Description

Features of Flex 85A TPU

- Enhanced Flexibility: Compared to common 95A TPU filaments, Flex 85A offers superior flexibility, making it an ideal choice for wearable devices and flexible parts.

- Excellent Impact Resistance: This filament boasts outstanding impact resistance, suitable for printing projects that require high durability and toughness.

- Ease of Printing: Flex 85A is specially formulated to extrude more easily and adhere better, ensuring a smoother printing process compatible with various printer models.

- 5x High-Speed Printing Performance: It can print up to 5 times faster than comparable TPU filaments while maintaining high-quality print results.

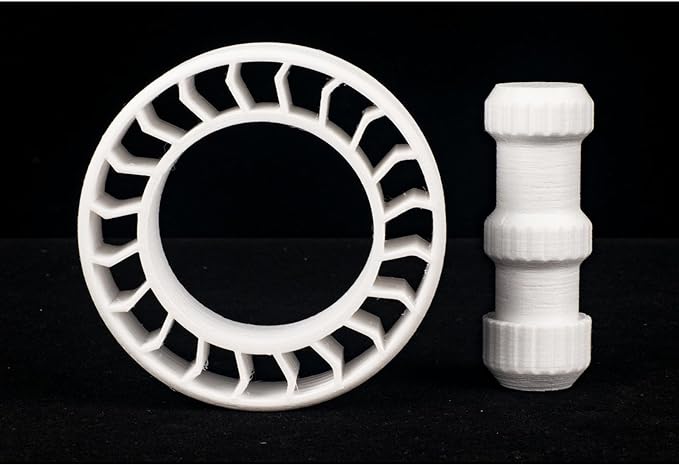

Applications of Flex 85A TPU

- Wearable Devices: Such as straps for smartwatches, fitness tracker bands, etc.

- Flexible Connectors: Like hoses, vibration dampening pads, etc.

- Prototyping: The fast printing capability makes it ideal for design prototyping and rapid iteration.

- Medical Device Accessories: Custom wrist braces, supports, etc., requiring materials that are both comfortable and durable.

- Everyday Items: Phone cases, shock-absorbing pads, protective covers, and more.

Why choose Siraya Tech 85A Filament?

Flex TPU -- 85A Shore hardness. Come with Black and While!

High Flow, High Speed

Designed for high-flow, Flex TPU 85A filament enables quicker prints than typical TPU 95a, blending speed with stellar outcomes.

For the optimal printing experience, we recommend using a direct drive style extruder.

