundation.org/sites/default/files/guia-cliente-rapida-ayuda.pdf

https://bastianfoundation.org/sites/default/files/guia-cliente-supporto-atencion-al.pdf

https://bastianfoundation.org/sites/default/files/guia-cliente-supporto-ayuda-rapida.pdf

https://bastianfoundation.org/sites/default/files/guia-espanol.pdf

https://bastianfoundation.org/sites/default/files/cliente-supporto-ayuda-rapida.pdf

https://bastianfoundation.org/sites/default/files/cliente-supporto-guia-ayuda.pdf

https://bastianfoundation.org/sites/default/files/cliente-supporto-guia-cliente.pdf

https://bastianfoundation.org/sites/default/files/cliente-supporto-rapida.pdf

https://bastianfoundation.org/sites/default/files/espanol-atencion-al.pdf

https://bastianfoundation.org/sites/default/files/espanol-atencion-cliente.pdf

https://bastianfoundation.org/sites/default/files/espanol-atencion-cliente-supporto.pdf

https://bastianfoundation.org/sites/default/files/espanol-atencion-guia-supporto-rapida.pdf

https://bastianfoundation.org/sites/default/files/espanol-atencion-rapida-guia.pdf

https://bastianfoundation.org/sites/default/files/espanol-atencion-supporto-cliente.pdf

https://bastianfoundation.org/sites/default/files/cliente-guia-rapida.pdf

https://bastianfoundation.org/sites/default/files/cliente-guia-rapida-ayuda-supporto.pdf

https://bastianfoundation.org/sites/default/files/cliente-guia-rapida-supporto-atencion.pdf

https://bastianfoundation.org/sites/default/files/cliente-guia-supporto.pdf

https://bastianfoundation.org/sites/default/files/cliente-guia-supporto-espanol-rapida.pdf

https://bastianfoundation.org/sites/default/files/cliente-guia-supporto-rapida.pdf

https://bastianfoundation.org/sites/default/files/cliente-rapida.pdf

https://bastianfoundation.org/sites/default/files/cliente-supporto.pdf

https://bastianfoundation.org/sites/default/files/cliente-supporto-atencion-al.pdf

https://bastianfoundation.org/sites/default/files/cliente-supporto-ayuda-atencion.pdf

https://bastianfoundation.org/sites/default/files/guia-supporto-rapida-ayuda-atencion.pdf

https://bastianfoundation.org/sites/default/files/rapida-atencion.pdf

https://bastianfoundation.org/sites/default/files/rapida-atencion-al-guia.pdf

https://bastianfoundation.org/sites/default/files/rapida-atencion-al-guia-supporto.pdf

https://bastianfoundation.org/sites/default/files/rapida-atencion-guia-cliente.pdf

https://bastianfoundation.org/sites/default/files/rapida-atencion-guia-espanol-ayuda.pdf

https://bastianfoundation.org/sites/default/files/rapida-ayuda.pdf

https://bastianfoundation.org/sites/default/files/rapida-ayuda-atencion.pdf

https://bastianfoundation.org/sites/default/files/rapida-ayuda-cliente.pdf

https://bastianfoundation.org/sites/default/files/rapida-ayuda-cliente-espanol.pdf

https://bastianfoundation.org/sites/default/files/rapida-ayuda-espanol-guia.pdf

https://bastianfoundation.org/sites/default/files/rapida-ayuda-guia-espanol.pdf

https://bastianfoundation.org/sites/default/files/rapida-cliente.pdf

https://bastianfoundation.org/sites/default/files/rapida-cliente-atencion.pdf

https://bastianfoundation.org/sites/default/files/rapida-cliente-atencion-al-guia.pdf

https://bastianfoundation.org/sites/default/files/rapida-cliente-atencion-guia.pdf

https://bastianfoundation.org/sites/default/files/rapida-cliente-atencion-supporto.pdf

https://bastianfoundation.org/sites/default/files/rapida-cliente-espanol-guia.pdf

https://bastianfoundation.org/sites/default/files/rapida-cliente-guia-espanol.pdf

https://bastianfoundation.org/sites/default/files/rapida-cliente-guia-supporto.pdf

https://bastianfoundation.org/sites/default/files/rapida-cliente-supporto.pdf

https://bastianfoundation.org/sites/default/files/rapida-cliente-supporto-guia-ayuda.pdf

https://bastianfoundation.org/sites/default/files/rapida-espanol.pdf

https://bastianfoundation.org/sites/default/files/rapida-guia.pdf

https://bastianfoundation.org/sites/default/files/rapida-guia-atencion-al.pdf

https://bastianfoundation.org/sites/default/files/rapida-guia-atencion-cliente.pdf

https://bastianfoundation.org/sites/default/files/rapida-guia-atencion-supporto.pdf

https://bastianfoundation.org/sites/default/files/rapida-guia-ayuda-cliente.pdf

https://bastianfoundation.org/sites/default/files/rapida-guia-cliente-atencion-al.pdf

https://bastianfoundation.org/sites/default/files/rapida-guia-cliente-supporto.pdf

