3D printed walls are changing how we build homes and structures. Instead of traditional bricks or wood, these walls are created using large 3D printers that layer materials like concrete to form sturdy walls.

This innovative method is faster, often cheaper, and allows for unique designs that were hard to achieve before.

If you want to learn how 3d printed walls work and why they matter, keep reading to discover the key facts and benefits.

What Is a 3D Printed Wall and How Does It Work?

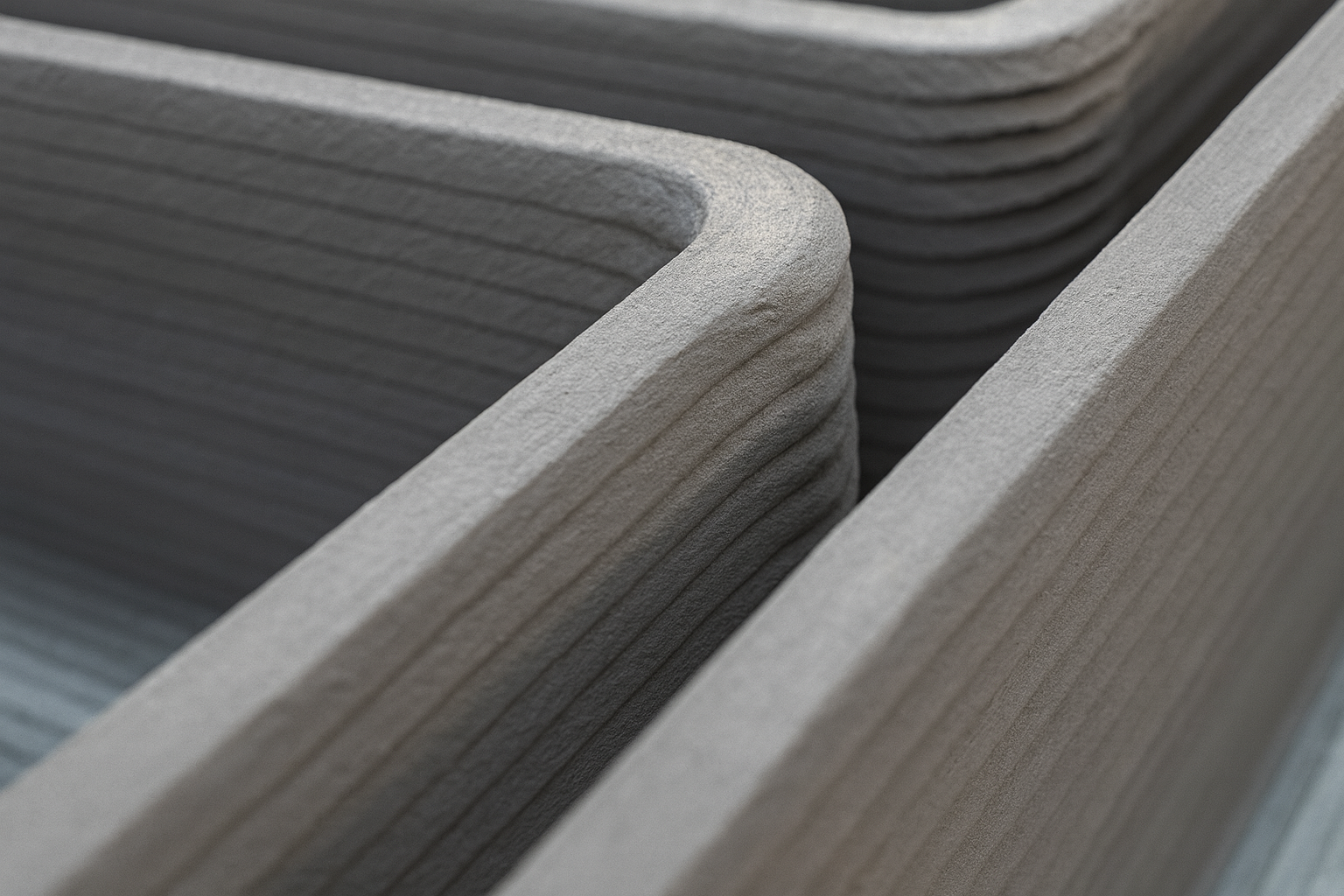

A 3d printed wall is a wall made by a special kind of printer that builds the wall layer by layer. Instead of ink, these printers use materials like concrete or other strong mixtures. The printer follows a digital design to create the wall exactly as planned.

This process is different from traditional building because it does not need as many workers or tools. The printer can create complex shapes and textures that would be hard to do by hand. Materials used for 3d printed walls include:

- Concrete mixes designed for quick drying

- Composite materials for added strength

- Sometimes recycled or eco-friendly substances

📌 If you want to explore more about what you can create with 3D printing, check out the article titled What Can You Make With a 3D Printer? for inspiring ideas.

Benefits of 3D Printed Walls Compared to Traditional Walls

3d printed walls offer many advantages that make them interesting for builders and homeowners. One big benefit is speed. These walls can be printed much faster than they can be built with bricks or wood. This means construction projects can finish sooner.

