Recently viewed

Elastic filament revolutionizes 3D printing by creating parts that stretch, compress, and return to their original shape like rubber bands or springs. At Siraya Tech, our elastic filament collection is engineered for makers who need maximum stretch and recovery—think custom springs, shock absorbers, and expandable components that perform under repeated stress. With superior elasticity and engineered printability, these materials let you create functional parts that were previously impossible with traditional manufacturing.

Elastic Filament Engineered for Maximum Stretch and Recovery

When your project demands true elastic behavior with exceptional stretch ratios, elastic filament delivers performance that outperforms standard flexible materials.

- Exceptional elongation at break up to 700% for maximum stretch capability

- Superior elastic recovery returns parts to original dimensions after stretching

- Consistent elastic modulus provides predictable spring-like behavior

- Excellent memory properties maintain elasticity through thousands of cycles

- Optimized polymer chains deliver rubber-like performance with thermoplastic convenience

Outstanding Durability Under Repeated Stress

True elastic performance means handling continuous stretching and compression without losing properties or developing stress fractures over time.

- High fatigue resistance for parts used in demanding applications

- Excellent tear propagation resistance prevents failure at stress points

- Temperature stability maintains elasticity across wide operating ranges

- Chemical resistance to oils, solvents, and environmental exposure

- UV-stable formulations prevent degradation and property loss from sunlight

Complement your elastic printing projects with our Fibreheart ASA filament family for rigid structural components requiring outdoor durability.