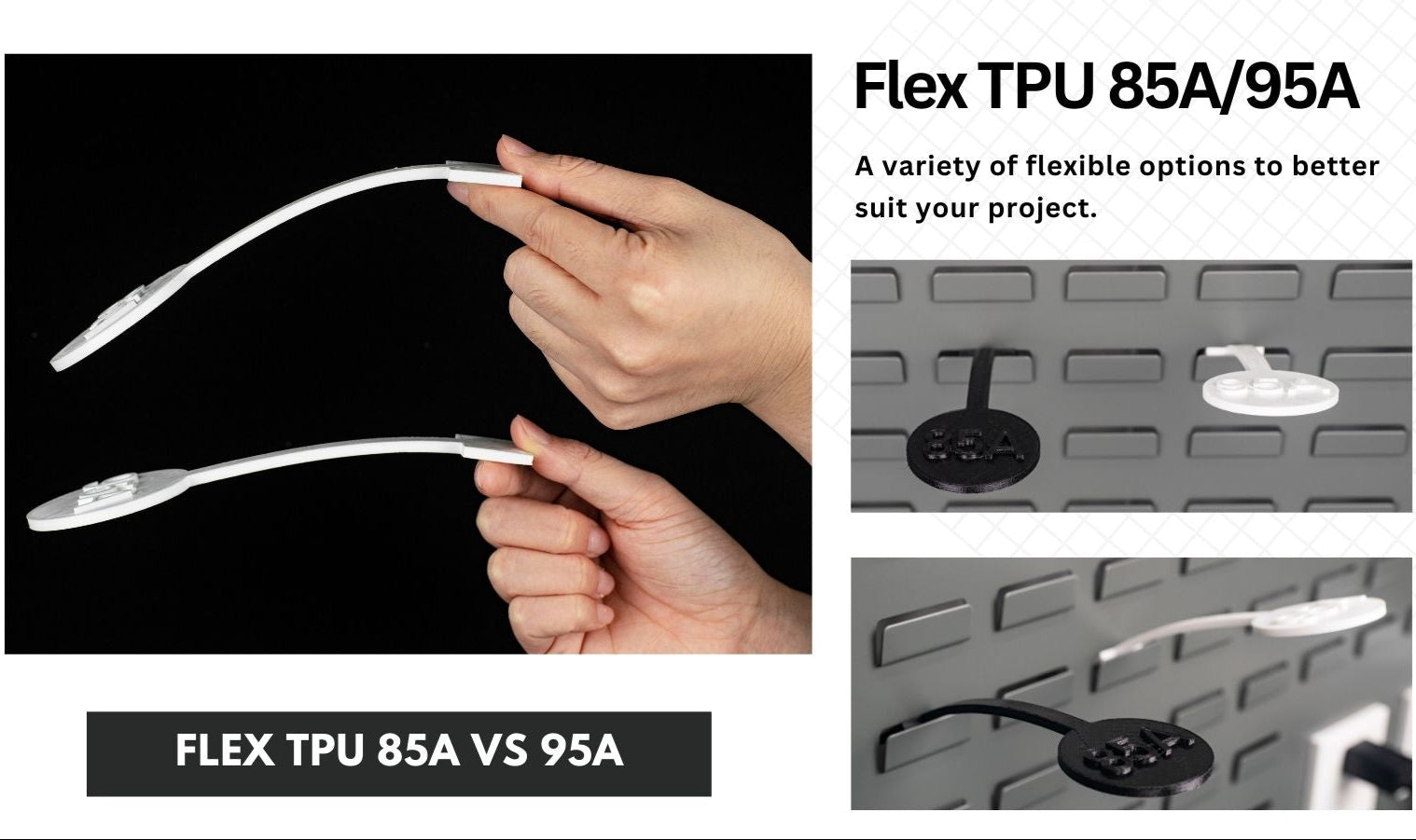

Superior Flexibility & Toughness

Siraya Tech's Flex TPU 85A 3d printer filament excels in flexibility and elasticity, making it ideal for durable, bendable 3D prints. Perfect for softer, pliable projects.

Softer feel, Flexible than 95A

85A is more flexible and softer than 95A, making it more suitable for wearable applications. Use 85A for a softer wearable experience.

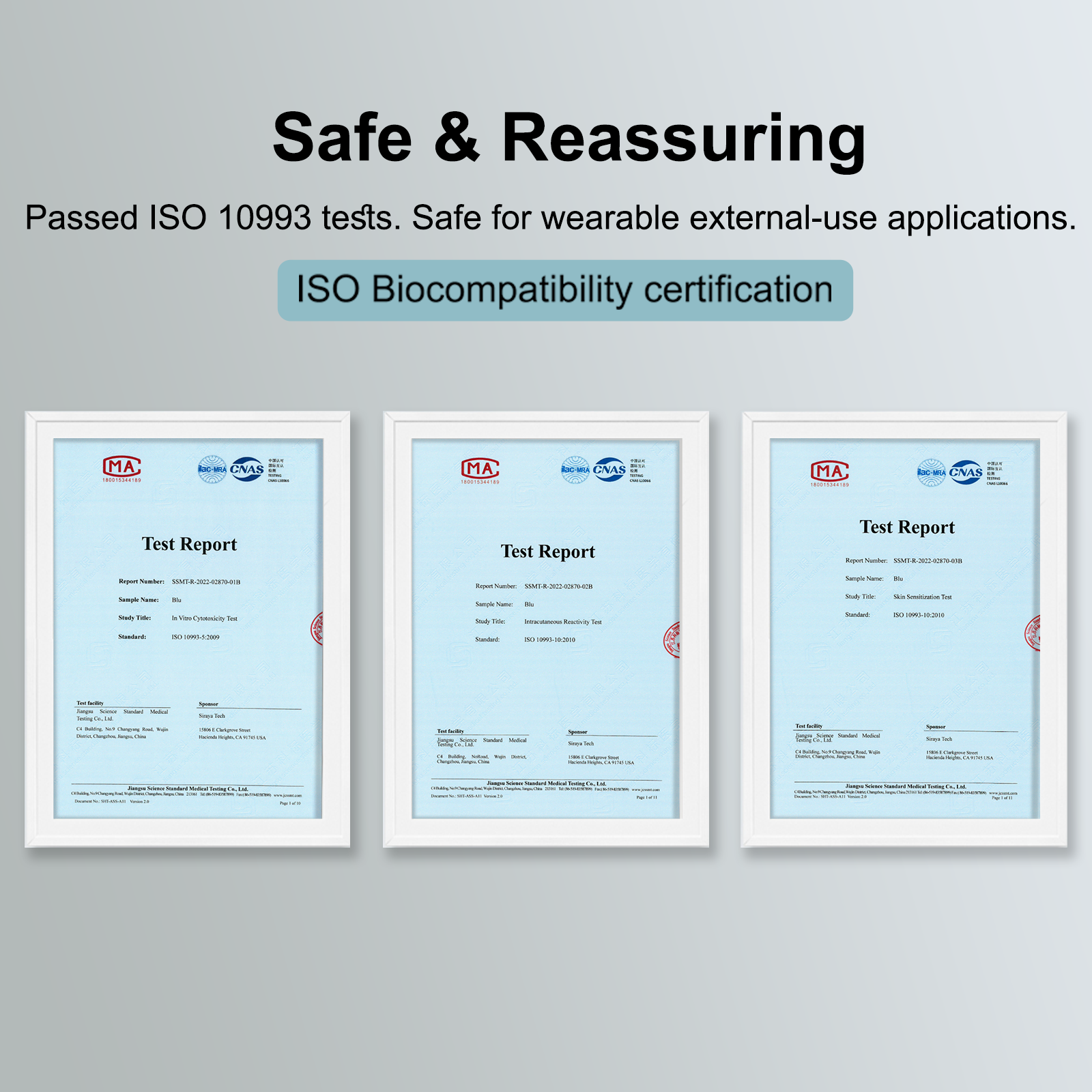

Safe and reliable - Biocompatibility Certification

TPU Flex Filament has passed the ISO 10993-5, ISO 10993-10, and ISO 10993-23 certifications for skin contact.