Another benefit is cost savings. Since fewer workers and less material waste are needed, the overall cost goes down. Plus, 3d printing allows for unique designs that are hard to create with normal building methods. Some other benefits include:

- Less waste during construction, helping the environment

- Ability to customize walls with different textures or shapes

- More precise building, reducing errors

When it comes to materials for 3d printed walls or decorative panels, specialty filaments can make a difference.

For example, Siraya offers PETG-CF, a carbon fiber-infused filament that shares many properties with standard PETG but adds a matte finish, greater hardness, and less warping. This filament is ideal for strong, custom wall panels or accents rather than full structural walls.

Siraya Products You May Want to Shop

Explore More📌 If you want to learn about useful things you can 3d print beyond walls, don’t forget to browse the article Useful Things to 3D Print for Everyday Life for practical ideas.

How Strong and Safe Are 3D Printed Walls?

People often wonder if 3d printed walls are strong enough to hold up a building. The answer is yes, many 3d printed walls are designed to be load bearing, meaning they can support weight just like traditional walls. The strength depends on the materials used and how thick the wall is.

Typically, 3d printed walls need to be thick enough to handle the weight and weather conditions of the area. Thickness can vary but usually ranges from several inches to over a foot for exterior walls. Builders carefully design walls to meet safety standards.

For smaller-scale 3d printed wall components or decorative elements, materials like ABS-GF, ABS-CF, and ABS-CF Core from Siraya provide reinforced strength and stability. ASA-GF is another great option that offers enhanced weather resistance, making it suitable for outdoor wall panels or accents.

However, these specialty filaments are generally not used for full structural 3d printed walls in construction, where concrete or composite materials remain the standard.

📌 For those curious about the strongest materials used in 3d printing, check out the article What is the Strongest 3D Printer Filament: Quick Guide to learn about durable options.

How Long Does It Take to 3D Print a Wall?

The time it takes to 3d print a wall depends on several factors such as the size of the wall, the printer’s speed, and the complexity of the design. Small walls or panels can be printed in a few hours, while larger walls for homes might take days.

Printing is usually faster than traditional building because the printer works continuously without breaks. However, finishing touches like curing (drying) time for the material are also important to consider.

📌 If you want to see real examples of 3d printing projects and how long they take, discover the article Creative 3D Printing Examples for Beginners for detailed insights.

How Much Does a 3D Printed Wall Cost?

The cost of a 3d printed wall varies depending on the materials, size, and printer used. Generally, 3d printed walls can cost less than traditional walls because they reduce labor and material waste. However, the initial investment in equipment and design can be higher.

Factors that affect cost include:

- Type of concrete or composite material used

- Wall thickness and size

- Complexity of the design and finishing details

Builders often find that 3d printing walls is a smart choice for saving money on large projects or custom designs.

Challenges and Limitations of 3D Printed Walls

While 3d printed walls have many benefits, there are still some challenges to keep in mind. One issue is that the technology is new and not yet widely available everywhere. This means fewer contractors have experience with it.

Another challenge is the surface finish. Sometimes 3d printed walls need extra smoothing or coating to look perfect. Weather resistance can also be a concern if the wrong materials are used.

Builders and homeowners should carefully consider these factors before choosing 3d printed walls. Despite these challenges, the technology is improving quickly and becoming more reliable.

Durability of 3D Printed Walls Against Weather

3d printed walls can be very durable and withstand different weather conditions if built properly. Many 3d printed homes have been tested to resist storms, rain, and wind. The strength of the wall material and thickness play a big role in how well the wall holds up.

Some 3d printed walls have even been designed to resist natural disasters like tornadoes. These walls often use reinforced materials to increase safety.

Conclusion

3d printed walls are an exciting innovation that is changing the way buildings are made. They offer faster construction, cost savings, and unique design options while maintaining strength and safety. Although there are some challenges, the technology is advancing quickly and becoming a smart choice for many projects.

For more helpful guides and tips about 3d printed walls and other 3d printing topics, be sure to visit Siraya. They offer high quality products like 3d printing filaments, resins for 3d printing, and platinum silicone crafting materials to help you create superior projects every time.

Frequently Asked Questions About 3D Printed Wall

Are 3D printed walls load bearing?

Yes, many 3d printed walls are designed to be load bearing, meaning they can support the weight of a building. The strength depends on the materials and thickness used. Engineers make sure these walls meet safety standards before construction.

What is the average cost of a 3D printed house?

The cost varies widely but 3d printed houses often cost less than traditional homes because of reduced labor and waste. Prices depend on size, materials, and location. Some projects have been completed for tens of thousands to hundreds of thousands of dollars.

What is the 45 degree rule for 3D printing?

This rule means that angles greater than 45 degrees may need support structures during printing to avoid sagging. It helps create strong and accurate prints without defects. While more relevant to small 3d prints, it can apply to wall details too.

How thick does a 3D printed wall need to be?

Thickness depends on the wall’s purpose but usually ranges from a few inches for interior walls to over a foot for exterior load-bearing walls. Proper thickness ensures strength, insulation, and durability.