Recently viewed

PPA filament from Siraya Tech is built for creators who want to make parts that go beyond ordinary nylon. This collection of high-performance filaments combines the strength and heat resistance of engineering-grade polymers with the precision and reliability that modern makers need.

With low moisture absorption, superior layer adhesion, and excellent thermal resistance, you can confidently print parts that stay strong even under stress.

Get Strength and Stability that Last with PPA Filament

PPA filament gives you the power to create parts that stay strong and accurate, even in extreme conditions.

Built for High-Stress Performance

- Withstands heat and pressure without losing shape or strength.

- Ideal for automotive, aerospace, and industrial parts.

- Maintains its mechanical properties under continuous load and heat.

Dimensional Accuracy You Can Trust

- Low moisture absorption keeps prints consistent and warp-free.

- Perfect for tight-tolerance parts and assemblies.

- Produces smooth, clean finishes that need minimal post-processing.

Print with Confidence Every Time

These filaments are designed for creators who want dependable results with every print.

Easy, Stable, and Reliable Printing

- Optimized for enclosed, high-temperature FDM printers.

- Works best with hardened steel nozzles (0.4mm or larger).

- Prints beautifully with consistent layer bonding and minimal warping.

Simple to Handle and Maintain

- Low hygroscopic properties mean less drying time.

- Easy to store—just keep it sealed or in a dry box.

- Compatible with PEI or PVP-coated beds for great adhesion.

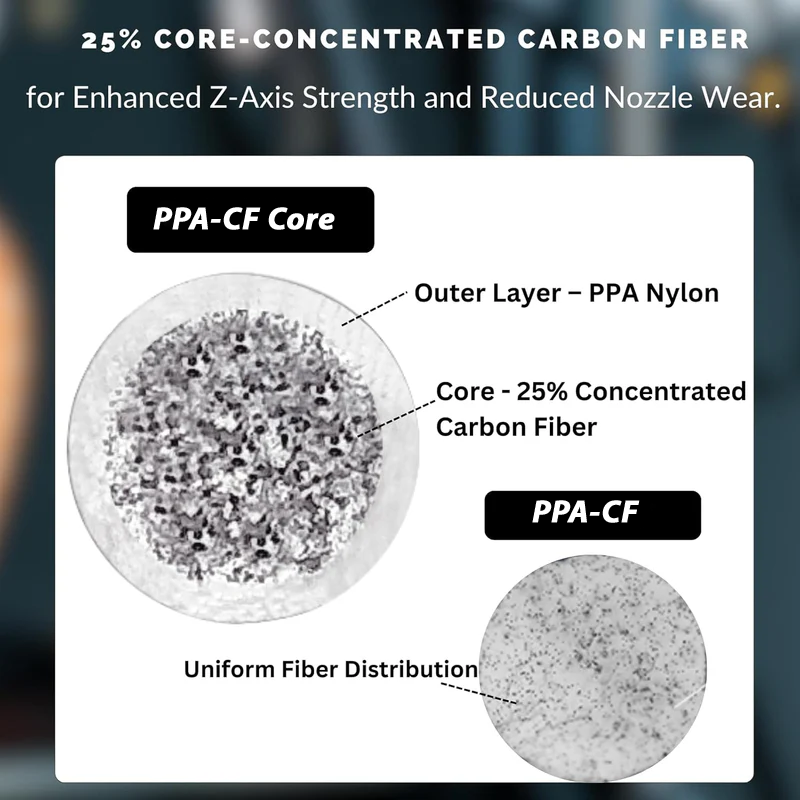

Carbon Fiber Reinforcement for Next-Level Performance

When you need more than just strength, carbon fiber-infused PPA filaments take it further.

Lightweight Yet Incredibly Strong

- Carbon fibers create a rigid internal structure for added stiffness.

- Reduces part weight while increasing durability and resistance to wear.

- Ideal for mechanical parts, brackets, and load-bearing components.

Designed for Long-Term Use

- Carbon fiber reduces warping and improves heat tolerance.

- Protective outer layers minimize nozzle wear.

- Produces professional-grade parts with a refined matte finish.

Perfect for Makers Who Demand More

PPA filament isn’t just for industrial engineers—it’s for every creator who wants to build parts that perform.

Why Makers Love It

- Exceptional chemical and abrasion resistance.

- Smooth extrusion and consistent layer bonding.

- Great for functional prototypes, gears, and fixtures.

Explore More Collections You’ll Love

- Carbon Fiber Filament– Print ultra-strong, lightweight parts that resist heat and wear.

- Nylon Filaments– Flexible, durable, and perfect for engineering-grade prints.

- FDM Filament– Reliable materials built for precision printing on all FDM machines.

- 1.75mm Filament – Consistent diameter and smooth flow for clean, accurate results.

FAQs on PPA Filament

What is PPA filament?

PPA filament, or Polyphthalamide filament, is a high-performance nylon used in 3D printing for parts that need superior heat and chemical resistance.

It offers greater strength and dimensional stability than standard PA6 or PA12 nylons. This makes it ideal for demanding applications like automotive, aerospace, and industrial components.

What temperature is PPA printing?

PPA filament typically prints at high temperatures between 280°C and 320°C, depending on the specific blend.

The bed temperature is usually around 80–120°C to ensure proper adhesion. Because of these high printing temperatures, an all-metal hotend and an enclosed printer are recommended for best results.

How durable is PPA-CF?

PPA-CF, or carbon fiber-reinforced PPA, is extremely durable and stiff. The carbon fibers create a strong internal structure that resists warping, heat, and mechanical stress.

It’s perfect for functional parts that require low weight and high strength, such as brackets, fixtures, and mechanical assemblies.

What does PPA stand for in 3D printing?

PPA stands for Polyphthalamide, a type of high-temperature nylon known for its exceptional mechanical and thermal properties.

In 3D printing, it’s valued for its ability to maintain shape and strength under heat and stress, making it a go-to material for professional and industrial applications.