These tests evaluate biological responses to materials, providing data on potential biocompatibility.

This testing helps ensure peace of mind when printing for external-use wearables and devices.

What makes Flex TPU different?

Up to 5x speed

Compared with similar TPU filaments, the material of Flex TPU has been upgraded, making it easier to extrude and the printing speed can be increased by 5X.

Further moisture protection

Use vacuum aluminum-based packaging, which is more moisture-proof than ordinary transparent bags. And the sealing strip allows reinstallation after removal.

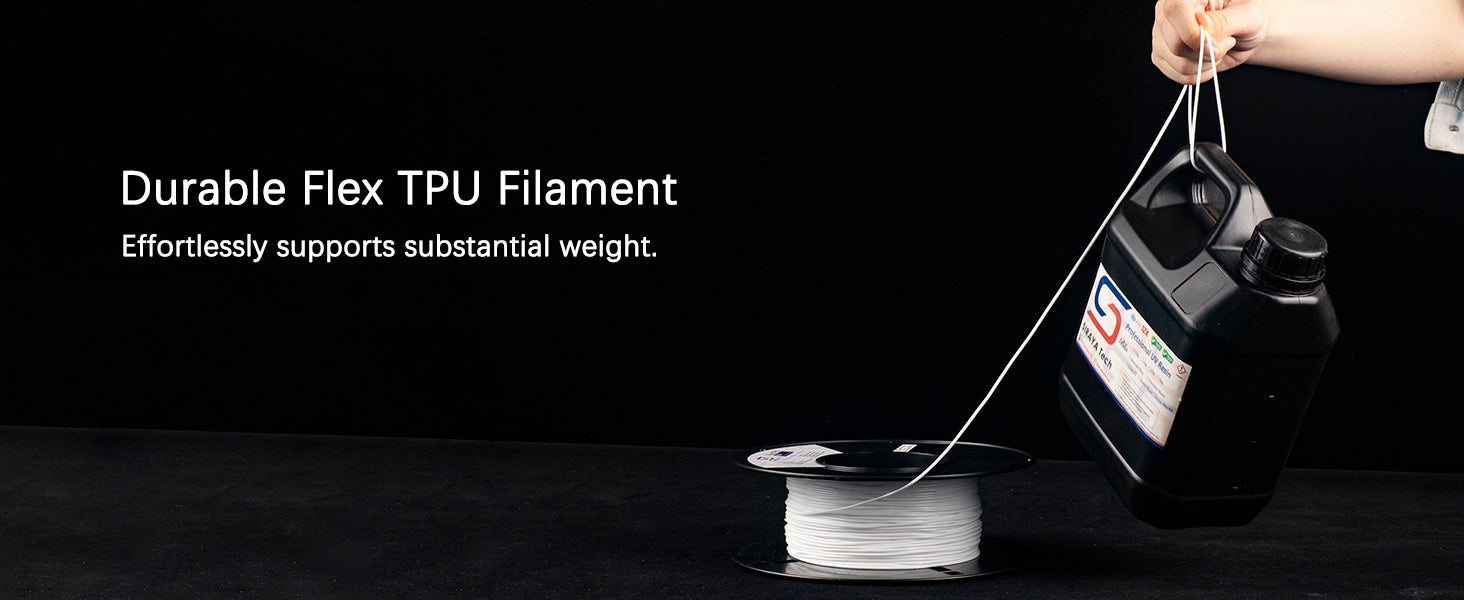

Flex TPU Filament is stronger and more durable

The material has been upgraded, and the filament has strong toughness and can easily lift heavy objects.

Prints feel softer to the touch

The printed surface is clean and smooth, and the Shore hardness of 85A gives filament printing a soft feel closer to silicone.

Preparing for Printing

(1) Printer Compatibility

- Flex TPU 85A is optimized for FDM printers equipped with direct drive extruders, which are located on the toolhead for enhanced filament control. This setup is crucial for successful TPU printing.

- For best results, mount the filament directly above the extruder to facilitate the shortest and most efficient path from the spool to the extruder, thus significantly enhancing the print quality and success rate.

(2) Print Bed Preparation

A clean, level print bed is essential. We recommend a heated bed temperature ranging from 20°C to 50°C, adjusted according to your printer’s capabilities.

Siraya Tech Flex TPU Prints showcase