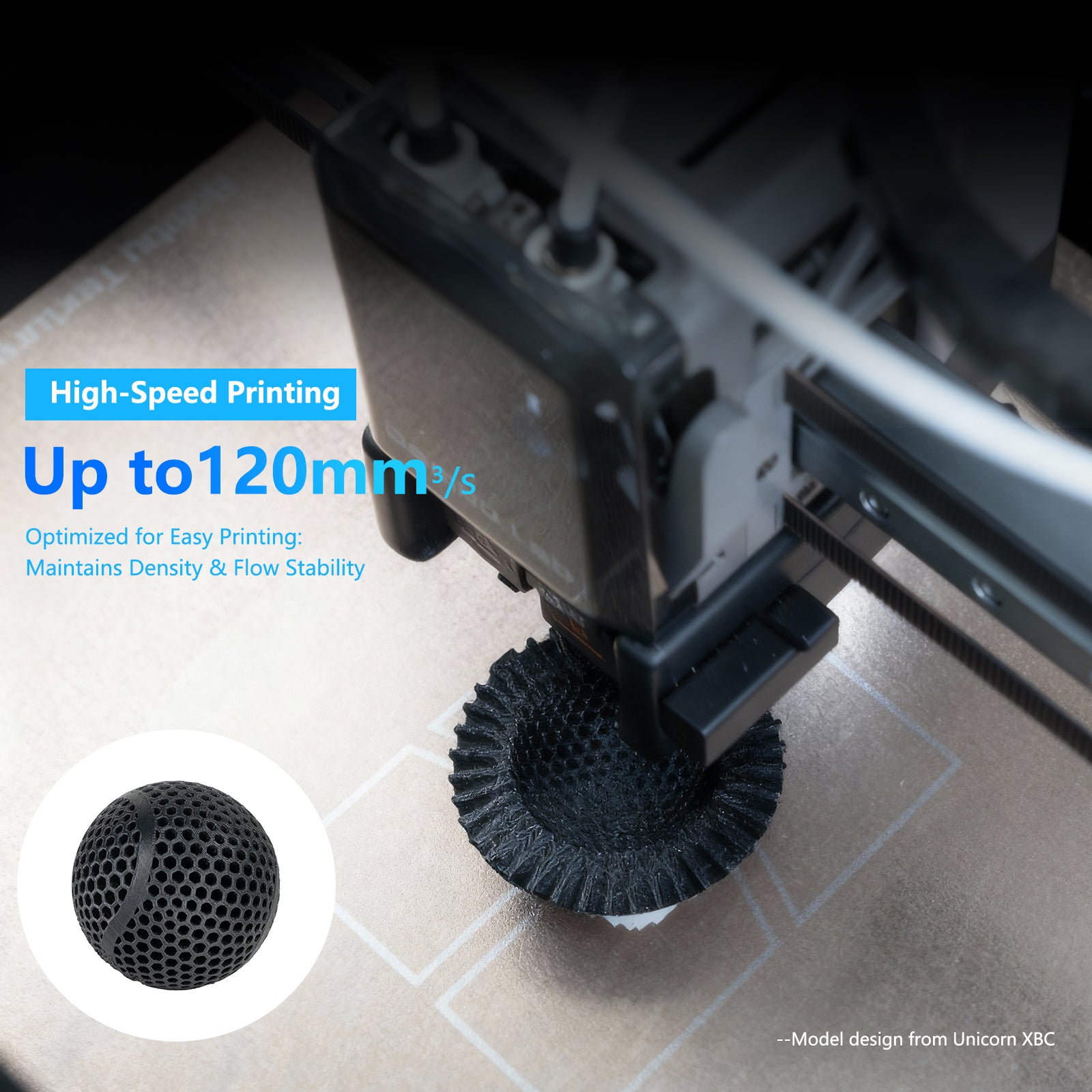

Reliable Printing Performance Despite Extreme Elasticity

Advanced elastic properties don't have to mean printing nightmares. Our elastic filament is formulated to extrude consistently while maintaining maximum stretch capability.

- Controlled flow characteristics prevent jamming and under-extrusion

- Optimized layer adhesion creates unified parts despite extreme flexibility

- Reduced stringing and oozing for cleaner finished surfaces

- Compatible with direct drive extruders and properly configured systems

- Stable processing temperatures for consistent print quality

Perfect for Applications Requiring True Elastic Behavior

Elastic filament excels where other flexible materials fail, creating parts that actively stretch and compress like traditional elastic components.

- Custom springs and shock absorbing components

- Expandable bands, straps, and fastening systems

- Vibration dampening mounts and isolation components

- Fitness equipment requiring stretch and resistance

- Mechanical systems needing elastic energy storage and release

For precision applications requiring exceptional strength, explore our engineering resin collection for high-performance prototyping.

Why Siraya Tech Elastic Filament Delivers Superior Performance

True elastic behavior requires precise polymer engineering and quality control. Our elastic filament provides consistent stretch properties through advanced formulation.

- Carefully controlled molecular weight distribution ensures consistent elasticity