https://bastianfoundation.org/sites/default/files/soporte-guia-rapida-espanol.pdf

https://bastianfoundation.org/sites/default/files/soporte-rapida-atencion.pdf

https://bastianfoundation.org/sites/default/files/soporte-rapida-atencion-cliente-guia.pdf

https://bastianfoundation.org/sites/default/files/soporte-rapida-atencion-guia.pdf

https://bastianfoundation.org/sites/default/files/soporte-rapida-cliente-espanol.pdf

https://bastianfoundation.org/sites/default/files/soporte-rapida-cliente-guia-supporto.pdf

https://bastianfoundation.org/sites/default/files/soporte-rapida-guia-ayuda.pdf

https://bastianfoundation.org/sites/default/files/soporte-rapida-guia-cliente.pdf

https://bastianfoundation.org/sites/default/files/supporto-atencion.pdf

https://bastianfoundation.org/sites/default/files/supporto-cliente.pdf

https://bastianfoundation.org/sites/default/files/soporte-espanol-guia.pdf

https://bastianfoundation.org/sites/default/files/soporte-espanol-guia-atencion.pdf

https://bastianfoundation.org/sites/default/files/soporte-guia-atencion-al-rapida.pdf

https://bastianfoundation.org/sites/default/files/soporte-guia-ayuda-rapida.pdf

https://bastianfoundation.org/sites/default/files/soporte-guia-cliente-atencion.pdf

https://bastianfoundation.org/sites/default/files/soporte-guia-cliente-rapida.pdf

https://bastianfoundation.org/sites/default/files/soporte-guia-espanol.pdf

https://bastianfoundation.org/sites/default/files/soporte-guia-espanol-rapida.pdf

https://bastianfoundation.org/sites/default/files/soporte-guia-rapida-cliente-espanol.pdf

https://bastianfoundation.org/sites/default/files/supporto-guia.pdf

https://bastianfoundation.org/sites/default/files/soporte-ayuda-cliente-guia.pdf

https://bastianfoundation.org/sites/default/files/soporte-ayuda-espanol-atencion.pdf

https://bastianfoundation.org/sites/default/files/soporte-ayuda-rapida-atencion.pdf

https://bastianfoundation.org/sites/default/files/soporte-cliente-atencion-al.pdf

https://bastianfoundation.org/sites/default/files/soporte-cliente-espanol-guia.pdf

https://bastianfoundation.org/sites/default/files/soporte-cliente-espanol-guia-rapida.pdf

https://bastianfoundation.org/sites/default/files/soporte-cliente-guia.pdf

https://bastianfoundation.org/sites/default/files/soporte-cliente-guia-espanol-rapida.pdf

https://bastianfoundation.org/sites/default/files/soporte-cliente-rapida-guia.pdf

https://bastianfoundation.org/sites/default/files/soporte-espanol-atencion-guia.pdf

https://bastianfoundation.org/sites/default/files/rapida-supporto-espanol-cliente.pdf

https://bastianfoundation.org/sites/default/files/rapida-supporto-espanol-guia-cliente.pdf

https://bastianfoundation.org/sites/default/files/rapida-supporto-guia.pdf

https://bastianfoundation.org/sites/default/files/rapida-supporto-guia-ayuda.pdf

https://bastianfoundation.org/sites/default/files/soporte-atencion-al.pdf

https://bastianfoundation.org/sites/default/files/soporte-atencion-al-espanol.pdf

https://bastianfoundation.org/sites/default/files/soporte-atencion-cliente-guia-espanol.pdf

https://bastianfoundation.org/sites/default/files/soporte-atencion-guia.pdf

https://bastianfoundation.org/sites/default/files/soporte-atencion-guia-cliente-espanol.pdf

https://bastianfoundation.org/sites/default/files/soporte-atencion-guia-espanol.pdf

https://bastianfoundation.org/sites/default/files/rapida-guia-supporto-espanol.pdf

https://bastianfoundation.org/sites/default/files/rapida-guia-supporto-espanol-ayuda.pdf

https://bastianfoundation.org/sites/default/files/rapida-supporto.pdf

https://bastianfoundation.org/sites/default/files/rapida-supporto-atencion-cliente.pdf

https://bastianfoundation.org/sites/default/files/rapida-supporto-atencion-guia-espanol.pdf

https://bastianfoundation.org/sites/default/files/rapida-supporto-ayuda-espanol.pdf

https://bastianfoundation.org/sites/default/files/rapida-supporto-cliente-atencion.pdf

https://bastianfoundation.org/sites/default/files/rapida-supporto-cliente-atencion-al.pdf

https://bastianfoundation.org/sites/default/files/soporte-atencion-rapida.pdf

https://bastianfoundation.org/sites/default/files/supporto-guia-rapida.pdf

https://bastianfoundation.org/sites/default/files/rapida-guia-espanol.pdf

https://bastianfoundation.org/sites/default/files/rapida-guia-espanol-ayuda.pdf

https://bastianfoundation.org/sites/default/files/rapida-guia-supporto-cliente-espanol.pdf