When working with PAHT-CF (PPA-CF) filament, you might notice an interesting phenomenon - different colors appearing within the same print, even when using a single-color filament. This effect, while potentially striking, usually indicates an underlying temperature management issue that needs addressing.

Understanding the Problem

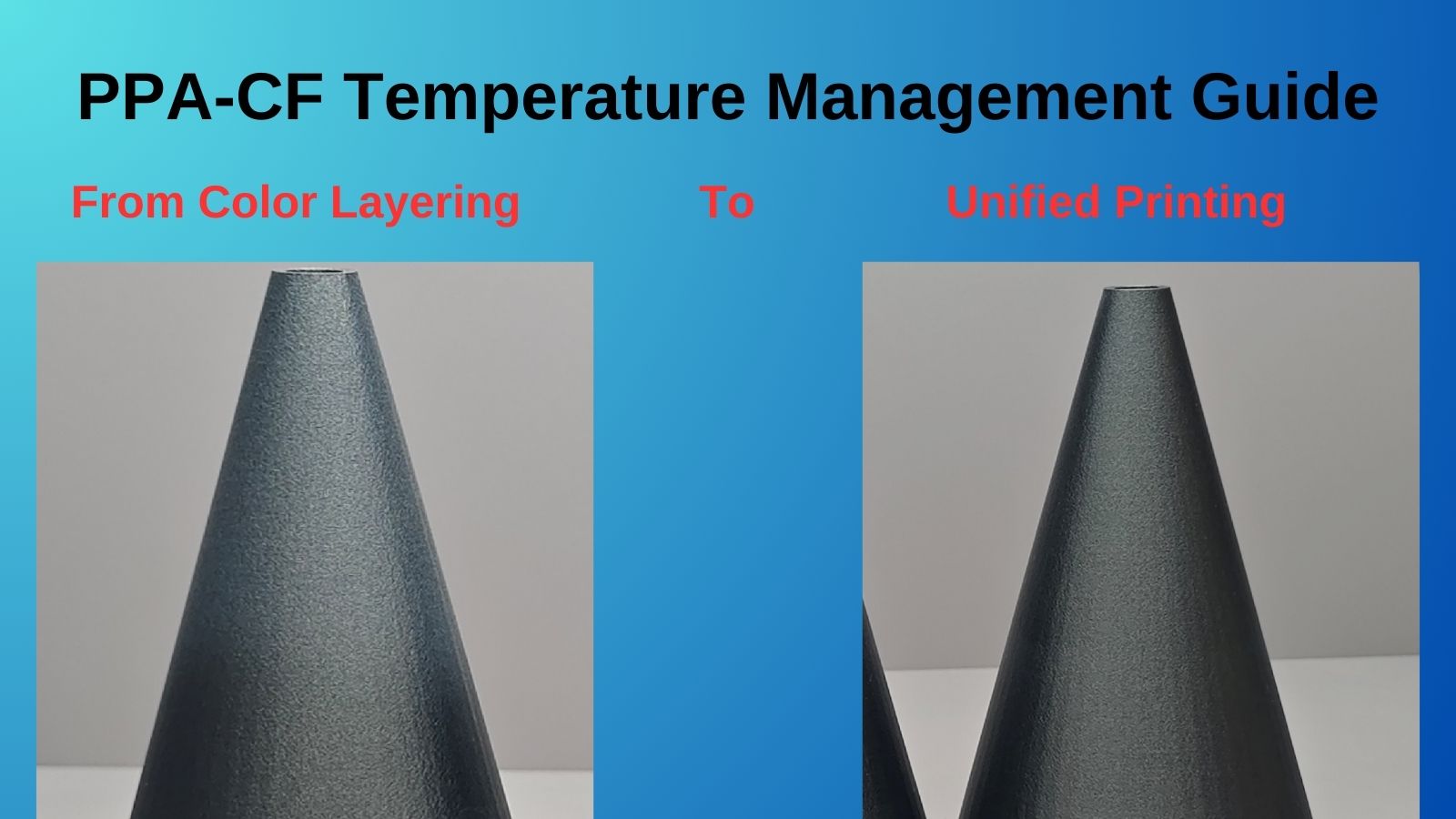

In the demonstration images, we can see three identical cone prints showing different surface appearances. The key variable between these prints is the cooling fan settings.

The leftmost print, with the fan completely off, shows a notably different surface color compared to the others, highlighting how thermal conditions directly impact the material's appearance.

The Root Cause

These color variations occur primarily due to temperature differences during printing.

When layer times are too short, the material doesn't have sufficient time to cool before the next layer is deposited. This inconsistent cooling leads to varying crystallization rates in the polymer, resulting in visible color differences across the print.

The Solution

Strategic Fan Speed Control Our testing revealed that proper fan speed management can effectively address this issue. Here's what worked in Bambu Lab X1C.

For optimal results, we implemented a dual-threshold fan speed strategy:

- Minimum fan speed: 10% with a layer time of 10 seconds

- Maximum fan speed: 25% with a layer time of 7 seconds

This combination provided consistent cooling across the print, resulting in uniform color appearance, as marked "GOOD" in our test prints.

Implementation Tips

- Start with a minimum fan speed threshold of 10% for layers taking 10 seconds or longer.

- Increase fan speed to 25% when layer times drop below 7 seconds.

- Monitor the first few layers carefully to ensure proper adhesion.

- Maintain consistent speed settings throughout similar geometries.

By carefully managing these cooling parameters, you can achieve consistent color appearance across your PAHT-CF prints, ensuring both aesthetic quality and structural integrity.

- Remember: These settings serve as a starting point and might need fine-tuning based on your specific printer setup and environmental conditions.

Have you experienced color variations in your PAHT-CF prints? What cooling strategies have worked for you?