- Quality-tested batches guarantee repeatable stretch and recovery properties

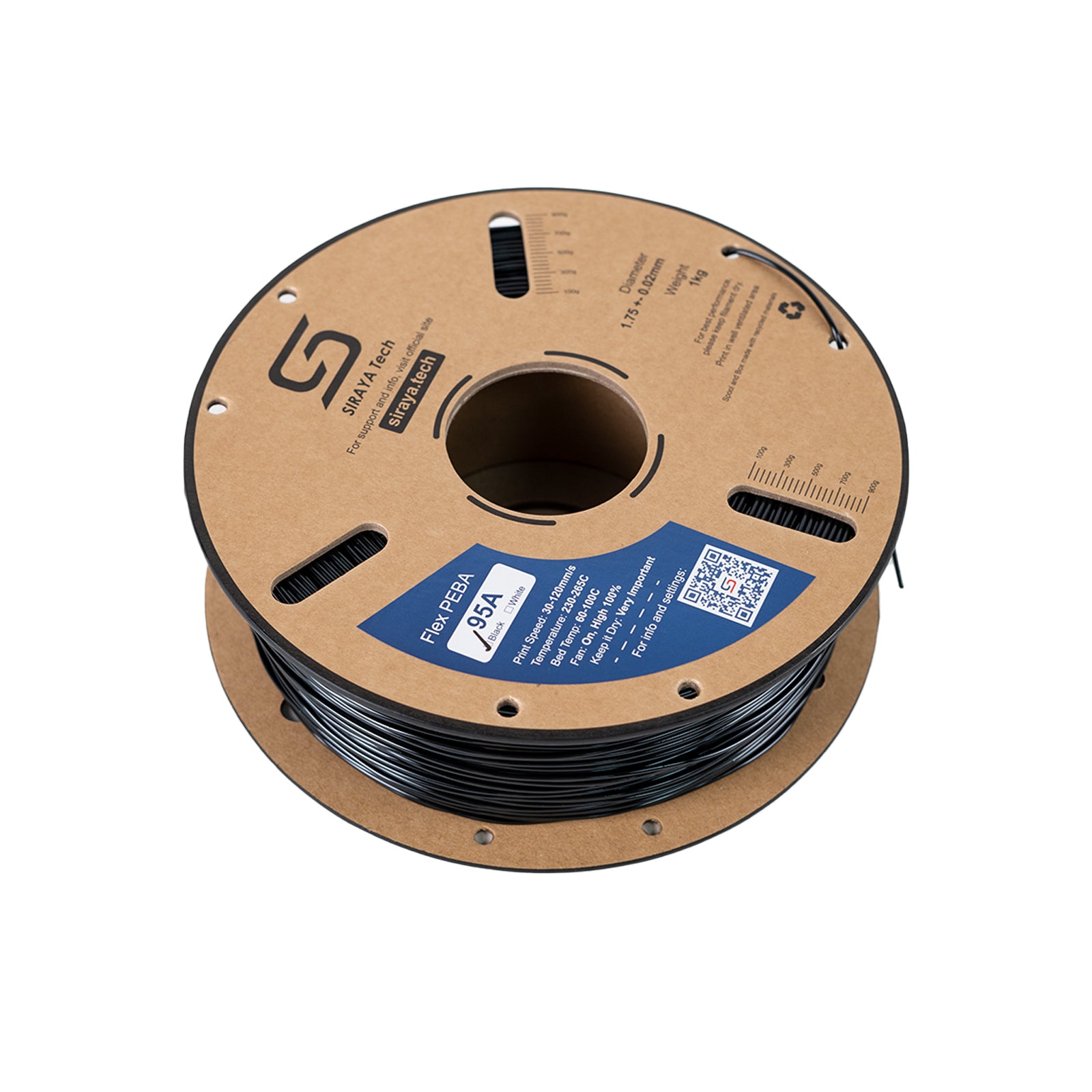

- Moisture-resistant packaging maintains material integrity until use

- Comprehensive printing guidelines optimize setup for best results

-

Technical support for challenging applications and troubleshooting

For flexible resin applications requiring similar elasticity, discover our flexible resin Tenacious family collection.

Revolutionary Applications Across Industries

From automotive to consumer products, elastic filament enables designs that actively use stretch and compression as functional elements rather than just flexibility.

- Automotive suspension components and vibration isolation systems

- Medical devices requiring controlled compression and expansion

- Consumer products with expandable or adjustable features

- Industrial machinery requiring elastic coupling and dampening

-

Custom athletic equipment with personalized resistance levels

FAQs About Elastic Filament

What is an elastic filament?

Elastic filament is a specialized 3D printing material designed to stretch significantly and return to its original shape, like a rubber band. Unlike standard flexible filaments that bend, elastic filament actively stretches under tension and recovers completely. It's engineered for applications requiring true elastic behavior rather than just flexibility.

What is the stretchy filament called?

Stretchy filament is commonly called TPU (thermoplastic polyurethane), TPE (thermoplastic elastomer), or elastic filament depending on the specific properties. Elastic filament specifically refers to materials with maximum stretch capability and recovery. These materials are also sometimes called elastomeric filaments or flexible filaments, though elastic filament offers superior stretch ratios.

Is PLA or PETG more flexible?

Neither PLA nor PETG are flexible materials—both are rigid thermoplastics. PLA is brittle and will snap under stress, while PETG has some toughness but lacks any elastic properties. For stretchy applications, you need dedicated elastic or flexible filaments like TPU, TPE, or specialized elastic materials designed for maximum stretch and recovery.

Is elastic filament thick or thin?

Elastic filament diameter follows standard 3D printing sizes (typically 1.75mm or 2.85mm), but the printed parts can be designed thick or thin based on application needs. Thinner printed sections will stretch more easily, while thicker sections provide more resistance. The filament itself maintains consistent diameter for reliable feeding and extrusion.