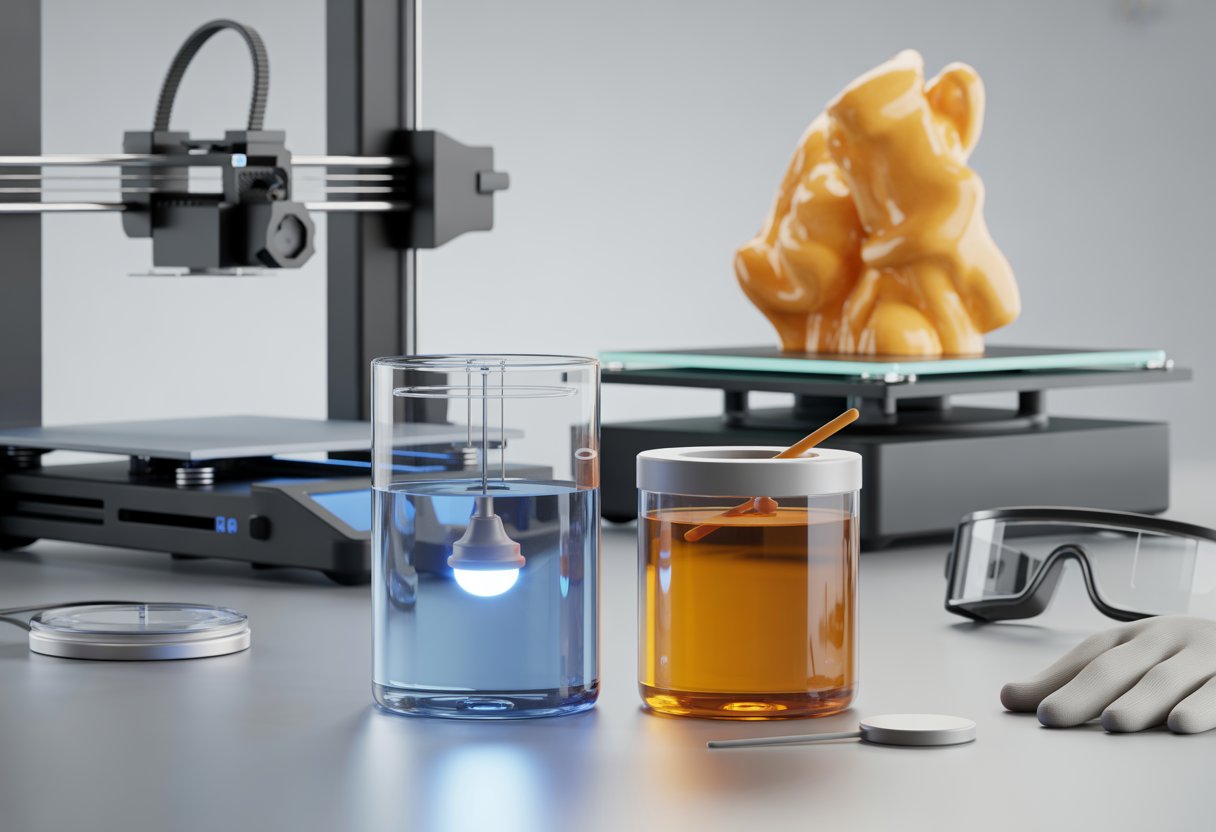

When you compare UV resin vs epoxy for 3D printing, the biggest difference comes down to how each one cures and what kind of finish you want. UV resin hardens fast under a UV light, making it great for small, detailed prints.

Epoxy takes longer to cure but gives strong, durable results that work better for larger or load-bearing parts.

Each type has its own tools, cost, and look, so knowing when to use each saves time and money. Keep reading to find out which fits your next project best.

Key Takeaways

- UV resin cures fast and works well for detailed prints.

- Epoxy offers stronger, longer-lasting results.

- Choosing the right resin depends on project size, tools, and budget.

Experiment with flexible and durable materials from our Flexible Resin 3D Printing Collection for smooth, detailed finishes.

