Finding the perfect shoe insole can be challenging because everyone's feet are unique. Whether you're dealing with flat feet, high arches, or just want better comfort, custom insoles can make a significant difference. In this guide, we'll show you how to create personalized insoles using 3D printing technology - a cost-effective and customizable solution for your comfort needs.

Why 3D Print Custom Insoles?

- Personalized fit for your unique foot shape

- Cost-effective compared to commercial custom orthotics

- Easy modifications for different comfort levels

- Quick replacements when needed

- Breathable designs for better foot health

Essential Materials and Equipment

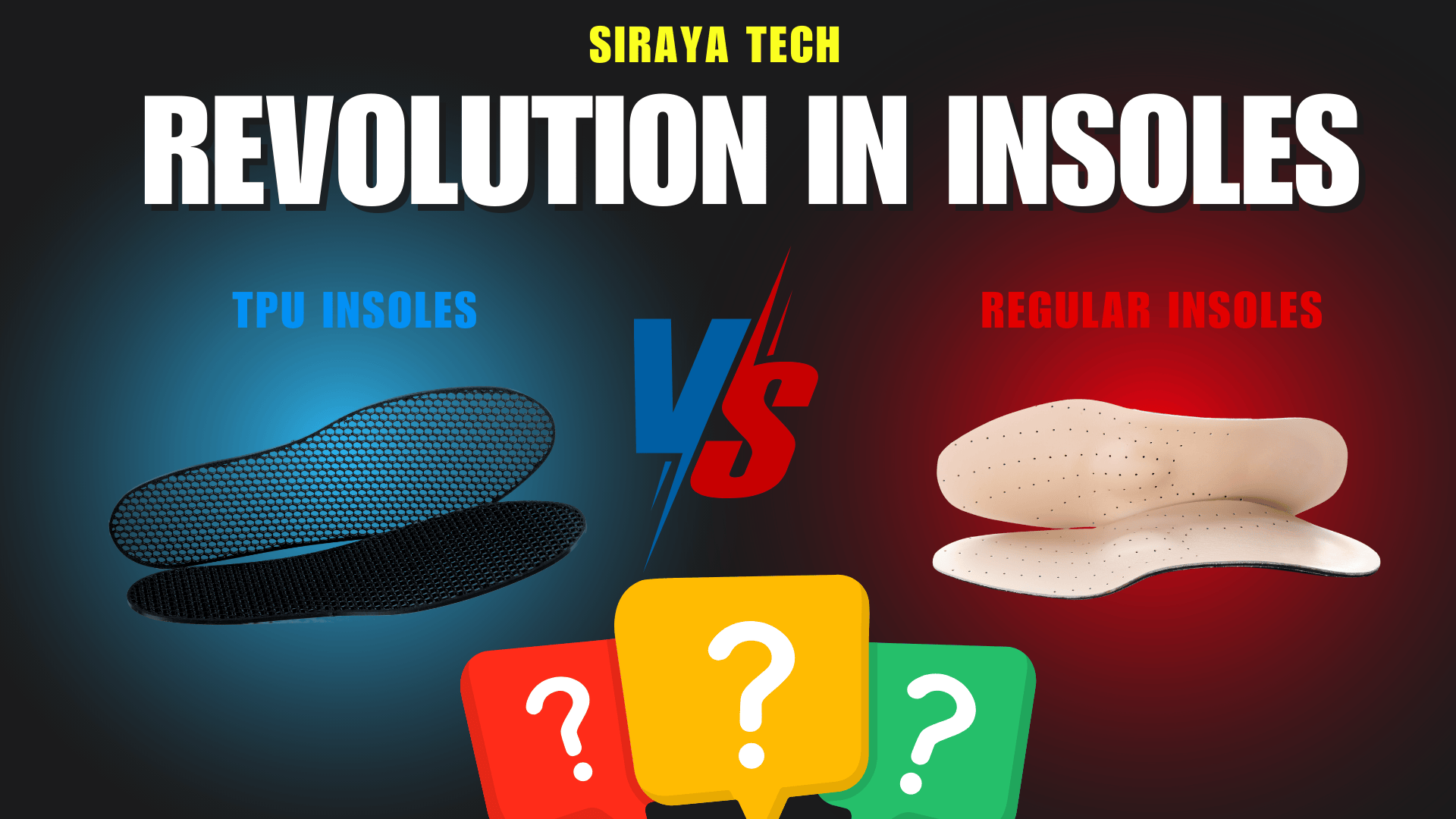

The Right Material: TPU Filament

For comfortable and durable insoles, Thermoplastic Polyurethane (TPU) is the ideal material. We recommend using either:

- TPU 95A: Offers firmer support while maintaining flexibility

- TPU 85A: Provides softer cushioning for maximum comfort

Both options are ISO 10993 tested, ensuring safety for skin contact and wearable applications. These materials offer excellent durability and maintain their properties over extended use.

Printer Requirements

For successful insole printing, you'll need:

- An FDM 3D printer with direct drive extruder

- Minimum build plate size: 250 x 250mm (larger for bigger shoe sizes)

- Direct filament feeding capability (avoid AMS or filament changing systems)

Recommended Printer: The Bambu Labs A1 is an excellent choice for this project, offering the perfect combination of features for TPU printing.

Finding the Right Model

You can source insole models from various 3D printing communities:

- Makerworld

- MyMiniFactory

- Printables

- Thingiverse

For our initial test, we used this model from Makerworld.

Our Testing Process and Findings

Initial Print Settings

During our testing, we made several important discoveries:

1. Thickness Matters:

- Original 3mm thickness was too rigid

- Reduced to 1mm for better comfort

- Consider your personal preference when adjusting thickness

2. Size Adjustments:

- Scale the model to match your foot size

- Test fit before final printing

- Make incremental adjustments as needed

3. Design Considerations:

- Honeycomb infill pattern created holes too large for optimal comfort

- Structure was slightly too rigid for extended wear

- Consider alternative infill patterns for better weight distribution

Initial Results and Future Plans

Our first attempts provided valuable insights:

- Better breathability compared to standard insoles

- Good cushioning effect

- Need for optimization in infill patterns

- Opportunity for design improvements

We're continuing to test and optimize the process to find the perfect balance of comfort, support, and durability. Stay tuned for future updates where we'll explore:

- Alternative infill patterns

- Different thickness combinations

- Custom support structures

- Material mixing ratios

Next Steps

In upcoming blog posts, we'll dive deeper into:

- Advanced customization techniques

- Optimizing print settings

- Material combinations for different needs

- Different Printing Process

Subscribe to our blog for future updates and detailed guides on creating the perfect custom insoles for your needs.

1 comment

JoseL Campuzano

Looking for Gucci foamposite sole replacement size 9.5