Summary Table: UV Resin vs Epoxy for 3D Printing

|

Category |

UV Resin |

Epoxy Resin |

|

Composition |

Single-component photopolymer |

Two-part system (resin + hardener) |

|

Curing Method |

UV light exposure (365–405 nm) |

Chemical reaction (no light needed) |

|

Cure Time |

Seconds to minutes |

Hours to days |

|

Flexibility |

Brittle, less impact-resistant |

More flexible and durable |

|

Finish |

Very glossy, smooth, clear |

Glossy to glass-like; thicker coat |

|

Ideal Project Size |

Small, detailed prints |

Medium to large projects |

|

Durability |

Moderate; prone to cracking |

High; resists heat and impact |

|

Shelf Life |

Shorter |

Longer |

|

Ease of Use |

Simple, no mixing required |

Requires precise mixing and timing |

|

Best Uses |

Miniatures, jewelry, coatings |

Coatings, bonding, structural parts |

|

Cost Efficiency |

Higher cost per ounce |

More economical for large-scale use |

|

Environmental Factors |

Low fumes; light exposure needed |

Mild odor; more chemical waste |

|

Detail & Precision |

Excellent fine detail |

Good surface leveling for large areas |

|

Yellowing Resistance |

May yellow over time |

More UV stable and long-lasting |

|

Overall Advantage |

Fast curing and high detail |

Stronger, more durable, versatile |

Explore the differences in filament materials with What Is PETG Filament: A Guide in 3D Printing Applications.

Core Differences Between UV Resin and Epoxy for 3D Printing

UV resin and epoxy resin both make strong, glossy prints but work in very different ways. They vary in how they’re made, how they cure, and what kinds of 3D printing projects they fit best.

Chemical Composition and Structure

UV resin is a photopolymer, meaning it hardens when exposed to ultraviolet light. It contains light-sensitive monomers and a photo-initiator that starts the curing process.

The formula is designed for quick, layer-by-layer curing, which makes it ideal for resin 3D printers.

Epoxy resin, on the other hand, is a two-part system that mixes resin and hardener. When combined, they create a chemical reaction that forms strong, durable plastic.

Epoxy’s structure gives it excellent adhesion and resistance to wear, but it takes longer to harden.

|

Property |

UV Resin |

Epoxy Resin |

|

Components |

Single liquid |

Two-part mix |

|

Reaction Type |

Light-activated |

Chemical (resin + hardener) |

|

Flexibility |

More brittle |

More flexible |

|

Shelf Life |

Shorter |

Longer |

How Each Resin Cures

You cure UV resin by shining a UV light or placing it under sunlight. It hardens in seconds to minutes, depending on the light strength and resin thickness. This fast process is perfect for quick printing or small detailed parts.

Epoxy resin cures through a chemical reaction between the resin and hardener. It doesn’t need light but takes hours or even a full day to set.

The slower cure gives you more working time and helps reduce warping or bubbles in large coatings.

Suitability for 3D Printing Projects

You’ll often use UV resin in resin-based 3D printers, like SLA or DLP machines. It gives smooth surfaces, sharp details, and fast print times. However, it can be brittle, so it’s not ideal for parts that need to bend or handle stress.

Epoxy resin is usually used to coat or strengthen printed pieces rather than for direct printing. It helps seal porous prints and adds durability.

You can also use it to fill gaps or give a clear, glossy finish to models.

For heat‑tolerant projects, explore the Heat Resistant Filament Collection built for performance under pressure.

Curing Methods and Required Tools

Curing resin for 3D prints depends on light, heat, and time. You need the right tools and setup to make sure the resin hardens evenly and stays strong after printing.

UV Lamp and Light Exposure

UV resin hardens when exposed to ultraviolet light. You’ll need a UV lamp or curing station that gives off the right wavelength, usually around 365–405 nm.

Most desktop UV lamps work well for small prints, while larger models help cure bigger pieces evenly.

Keep your print about 2–6 inches from the light for even exposure. Turning the piece every few minutes helps avoid soft spots.

If you use sunlight, it can work but takes longer and depends on weather. A controlled lamp setup gives you faster and more consistent results.

|

Tool |

Purpose |

Notes |

|

UV Lamp |

Hardens UV resin |

Best for small parts |

|

Curing Station |

Even light exposure |

Great for detailed prints |

|

Sunlight |

Backup option |

Slower and less consistent |

Mixing and Timing with Epoxy

Epoxy resin cures through a chemical reaction between resin and hardener, not light. You mix the two parts in a set ratio, usually 1:1 or 2:1, depending on the brand.

Stir slowly to avoid bubbles. Once mixed, the curing clock starts, so you need to work quickly.

The pot life, or open time, can range from 20 minutes to several hours.

Use mixing cups, stir sticks, and protective gloves. Keep your workspace level so the resin sets evenly.

If you pour too thick, the resin can overheat or cure unevenly.

Environmental Factors Affecting Curing

Temperature, humidity, and airflow all affect curing. UV resin cures best at room temperature with low humidity. Cold or damp air can slow down hardening or cause a cloudy finish.

Epoxy needs a stable temperature between 70–80°F (21–27°C) for best results. If it’s too cold, the resin may stay sticky.

Keep dust and debris away while curing. Even small particles can stick to the surface and ruin the finish.

A clean, dry, and well-lit area helps your prints cure smoothly and look clear.

Discover how silicone compares to resin by checking our guide: Cleaning and Sterilizing Siraya Tech Defiant Silicone Parts.

Finish, Durability, and Appearance

Both UV resin and epoxy resin can make your 3D prints look smooth and shiny. They differ in how glossy they appear, how well they handle scratches, and how long they keep their look without yellowing or cracking.

Glossy Finish and Transparency

UV resin cures fast under a UV light, giving you a high-gloss finish that looks clear and glassy. It’s great when you want to highlight small details or give a polished look to miniatures and models.

Epoxy resin also creates a glossy surface, but it takes longer to cure and may need polishing for the same shine. It usually has a slightly thicker coat, which helps hide small print lines.

If you want a quick, bright surface, UV resin works best. If you prefer a deep, smooth coat that levels out uneven prints, epoxy resin gives you more control.

|

Resin Type |

Gloss Level |

Cure Time |

Notes |

|

UV Resin |

Very glossy |

Minutes (under UV) |

Best for small parts |

|

Epoxy Resin |

Glossy to glass-like |

Hours to days |

Best for large prints |

Scratch and Impact Resistance

Epoxy resin forms a harder, more durable coating once it fully cures. It resists scratches better and can handle light bumps or drops without chipping. This makes it a strong choice for parts that get handled often.

UV resin, while tough, tends to be more brittle. It can crack or dent more easily if the layer is thin or the print flexes. You can reduce this by applying thicker coats or using flexible UV resin blends.

Long-Term Stability

Over time, epoxy resin stays stable and less likely to yellow if kept out of direct sunlight. It bonds well to most 3D print materials, keeping the surface sealed and smooth for years.

UV resin can yellow faster when exposed to UV light or heat. Some brands add UV blockers to slow this down, but it still needs careful storage and display.

If your prints sit in bright or warm areas, epoxy resin keeps its look longer. For short-term or indoor projects, UV resin stays clear and glossy without much upkeep.

Try the Silicone Collection for flexible, high‑temperature molding and casting applications.

Applications and Project Suitability

Each resin type fits different 3D printing and crafting needs. UV resin works best for small, detailed prints, while epoxy resin handles larger, stronger, or more durable projects.

Best Uses for UV Resin in 3D Printing

You’ll find UV resin great for small, detailed models that need smooth surfaces and quick results. It cures fast under a UV lamp, so you can finish prints in minutes instead of hours.

This makes it handy for miniatures, jewelry, and prototypes where fine detail matters more than strength.

You can also use it for coating or adding clear finishes to prints.

|

Feature |

UV Resin Benefit |

|

Cure Time |

Seconds to minutes under UV light |

|

Ideal Size |

Small to medium prints |

|

Finish |

Smooth, glossy, high detail |

|

Use Cases |

Miniatures, decorative parts, quick fixes |

Because UV resin cures layer by layer, it’s not ideal for thick or large items—it can stay soft inside if light doesn’t reach every part.

When to Choose Epoxy Resin

Use epoxy resin when you need strength, durability, or larger size. It cures slowly, giving you more working time to mix, pour, and adjust before it hardens.

Epoxy resin works well for functional parts, coatings, and bonding printed pieces together. It also resists heat and impact better than UV resin.

You can tint or fill it with color, glitter, or powders to create custom looks. It’s also safer for thicker pours since it cures evenly without needing light exposure.

|

Feature |

Epoxy Resin Advantage |

|

Cure Time |

Hours to days |

|

Ideal Size |

Medium to large projects |

|

Strength |

High durability |

|

Use Cases |

Repairs, coatings, structural parts |

River Tables and Large-Scale Projects

For river tables and large-scale resin applications, epoxy resin is the clear winner. You can pour it deep—sometimes several inches thick—without worrying about uneven curing.

It flows smoothly into molds or wood channels, creating the clear “river” look that’s popular in furniture design. You can mix pigments or metallic powders for color effects.

UV resin can’t handle deep pours because it needs light to cure. It’s better for small surface details or touch-ups, not full table pours.

Learn safe handling and curing techniques by reading our article: Proper Handling of UV Curable 3D Printing Resins.

Cost, Accessibility, and Environmental Considerations

When choosing between UV resin and epoxy for 3D printing, you’ll notice differences in price, how easy they are to get started with, and how safe or eco‑friendly they are.

Each type fits different needs depending on your budget, workspace, and comfort level with handling chemicals.

Material and Equipment Costs

UV resin usually costs more per ounce than epoxy resin. You also need a UV lamp to cure it, which adds to the upfront cost.

The lamp’s price depends on its power and size. Smaller lamps for jewelry or small prints are cheaper, while larger curing stations for 3D prints cost more.

Epoxy resin is sold in larger kits and often ends up cheaper for big projects. You mix two parts—resin and hardener—so you get more volume for the price.

However, epoxy takes longer to cure, which can slow down your workflow if you print often. If you only make small, detailed parts, UV resin’s higher cost might still make sense. But for larger prints or batch jobs, epoxy resin usually gives you more value.

Ease of Use for Beginners

UV resin is simple to use. You pour it, shape it, and cure it under a UV lamp in minutes. There’s no mixing, so you don’t have to worry about wrong ratios or sticky results. This makes it great for quick fixes or coating 3D prints.

Epoxy resin takes more steps. You must measure and mix the two parts evenly. If you get the ratio wrong, it may not harden right. It also gives you more working time before it cures, which helps when covering large prints or adding layers.

For beginners, UV resin feels easier and less messy.

Environmental and Safety Factors

Both resins need careful handling. Uncured UV resin can irritate your skin or eyes, so always wear gloves and eye protection.

Work in a ventilated area and avoid direct contact. Once cured, it’s safe to touch and doesn’t release fumes.

Epoxy resin can release mild odors while mixing. Some types contain chemicals that cause skin sensitivity. You should wear gloves and a mask when working with it. Dispose of leftover resin properly—don’t pour it down the drain.

UV resin cures fast under light and doesn’t give off strong fumes. Epoxy, while more durable, may have a bigger environmental impact due to longer curing times and chemical waste.

Achieve strength and reliability with the Strong Filament Collection, perfect for demanding builds.

Bottom line

When comparing UV resin vs epoxy, the right choice depends on your project’s needs. UV resin cures quickly under UV light, making it ideal for small crafts, jewelry, and detailed coatings.

Epoxy resin, however, offers greater durability, volume flexibility, and a longer working time—perfect for larger pours and structural applications. Both have unique advantages in clarity, strength, and finish.

Understanding their differences ensures better results and smoother workflows. For dependable, high-performance materials that elevate your 3D printing and crafting projects, check out Siraya Tech’s filaments and experience premium quality.

Deepen your understanding of resin performance in A Deep Dive into Resin 3D Printers and Printing Process.

Frequently Asked Questions

What's the difference in curing time between UV resin and epoxy?

UV resin cures fast when you shine a UV light on it—usually in minutes. Epoxy takes much longer, often several hours or even a day, to fully harden.

Can I use UV resin for my 3D prints just like epoxy?

You can use UV resin for 3D prints, but it fits best for small or detailed parts. Epoxy works better for coating, bonding, or large pieces that need more working time.

What are the pros and cons of using UV resin compared to epoxy in 3D printing?

UV resin cures quickly and gives smooth, clear results. But it can be brittle and needs light to harden. Epoxy is stronger and more flexible, but it takes longer to cure and can be messier to mix.

Is UV resin more durable than epoxy for 3D printed objects?

No, epoxy is usually more durable. It handles stress and heat better, making it good for functional parts.

UV resin is harder but can crack more easily under pressure.

How do the costs of UV resin and epoxy compare for 3D printing projects?

UV resin often costs more per ounce, especially since you need a UV lamp to cure it. Epoxy is cheaper for large projects and comes in bigger quantities.

Are there any safety concerns I should be aware of when choosing between UV resin and epoxy?

Both can irritate your skin and eyes, so wear gloves and work in a well-ventilated area. UV resin also needs eye protection from the curing light.

Always follow the safety directions on the product label.